Suspended Hot Stamping PVC Ceiling Panel Production Line

Jiangsu Acemien Machinery Co., Ltd.- Product Type:PVC Board

- Board Layers:Multilayer

- Screw No.:Double-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008, UL, QS, GMP

Base Info

- Model NO.:ACEMIEN-002

- Customized:Customized

- Condition:New

- Transport Package:Plastic Film Package and Loaded Into The Container

- Specification:28m*5m*5m

- Trademark:Acemien

- Origin:Jiangsu Province

- HS Code:84772090

- Production Capacity:1000 Sets,Year

Description

Basic Info.

Model NO. ACEMIEN-002 Customized Customized Condition New Transport Package Plastic Film Package and Loaded Into The Container Specification 28m*5m*5m Trademark Acemien Origin Jiangsu Province HS Code 84772090 Production Capacity 1000 Sets/YearProduct Description

Suspended hot stamping pvc ceiling panel production linesuspended hot stamping pvc ceiling panel production line with hot stamping extrusion machine line can produce different colors and patterns wall panel, which can be used as the ceramic wall panel. The PVC wall panel, ceiling panel can make your room tidy and warm and attracive with different patterns.

First please seel below wall panel pictures, which you can see widely in daily life.

The suspended hot stamping pvc ceiling panel production line indoucing below parts: The main extruder, the mould die, the calibriator table , the haul off unit, the cutter system and the receiving table.

then i will introduce you the suspended hot stamping pvc ceiling panel production line every parts one by one.

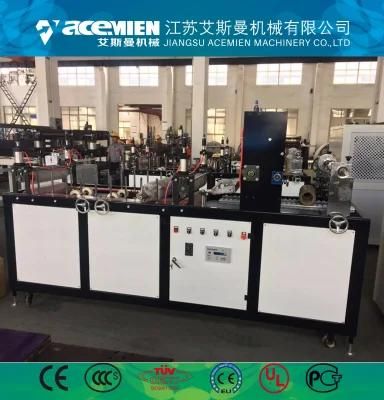

This is the suspended hot stamping pvc ceiling panel production lineSJZ55/110 conical twin-screw extruder. Which is used to push the material forward to the mould die.

Below is the specifications of the suspended hot stamping pvc ceiling panel production line SJZ55/110 conical twin-screw extruder

Extrusion capacity 120-150kg/h

Screw Diameter conical 55/110 mm

Material of screw: 38CrMoAl

Surface treatment: Nitride processing, thickness: 0.6 ~ 0,8mm, Polishing

Rotating speed (counter rotating): 1-40 rpm/min

Barrel Inner processing: Nitride with thickness: 0.6 ~ 0.8mm

Heating zones: 4

Heating mode: Cast alumina + stainless steel covering

Heating power: 18 Kw

Cooling mode: Air fans: 3 Sets

Driving motor Motor power: 30Kw AC (SIEMENS)

Dosing feeding system Motor:1.1Kw Double screw forced feeding

Vacuum system

Vacuum pump: 2.2Kw,1 set

Vacuum degree = 0 ~ 0.075 Mpa

Adaptor

Material: #40steel Chrome plated40, inner convergent flow type

Connection method with die: clamping block + bolt

Pressure melt sensor and thermocouple

Main electric cabinet

Inverter: ABB; Contactor : Schneider; Air Switch :LS;

Relay: Omron; Temperature controller: Omron

Self-protective system

Over current protective of motor

Over pressure protective of screw

Outer size and weight 2600×1500×2410mm 2200kg

This is the suspended hot stamping pvc ceiling panel production linemould.

The specifications is as below:

Material of mould: S2316, 3Cr17

Product width: 203mm

Thickness:8mm

Casted Aluminum heating plate

This is the calibrator table of the suspended hot stamping pvc ceiling panel production line.

Exterior dimension: Lx W x H: 4000x900x1000mm (adjustable)

Vacuum pump: 4 Kwx1set

Water pump: 3Kwx1set

Three direction adjustment : Forward and Backward with 0.75Kw motor

Range: ±500mm

Up and down, left and right manually adjusted

Range: up and down: ±150mm

Left and Right moving: ±50mm

With Infrared device, guarantee speed synchronously with Haul-off speed

This is the haul off system of the suspended hot stamping pvc ceiling panel production line, below is some specifications for your reference:

Haul-off speed: 0.5-5m/min;

Motor power: 1.5Kw×2sets

Caterpillar width: 300mm*1 Rows

Caterpillar length: 1800mm;

Pneumatic clamp;

ABB inverter

This is the laminiation system of the suspended hot stamping pvc ceiling panel production line for your reference.

Below is some specficiations for your reference:

This machine is used to hot stamping PET film or laminate PVC film on various panels

It has two function: hot stamping and laminating

Working thickness and width can be adjusted

Equipped with foil tension force control system

This machine is used online only

Max working width:300mm

Max working thickness 2-50mm

The suspended hot stamping pvc ceiling panel production line also has the blade cutter and the stacker system.

If you want to know more, please feel free contact me, i will send you more details and pictures,

because in this webiste, i can only upload 6 pictures.

I am Laura, working in Jiangsu Acemien Machinery Co,Ltd, Our factory is professional in design and make the extrusion system for wall panel, roofing sheet, and some plastic profiles and the flooring sheets. Mahcinery from our factory are working in China almost every city, and also aborad, we export many machines every years.

And we can offer you machine working inspecting and reference customer visiting,

so if you need this kind machine or be interested, please feel free contact me, now!

Add my whatsapp, or Email me an inquiry!

My name is Karry, please feel free contact me, please!

Whatsapp: +86 18913298068

Phone/ Wechat : +86 18205059535