Rubber Injection Molding Machine/Shoe Sole Making Machine

Wenzhou Chanyan Tech Co., Ltd.- Type:Injection Blow Molding

- Clamping Way:Mechanical

- Automation:Automatic

- Computerized:Computerized

- Certification:CE

- Delivery:Around Two Weeks After Receive Payment

Base Info

- Model NO.:CY-165

- Transport Package:Standard Export Packing

- Specification:3550*2020*3450 MM

- Trademark:CHANYAN

- Origin:China

- HS Code:8453200000

- Production Capacity:500 Sets,Month

Description

Basic Info.

Model NO. CY-165 Transport Package Standard Export Packing Specification 3550*2020*3450 MM Trademark CHANYAN Origin China HS Code 8453200000 Production Capacity 500 Sets/MonthProduct Description

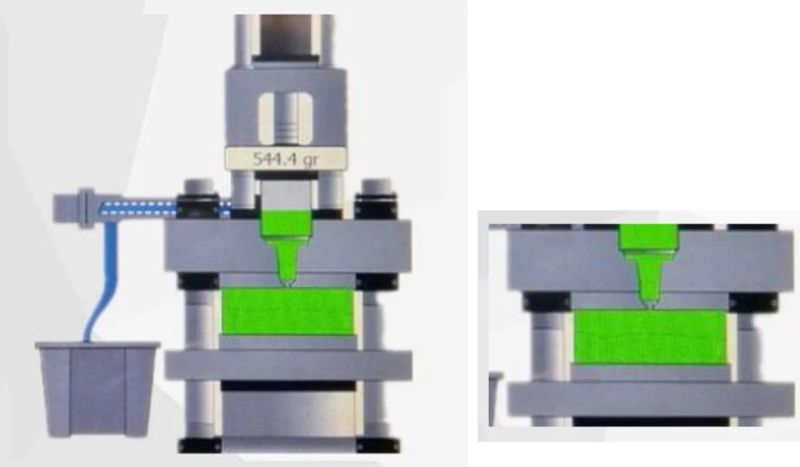

Rubber Injection Molding Machine/Shoe Making Machine| Model no: CY-165 | Product material: Rubber |

| Station: 2 | System pressure: 21MPa |

| Clamping Force: 1650KN | Total Power: 90KW |

| Clamping Stroke: 300mm | Mold Size: 400~440mm*300~330mm |

| Injection Volume: 1000CC | Machine Weight: 10500KG |

| Heating Power: 12*2KW | Machine Sizes: 3550mm X 2020mm X 3450mm |

Features:

1.The whole machine is designed and manufactured strictly follow the CE requirements of the EU market.ensure the safety of workers' operation and equipment operation.

2.Light curtain protection for workersThere are safety light curtains on the front and side of the machine. Minimize the possibility of injury to workers.

3.Unique heating plate design.Well reduced the heat transfer from the mold to the machine and environment, reduces energy consumption, and reduces the temperature of the worker's operating environment.

4.Lower labor intensity.Fully automated feeding, weighing and injection molding, reduce the labor intensity, reduce technical requirements of workers.

5.The mold investment is a big cost. inorder to meet the quickly delivery,usually we should have to open more molds for the same size.

While using CY-165 sole machine,since our speed is 2 twice higher with the same size mold, we can reduce the mold cost up to 65%.Our mold is fixed on the heating plate,the mold opening and closing are well controlled by the machine. Which will reduce the mold damage, can also increase the service life of mold.

We are using the aluminum mold for mass production. which can be recycled easily and still have high salvage value when the molds are no longer used.