1000kg PE Scraps Washing PP Hard Cleaning PP Drums PP Bottles Washing Plastic Recycling ...

Jiangsu Aceextech Machinery Co., Ltd.- After-sales Service:24 Hours on Line

- Warranty:12 Months

- Material Processed:Film

- Plastic Type:PE

- Screw:Double-Screw

- Automation:Automation

Base Info

- Model NO.:ACW

- Computerized:Computerized

- Certification:ISO9001:2008, CE

- Controller:Siemens PLC

- Motor Brand:Siemens, Weg, Sew

- Inverter:ABB,Schneider,Siemens

- Bearing:SKF, NSK

- Output Capacity:500-1000kg,H

- Suitable Material:Post Consumer Film, Agricultural Film, Woven Bag

- Transport Package:Wooden Pallets

- Specification:ACW500

- Trademark:KITECH

- Origin:China

- HS Code:84778000

- Production Capacity:10-30 Sets, Year

Description

Basic Info.

Model NO. ACW Computerized Computerized Certification ISO9001:2008, CE Controller Siemens PLC Motor Brand Siemens, Weg, Sew Inverter ABB/Schneider/Siemens Bearing SKF, NSK Output Capacity 500-1000kg/H Suitable Material Post Consumer Film, Agricultural Film, Woven Bag Transport Package Wooden Pallets Specification ACW500 Trademark KITECH Origin China HS Code 84778000 Production Capacity 10-30 Sets/ YearProduct Description

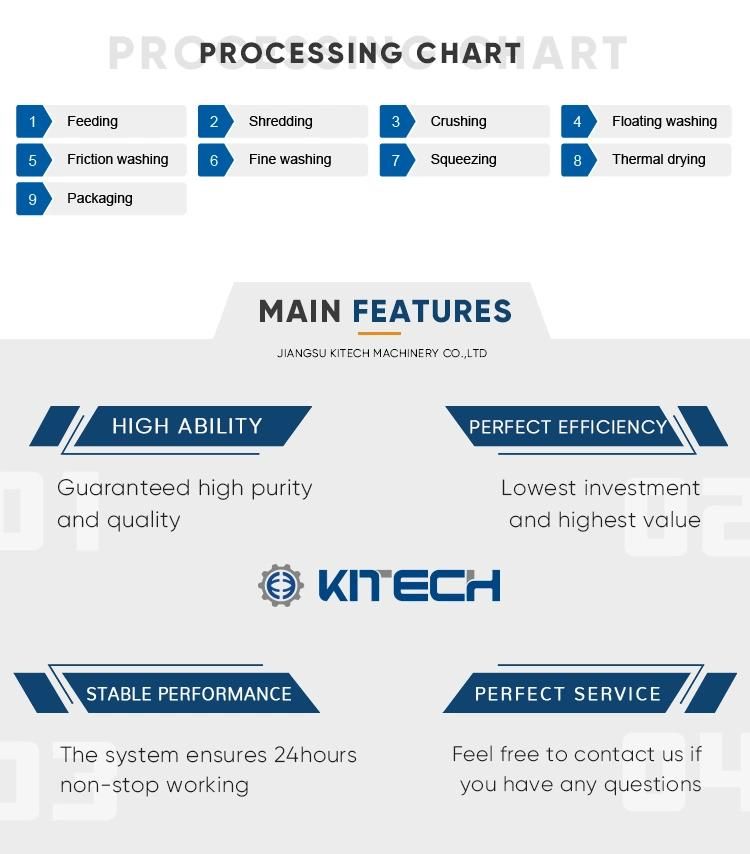

1000kg PE Scraps washing PP Hard cleaning PP Drums PP Bottles washing Plastic recycling machines.>>Soft Plastic (Film/woven bag/fiber/rope) Washing Line has smart modular design aiming at agricultural film, industrial packaging film, bag, blowing molding packaging bottle/box, injection and electronic waste recycling. It is including sorting, size reduction, metal removing, cold and hot washing, high efficiency friction washing and drying modular. Which can remove most of contaminants such as ferrous and nonferrous metals, sand, oil, glue, paper label and many other different contaminants efficiently. Moreover, turn key solution can be provided with all water treatment, processing of sludge, paper stick, labels and etc.

>>You can get a different module combinations designed by KITECH according to your requirements and material's condition. In range of capacity 300-2000kg/h with both economy and high-level different configurations.

1000kg PE Scraps washing PP Hard cleaning PP Drums PP Bottles washing Plastic recycling machines .

Recycling material of Plastic Recycling Washing Line:

1000kg PE Scraps washing PP Hard cleaning PP Drums PP Bottles washing Plastic recycling machines .

*Before-sale:

Introduce products professional

Project engineering

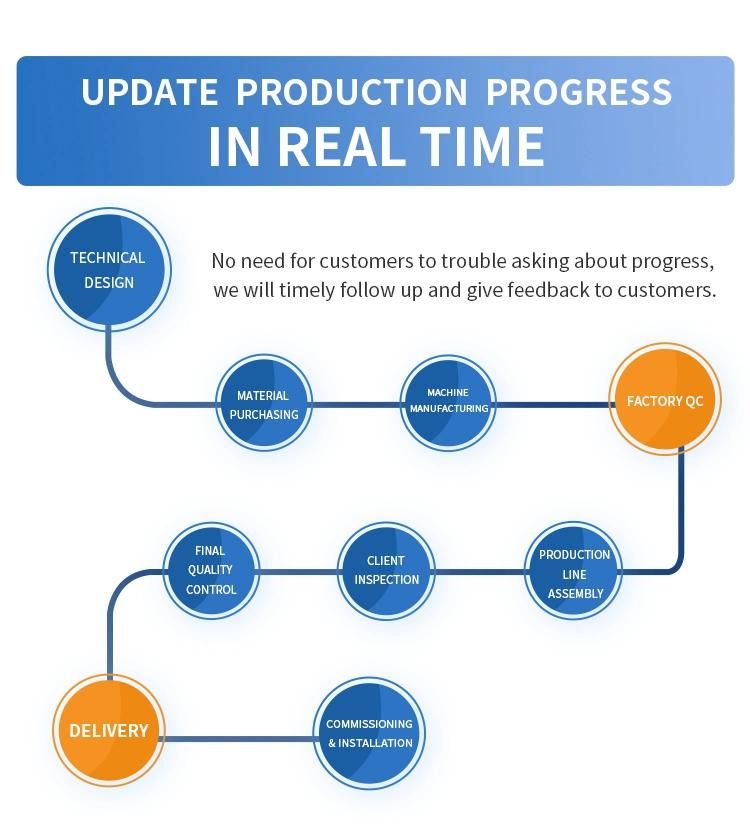

*During manufacturing:

Provide layout and engineering conditions

Inform the schedule of production

Make sure the product designed in accordance with technical document

Test machine before delivery

Provide photos before shipping

*After-sale:

Build customers database. All machines are traceable.

Overseas installation, commissioning and training are available

Speed up service and spare parts supply.

Visit customers and make quality trace periodically

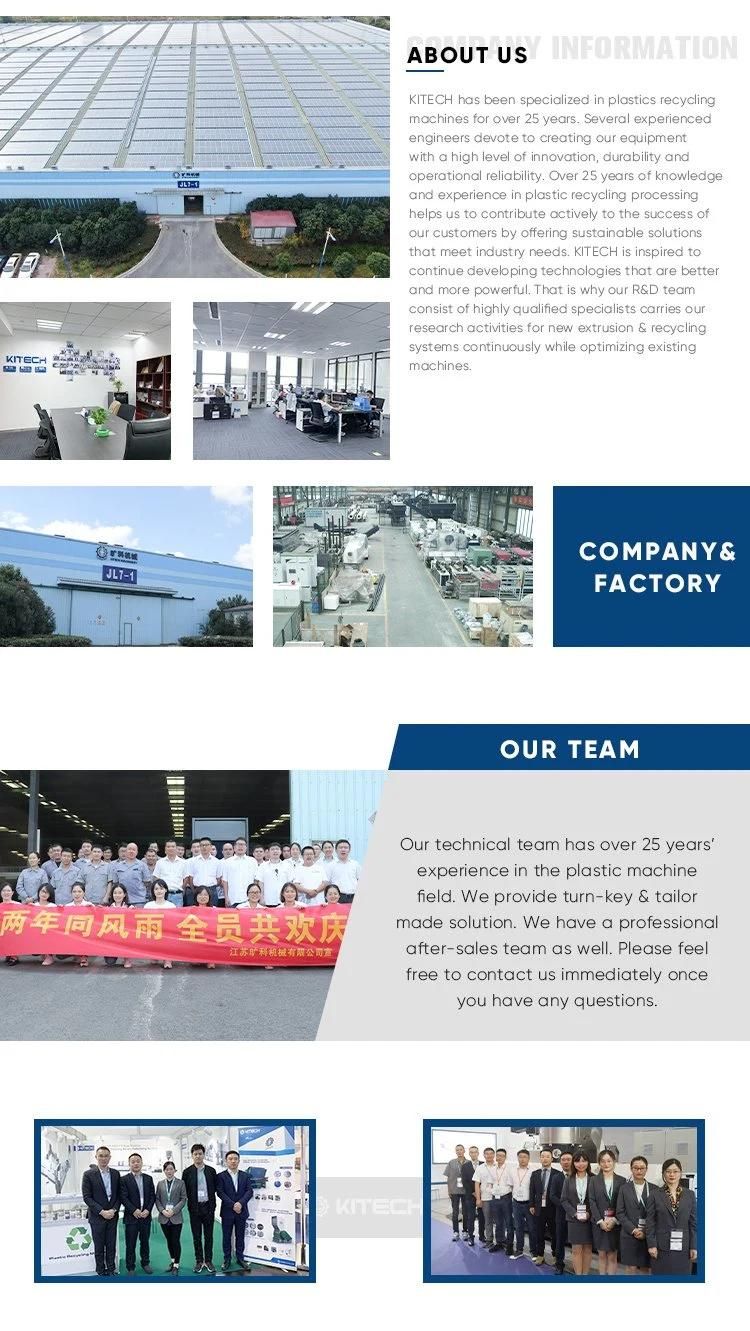

About KITECH:

Kitech is a creative company, focusing on R & D of plastic extrusion system, and providing the equipments and solutions for plastic pipe, profile, tile, sheet and board.

Kitech products fulfill the needs of users in a very direct way due to over 25 years of knowledge and experience in plastic extrusion field, which also helps us to contribute actively to the success of customers by offering sustainable solutions that meet industry needs.

Kitech offers a complete portfolio of support and consulting services all the time, from project engineering to custom financing solutions, after sales service at its best, ongoing production optimization, training and advisory services, even end product development.

Why KITECH:

- Specialized R & D team involved in plastic extrusion industries over 25years.

- Ability to provide the customized plastic extrusion solutions.

- Complete sales system covering the pre-sales, sales and after-sales service jobs.

- Professional sales team with local language speaking ability for English, Portuguese, Spanish, Turkish and Russian markets.

Contact to KITECH:

JIANGSU KITECH MACHINERY CO., LTD

Mobile/hatsApp: +86-17372583523

Add:No.7 Jiulong industry park Jinfeng Town Zhangjiagang Jiangsu China, 215628

Contact to KITECH:

KITECH MACHINERY CO.,

Add:No.18 Yuefeng Road, Nanfeng Town, Zhangjiagang City Jiangsu, China, 215628