Zig Zag for Pet Flakes Recycling Production Plant

Zhejiang Boretech Environmental Engineering Co., Ltd.- Power:5.5+2.2+2.2kw

- Capacity:3000kg,H

- Dimension:6052*1550*2975mm

- Dust Separation Rate:>75%

- Transport Package:Film,Wooded Case,Regular Seaworthy Packing,Ect.

- Specification:3000 KG,H

Base Info

- Model NO.:XFZ-1200

- Trademark:BORETECH

- Origin:China

- HS Code:8414809090

- Production Capacity:10 Sets Per Month

Description

Basic Info.

Model NO. XFZ-1200 Trademark BORETECH Origin China HS Code 8414809090 Production Capacity 10 Sets Per MonthProduct Description

Zig Zag for PET Bottle Recycling System

Zig-zag separator can effectively separate the dust in the flakes, small plastic labels or film by taking advantage of the gravity and the special internal structure design.

The label aspirator separates the label and fine impurities from the flakes by the negative pressure which generated by blower, and can be used by multiple assembly.

| Model | Power(kW) | Capacity(kg/h) | Dimension(mm) | Dust Separation Rate(%) |

| FXZ-1200 | 7.7 | 3000 | 6500*2700*2400 | >70 |

| XFZ-1200 | 5.5+2.2+2.2 | 3000 | 6052*1550*2975 | >75 |

1,pre-sale support:

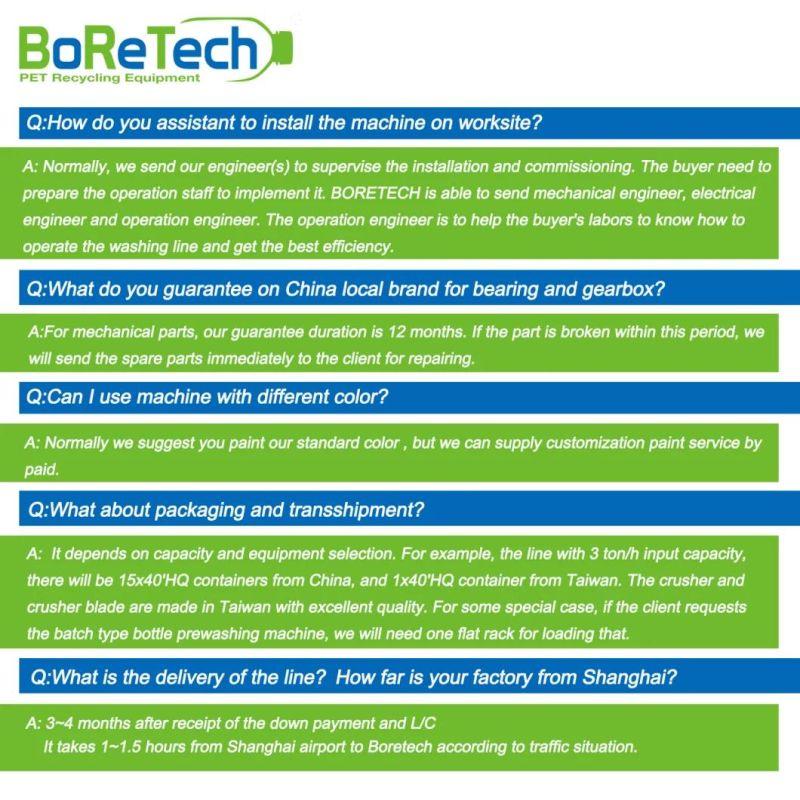

Normally we suggest you paint our standard color , but we can supply customization paint service by paid.

2,after-sale service:

Warranty:1 year for machinery,6 months for electrical.

For mechanical parts, our guarantee duration is 12 months. If the part is broken within this period, we will send the spare parts immediately to the client for repairing.

3,technical support:

Normally, we send our engineer(s) to supervise the installation and commissioning. The buyer need to prepare the operation staff to implement it. BORETECH is able to send mechanical engineer, electrical engineer and operation engineer. The operation engineer is to help the buyer's labors to know how to operate the washing line and get the best efficiency.

BoReTech is one of the major supplier of PET bottle recycling system in Asia . We uses the around 30 years of fiber making and bottle recycling experiences to manufacture PET Bottle recycling machine and configure Pelletizing line, Polyester Staple Fiber line, POY line and Bottle to Bottle Line. At present, we have supplied about 170 sets plant for more than 30 countries. Our customers in the US, Japan, EU manufacture food grade rPET resin for such well-known brand owner's such as Coca Cola, Niagara Bottling, Nestle, etc.

Boretech can help our customers to make right configuration of the machinery, and find the right position in the industries. The most important value is that we can help our customers to minimize the learning cost and to avoid making any mistake during investment.