2015 /ISO CE Standard /High Quality PVC Plastic Twin-Wall Hollow Roofing Sheet ...

Qingdao Weier Plastic Machinery Co., Ltd.- Type:Sheet Extruder

- Plastic Processed:PVC

- Product Type:Extrusion Molding Machine

- Feeding Mode:One Feed

- Assembly Structure:Separate Type Extruder

- Screw:Twin-Screw

Base Info

- Model NO.:SJSZ 80,156

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Don′t Exhaust

- Automation:Automatic

- Computerized:PLC Control

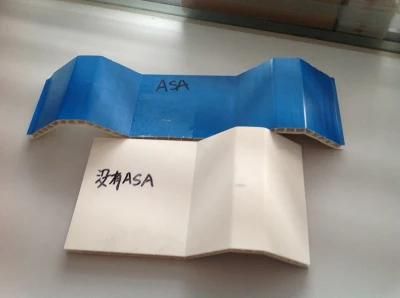

- PVC Roof Tile Structure:Round,Trapezoidal with Twin Wall

- Capacity:350kg,Hr

- Material:PVC or PVC+PMMA+Additives

- Machine Name:PVC Hollow Roof Sheet Line

- Power Supply:380V 3phase 50Hz

- Power:90kw

- Dimension:17000X2500X2200mm

- Weight:10t

- Electric Part Warranty:6monthes

- Machine Warranty:12monthes

- Transport Package:PE Elastic Film or Wooden Case

- Specification:As per customer′s request

- Trademark:WEIER

- Origin:Shandong Province, China

- HS Code:84774020

- Production Capacity:100sets,Year

Description

12~14mm Competitive Advantage: This 2015 new PVC Hollow Roof Sheet Forming Machine consists of extruders, extrusion mould, calibration system, haul-off machine, cutter and stacker. The extrusion mould adopts the latest co-extrusion technology with very precise design with multi-cavities. The shaping mould includes the vacuum calibrating system and special design of cooling runner with excellent cooling effect.