110-350mm Double Wall HDPE Pipe Extrusion Corrugated Pipe Forming Machine

Qingdao Tongsan Plastic Machinery Co., Ltd.- After-sales Service:Engineer Over Seas

- Warranty:1 Year

- Type:Pipe Extruder

- Plastic Processed:PE

- Product Type:Extrusion Molding Machine

- Feeding Mode:One Feed

Base Info

- Model NO.:110-350mm

- Assembly Structure:Integral Type Extruder

- Screw:Single-Screw

- Engagement System:Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Don′t Exhaust

- Automation:Automatic

- Computerized:Computerized

- Transport Package:Packing

- Specification:110-350mm

- Trademark:Tongsan

- Origin:China

- HS Code:84772090

- Production Capacity:10 Sets,Month

Description

1 set Extruder for Double wall corrugated DWC pipe machine

Extruder for Double wall corrugated DWC pipe machine

Die head for 110-300mm HDPE double wall corrugated pipe machine

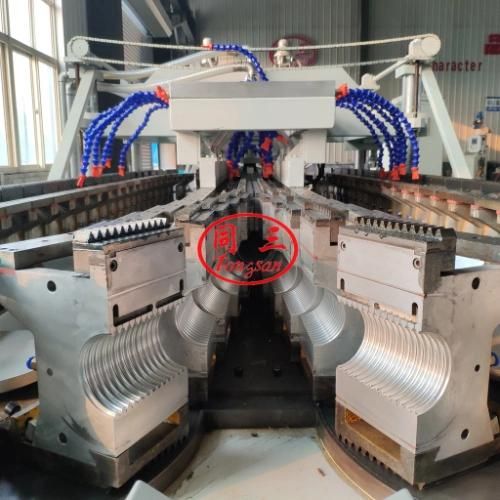

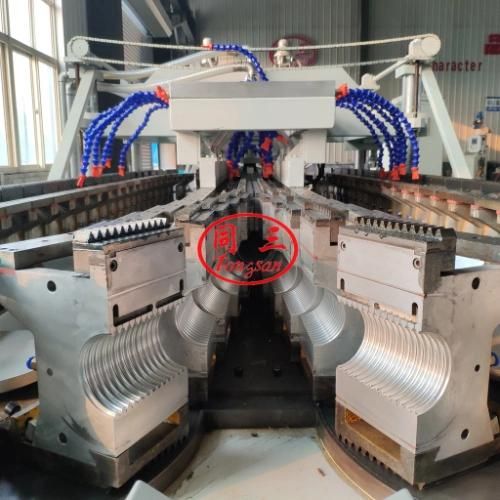

Mold blocks for 110-300mm HDPE double wall corrugated pipe machine

Mold for DWC double wall corrugated pipe machine48 pairs, Aluminum material, inner hollow with water cooling channel, with vacuum cooling

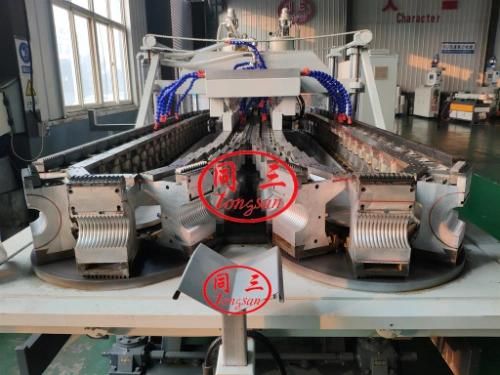

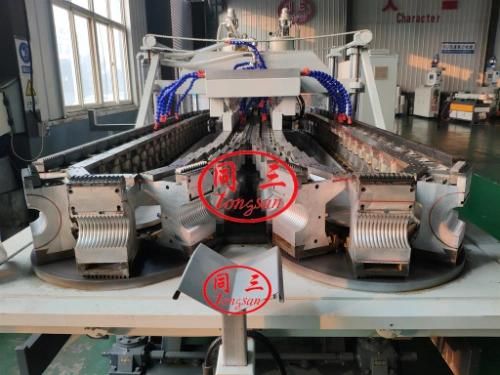

Forming machine for DWC double wall corrugated pipe machine

CUTTING MACHINE for 110-300mm HDPE double wall corrugated pipe machine

Product Stacker: 6 meters

PE/HDPE/PVC double wall corrugated pipe extrusion line adopts extruding and forming process, it has the features of reliable quality and high efficiency.Compared with other plastic pipe wall structure ,double wall corrugated pipe has excellent wall structure design,its low weight reach the lower production cost and improve the market competitiveness.The pipe is widely used in various field instead of concrete pipe and iron pipes,because it has excellent features such as:easy connected and accessories installed,and quality reliable.

2. Composite extrusion die head with specially helical structure to make the wall thickness unifom and stable production.

3. The forming machine has automatic power-off protection device.The forming machine an antomatically exit from the die head to avoid equipment failure in case of electrucity cut off suddenly.It also equipped with new type high transmitting ratio reducer, easy to operate and mainteance.

4. The corrugated forming system is in combination with water cooling and air cooling to sensure high production speed

continuously.Advanced programmable lubricating system minimizes the moulds wear so as to increase the life of service and ensure work smmothly with high precision to ensure the products quality stability.

5. Mould adopts specialy alumium alloy material and high precision die casting forming mould method,it has the advanages of high precision,high stremgth,good wearability and better heat dissipation performance.

6. Wave structure launched a comprehensive new optimization design to reach the best combination of high-rigidity and low weight.

Extruder for Double wall corrugated DWC pipe machine

Extruder for Double wall corrugated DWC pipe machine

Die head for 110-300mm HDPE double wall corrugated pipe machine

Mold blocks for 110-300mm HDPE double wall corrugated pipe machine

Mold for DWC double wall corrugated pipe machine48 pairs, Aluminum material, inner hollow with water cooling channel, with vacuum cooling

Forming machine for DWC double wall corrugated pipe machine

CUTTING MACHINE for 110-300mm HDPE double wall corrugated pipe machine

Product Stacker: 6 meters

PE/HDPE/PVC double wall corrugated pipe extrusion line adopts extruding and forming process, it has the features of reliable quality and high efficiency.Compared with other plastic pipe wall structure ,double wall corrugated pipe has excellent wall structure design,its low weight reach the lower production cost and improve the market competitiveness.The pipe is widely used in various field instead of concrete pipe and iron pipes,because it has excellent features such as:easy connected and accessories installed,and quality reliable.

Advantage of our Tongsan Plastic DWC double wall corrugated pipe machine

1. The main machine adopts special designed high efficiency screw which is specially used for polyolefin,it has the features of stable performance and high effiency.The machine has two independence extruders,which can realize both inside and outside layer with different material and colors.2. Composite extrusion die head with specially helical structure to make the wall thickness unifom and stable production.

3. The forming machine has automatic power-off protection device.The forming machine an antomatically exit from the die head to avoid equipment failure in case of electrucity cut off suddenly.It also equipped with new type high transmitting ratio reducer, easy to operate and mainteance.

4. The corrugated forming system is in combination with water cooling and air cooling to sensure high production speed

continuously.Advanced programmable lubricating system minimizes the moulds wear so as to increase the life of service and ensure work smmothly with high precision to ensure the products quality stability.

5. Mould adopts specialy alumium alloy material and high precision die casting forming mould method,it has the advanages of high precision,high stremgth,good wearability and better heat dissipation performance.

6. Wave structure launched a comprehensive new optimization design to reach the best combination of high-rigidity and low weight.