Plastic Pet Bottle Washing Recycle Plant Pet Recycle Machine

Zhangjiagang Sevenstars Machinery Co., Ltd.- Material Processed:Plastic Bottle

- Plastic Type:PET

- Screw:Single-Screw

- Automation:Automation

- Computerized:Computerized

- Certification:UL, QS, GMP, ISO9001:2008, CE

Base Info

- Model NO.:BDX

- Motor:Siemens

- Color:Customer Choice

- Power Consumed:to Be Determine

- Final Flakes:14-16mm

- Transport Package:Seaworthy Packing

- Specification:CE ISO9001: 2008 SGS

- Trademark:BDX

- Origin:Jiangsu Zhangjiagang

- HS Code:84772010

- Production Capacity:500kg ,H or More

Description

Basic Info.

Model NO. BDX Motor Siemens Color Customer Choice Power Consumed to Be Determine Final Flakes 14-16mm Transport Package Seaworthy Packing Specification CE ISO9001: 2008 SGS Trademark BDX Origin Jiangsu Zhangjiagang HS Code 84772010 Production Capacity 500kg /H or MoreProduct Description

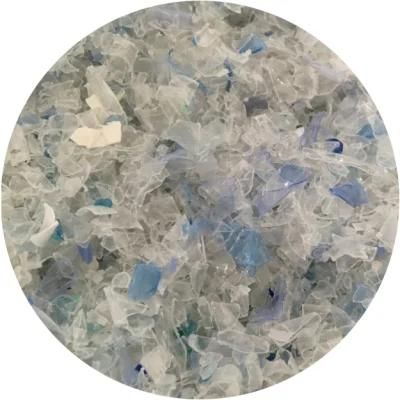

PET bottles washing recycling produce line-------from watse dirty bottles to clean pet flakes

Part A : Produce line overview

This produce line suit for all kinds of pet bottles, it adopt advance technology with high effect, high output,and highquality.

We have 14 years OEM/ODM experience for our pet washing recycling project, so we further refine the functions of the product line, and set a reasonable cleaning plan based on the conditions of your bottle.

We have high quality pet washing line,it is food grade,the final flakes washing by our machine can make bottles,food packing film,and other high quality plastics.

Part B : Machine details

Our produce line can clean 300, 500, 1000, 1500, 2000, 3000, 5000kg bottles per hour, here is the introduction of the main equipment.

1. Belt conveyor: Our belt conveyor main used to transport the bottles to the next station, the speed is adjustable by ABB inverter.

2. Tumble: it is for sorting sand, caps and the label, metal by low speed rolling.

3. Label remover: Removing the PVC label from bottles and collecting the labels.

4. Crusher: Our crusher adopt new design and crushing with water and force device to press the loose bottles and pre-washing.

5. Screw loader :This screw loader also adopt high speed and can washing the flakes and filter out the water wand impurity from

the bottom

6. High speed friction washer: washing the flakes by high speed friction, this is our main washing equipment.

-------------------------

7. Hot washer: washing with high temperature and chemical pharmacist to remove the oil and improve the quality of flakes

8. Float washer :washing the flakes by cool water and remove the residue chemical pharmacist

9. Dewater and drying machine: remove the water by high speed revolute and reduce the moisture by air drying.

10. Impurities separator: remove the impurities such as PVC, PP, PE, label, cap, metal etc.

11. Material color sorter: For high quality pet flakes to making food grade production, we set this kind of machine to get pure pet flakes without impurities.

12. Silo: Store the flakes and ready to packing.

13. Water treatment system: To clean the water and can recycle use for the produce line.

Part C : FLOW CHART

Our company can provide a wide range of standard and bespoke plastic crushing and washing systems to meet the ever changing and demanding requirements ofa modern recycling environment. The systems are capable of processing a wide range of plastic materials with varying levels of contamination including extremely heavy contamination, such as PET bottles and milk bottles/ PE bottles.The whole production line is easy to operate, efficient and low energy consumption.

Conveying PET bottle→lable remover→ manual sorting table →crusher→screw loader →Hot washer→screw loader→high speed friction washer→screw loader→floating washer→screw loader→spray washer → dewater machine → pipe line dryer → label separator → blower → hopper

Part D :Machine Album

---------------------------------------------------------------------------------------------------------------------

Part C : FAQ

FAQ---I don't know how to choose the equipment. | Is your product quality guaranteed?

what is the shipping date ......

We answer your questions one by one.

--------------------------------------------------------

1.You are factory or trade company?We are a production-oriented factory, almost all the machinery and produce line are self-produced.

We aren't trade company; we have manufacture experience for 14 years.2. How can I contact you?You can contact with me by Ali Baba trade manager, WhatsApp,WeChat,QQ,skype, also you can send me the information by mail.3.Wtaht is the delivery time (Especially during the epidemic)?Our factory has resumed production, there is no delay in delivery, all simple and single equipment will be shipped within 30 days,and all production lines will be shipped within 60 days4.If I do not have shipping agent, how to shipping the machine ?We have long-term cooperation shipping agent, you can choose CIF item for your goods, we will send it to the seaport you indicated.5.How to solve your equipment if there is a problem?The equipment technology is mature. Under normal circumstances, as long as it is operated properly, there will be no major problems. If the customer is unable to solve the problem, based on the timeliness, first communicate with our engineers through the network. If the communication still cannot be solved, we will send the engineer to your plant .6.If I buy your equipment, can I buy accessories for a long time?Our wearing parts are stocked to ensure that the production is not delayed.8.How to pay you the money?Our payment methods are T/T and letter of credit. Of course, we also encourage customers to conduct transactions through the Alibaba platform's letter insurance, which provides additional protection for the first-time buyers.9.What is your qualities guarantee.We have ISO and CE certification, and all the machine will be tested in our factory, when everything is OK, we will ship it, if there any problem, we will solve it before shipping.10. I want to know the approximate transaction stepsAt first, we will discuss the machine and send you the details of our machine.Then we have further discussing about the offer and finalized all the details of the machine.

Part D : Buying Guide

Buying guide---Our factory has a large number of product lines, which are very different

The following items can help you choose the machine or product suit for you.

--------------------------------

1.What is your material?

Our machine can adopt almost all the plastics,such as PP,PE,PVC,PET,ABS,EVA,different materials use different equipment.

2.What do you want to do?

Our machine can washing the material,can make granules,we also have crusher,shredder,grinder.

3.What is your output capacity?

We design equipment for different output,from 100kg/h to 5000kg/h.

4.What about the condition of your material.

Is your material totally new or waste material,it contains metal,sand,oil,and other impurities?

5.What is your budget?

We will customize the right equipment according to your budget.

6.Other information

Other information useful for us,you can provide it at the same time.

Thank you for your careful browsing

Please feel free to contact us for inquiry