PS Plastic PE Films Recycled PP Scraps Extrusion Melting Single Double Screw Die Head ...

Jiangsu Aceextech Machinery Co., Ltd.- After-sales Service:24 Hours on Line

- Warranty:13 Months

- Raw Material:PE

- Screw:Single-Screw

- Inverter:Inverter

- Electromagnetic Heater:Electromagnetic Heater

Base Info

- Model NO.:KCP100

- Automation:Automatic

- Computerized:Computerized

- Certification:CE

- Condition:New

- Cavity:Single Cavity

- Gearbox:High Torque Vertical Type

- Bearings:NSK,SKF

- Motor Brand:Weg, Siemens

- Extrusin Speed:1.0-2.0m,Min

- Screw and Barrel:Bimetallic Barrel & Screw

- PLC Controller:Siemens,Schneider

- Transport Package:Wood Pallet and Film Covered

- Specification:920mm,1100mm,1130mm

- Trademark:KITECH

- Origin:China

- HS Code:84772010

- Production Capacity:30-50 Sets, Year

Description

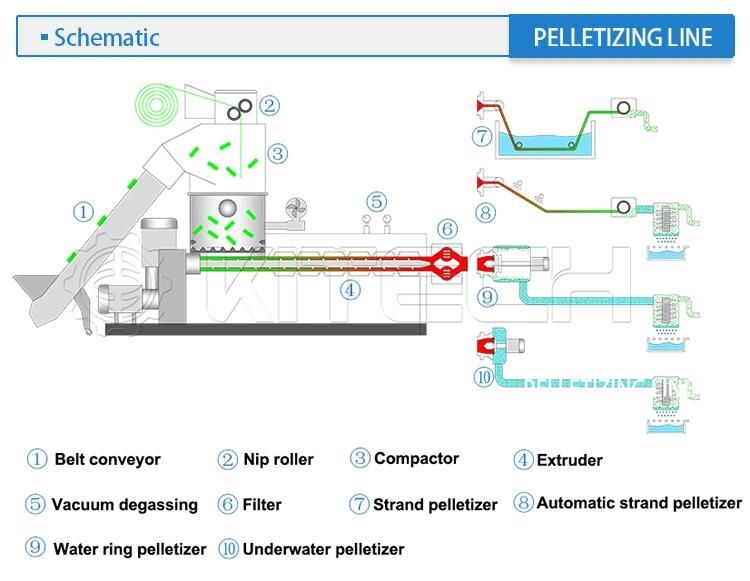

Working principle of KCP Plastic recycling Machine:

Basic data of KCP Plastic recycling Machine:

Specifications of KCP Plastic Recycling Machine:

*Feeding materials into compacting room by conveyor automaticlly.

*Speed possible controlled by inverter

*Metal detector optional

*Rotator and stationary blades are combined to cut up the materials,

*Crushes, dries and compacts the material in one step,

*Guide structure directs the material into extruder screw.

*A specialized single screw extruder applied to gently melt the pre-compacted material.

*The plastic scraps will be well melted, plasticized in the extruder.

*With double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiency, especially suitable to heavy printed film and material with some water content.

*Single Screw extruder melts the material,

*Double-zone vacuum degassing system,

*Self protective system,

*A single-plate double-station screen changer or double-plate four-station installed on head of extruder filtrates the melt.

*Build in hydraulic control.

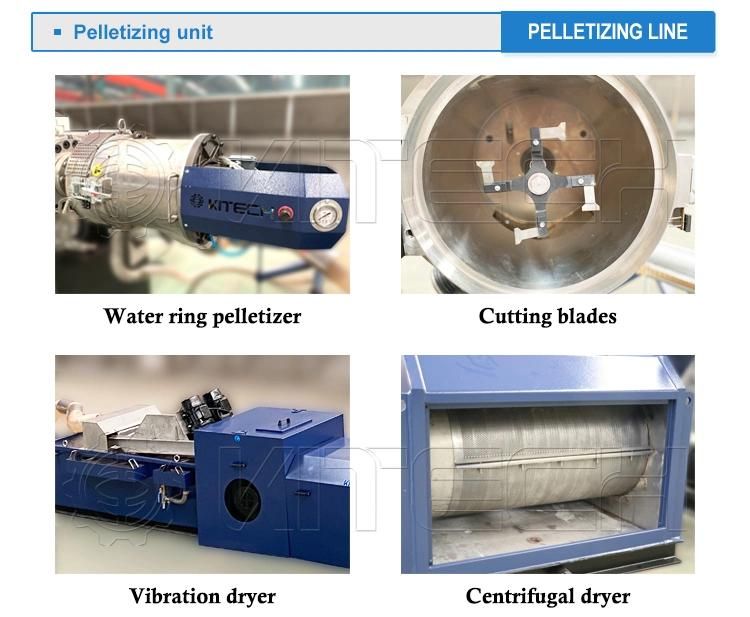

*Die-face water ring pelletizing system is a standard pelletizing method,

*Self-adjusting pelletizing,

*RPM of rotator blades is automatic based on melt extruding pressure,

*Dewatering vibration sieve combining with horizontal-type centrifugal dewatering have a good drying efficiency.

*PLC/HMI Controlling system,

*All electrical units mounted in a steel cabinet,

*All heaters equip with Ammeters,

*Safety interlock principle applied in the system,

*All electrical units: LS, Schneider, Siemens and ABB.

Advantages of Our KCP Plastic Recycling Machine:

*Ability:KITECH pelletizing system with superior quality which have high productivity for PP/PE/PS/ABS/BOPP/CPP plastic could get high property output pellets.

*Stability:

The pelletizing system is available for 24 hours working non-stop operation.

*Efficiency:

The pelletizing system have very low consumption values for electricity, water and labor.

*Control:

Intelligent automatic control of pelletizing system reduces the labor operation, makes the whole system easier and more reliable to control.

*Service:

Consistently quick and careful service in pre-sales and after-sales process. Overseas installation, commissioning and training are available.

Service and support:

*Before-sale:

Introduce products professional

Project engineering

*During manufacturing:

Provide layout and engineering conditions

Inform the schedule of production

Make sure the product designed in accordance with technical document

Test machine before delivery

Provide photos before shipping

*After-sale:

Build customers database. All machines are traceable.

Overseas installation, commissioning and training are available

Speed up service and spare parts supply.

Visit customers and make quality trace periodically

Our Successful Subject:

Contact to KITECH:

KITECH MACHINERY CO., LTD

Add:No.7 Jiulong Industry Park, Jinfeng Town, Zhangjiagang City Jiangsu, China.

Service and support:

*Before-sale:

Introduce products professional

Project engineering

*During manufacturing:

Provide layout and engineering conditions

Inform the schedule of production

Make sure the product designed in accordance with technical document

Test machine before delivery

Provide photos before shipping

*After-sale:

Build customers database. All machines are traceable.

Overseas installation, commissioning and training are available

Speed up service and spare parts supply.

Visit customers and make quality trace periodically

About KITECH:

Kitech is a creative company, focusing on R & D of plastic extrusion system, and providing the equipments and solutions for plastic pipe, profile, tile, sheet and board.

Kitech products fulfill the needs of users in a very direct way due to over 25 years of knowledge and experience in plastic extrusion field, which also helps us to contribute actively to the success of customers by offering sustainable solutions that meet industry needs.

Kitech offers a complete portfolio of support and consulting services all the time, from project engineering to custom financing solutions, after sales service at its best, ongoing production optimization, training and advisory services, even end product development.

Why KITECH:

- Specialized R & D team involved in plastic extrusion industries over 25years.

- Ability to provide the customized plastic extrusion solutions.

- Complete sales system covering the pre-sales, sales and after-sales service jobs.

- Professional sales team with local language speaking ability for English, Portuguese, Spanish, Turkish and Russian markets.

Contact to KITECH:

JIANGSU KITECH MACHINERY CO., LTD

Mobile/hatsApp: +86-17372583523

Add:No.7 Jiulong industry park Jinfeng Town Zhangjiagang Jiangsu China, 215628

Contact to KITECH:

KITECH MACHINERY CO.,

Tel:+86-512 58620105

Fax:+86-512 58620107

Mobile/hatsApp: +86-17372583523

Add:No.18 Yuefeng Road, Nanfeng Town, Zhangjiagang City Jiangsu, China, 215628