Double Layer Rotary-Die Head PE Film Blowing Machine for T Shirt Bags with Flat Bags

RUIAN YUNBANG MACHINE CO., LTD.- Warranty:One Year

- Type:PE Film Blowing Machine

- Raw Material:PE

- Maximum Folding Width of Film:1200mm

- Screw Diameter:65mm

- Automation:Non-Automatic

Base Info

- Model NO.:sj45(50)-500-1700

- Computerized:Computerized

- Machine Weight:4T

- Certification:CE, ISO9001:2008, UL, QS, GMP

- Machine Name:Film Blowing Machine

- Output:30kg to 150kg

- Total Capacity:Around 15kw to 30kw

- Die Head:Two Die Head as Free

- Compressor:Including

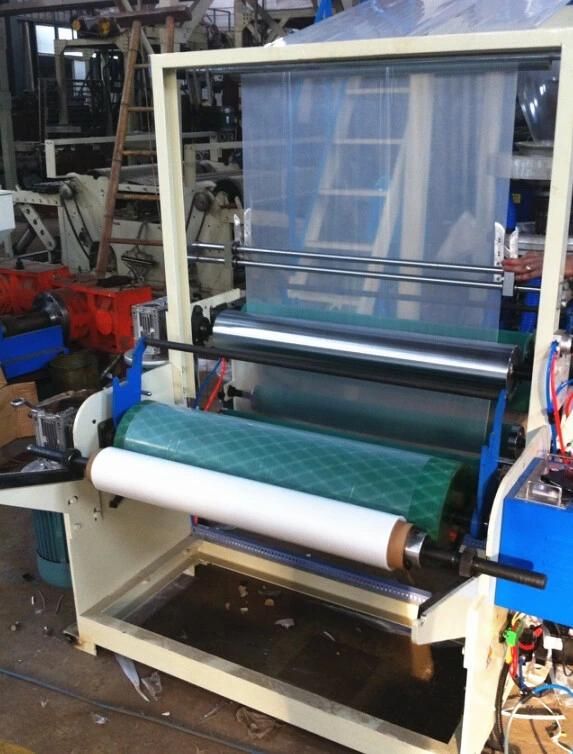

- Embossing Roller:Including

- Screw Material:Sacm645 or 38crmo Ala

- Transport Package:Wooden Case or Plastic Film Package

- Specification:CQC, ISO9001, CE, SGS

- Trademark:YUNBANG

- Origin:China

- HS Code:84773090

- Production Capacity:20sets

Description

Basic Info.

Model NO. sj45(50)-500-1700 Computerized Computerized Machine Weight 4T Certification CE, ISO9001:2008, UL, QS, GMP Machine Name Film Blowing Machine Output 30kg to 150kg Total Capacity Around 15kw to 30kw Die Head Two Die Head as Free Compressor Including Embossing Roller Including Screw Material Sacm645 or 38crmo Ala Transport Package Wooden Case or Plastic Film Package Specification CQC, ISO9001, CE, SGS Trademark YUNBANG Origin China HS Code 84773090 Production Capacity 20setsProduct Description

Product Description

Use:It is used for blowing the plastic laminated film of low density polyethylene (LDPE), high density polythylene(HDPE)and linear low density polyethylene(LLDPE)etc, Which are widely used for packing liquid, printed base material, products for export and industrial products, etc.

possible use:

HDPE: T-shirt bags, Garbage bag, Furniture cover film, Shopping bag

LDPE: Agriculture film, Construction cover, Dust cover, Pillow/mattress bag

possible products

Characteristics:

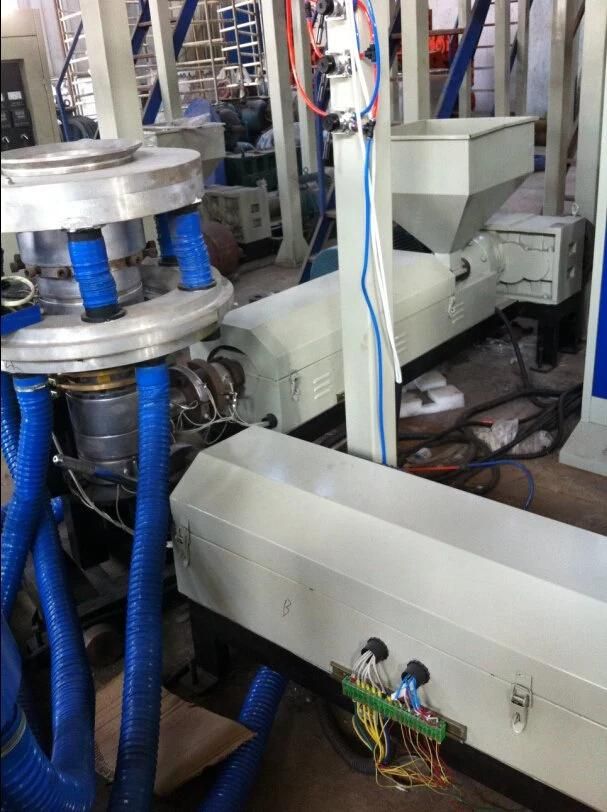

1. Double-layer co-extrusion laminated film can prolong the length for preservation of liquid package.

2. The cylinder and the screw stem of the extruder are made of high quality alloy steel with optimum hardness and durable service after precision finishing and nitrogen treatment.

3. The auxiliary machine has a platform working table for making operation easy and is equipped with bubble stabilizing ring.

4. Double-rolling and double-cutting coiling unit adopts torque motor to keep proper tensions and make rolling even and roll- changing easy.

| Model | SJ-50 | SJ-55 | SJ-60 |

| Diameter of screw | 50× 2 | 55× 2 | 60× 2 |

| L/D | 28: 1 | 28: 1 | 28: 1 |

| Reduced diameter of film(mm) | 800 | 1000 | 1200 |

| Single-face Thickness of film(mm) | 0.015-0.10 | 0.015-0.10 | 0.015-0.10 |

| Max. Output(kg/h) | 40 | 65 | 80 |

| Power of main motor(kw) | 11× 2 | 15× 2 | 18.5× 2 |

| Heating Power(kw) | 26 | 30 | 42 |

| Outline diameter(L× W× H)(mm) | 4200× 2200× 4000 | 4600× 2400× 4600 | 5000× 2800× 5000 |

| Weight(T) | 4 | 5 | 6 |

Die Head Part :

Take -Up Part :

Rewinding Part: