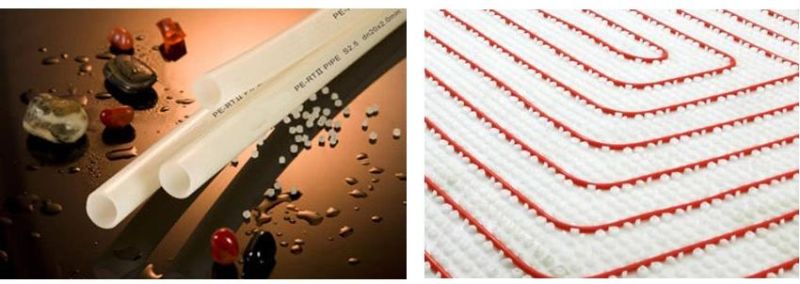

Floor Heating Pert Pipe Making Machine / Extruder Machine / Production Machine

Weifang Kaide Plastics Machinery Co., Ltd.- Product Type:PERT Pipe

- Screw No.:Single-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

- Customized:Customized

Base Info

- Model NO.:KDRT

- Condition:New

- Production Name:Pert Pipe Production Line

- Produced Pipe Diamater Range:16-32mm

- Production Speed:35m,Min; 60m,Min

- Extruder Type:Single Screw

- Control System:Simens PLC Controlled

- Trademark:KAIDEMAC

- Origin:Weifang, China

- HS Code:8477209000

- Production Capacity:200 Sets, Year

Description

1)High efficient five section type screw and barrel, to ensure fast plasticizing & dispersion effcct.

2)Gravimetric material feeding system is to control material feeding according to pipe parameter & line production speed, to get high qualified pipe with constant weight per meter. It's also have benefits of shortening start-up time, saving raw material and simplifying operation.

3)Spiral Pressure storage die head effectively overcomes the instantaneous fluctuation of extrusion pressure, realizing high speed pipe extrusion with stable pressure.

4)vacuum and calibrating system is further optimized based on our previous high speed pipe extrusion line technology; with better structure calibrating and cooling become more effective.

Automatic vacuum control system can adjust vacuum degree as per setting parameters on the main PLC.

5) for 50m/min speed model, equipped with fully automatic pipe coiler, with pipe accumulator. The accumulating will act while changing new coil, to storage pipe to prevent pipe gathered. And it will also work as an tension control, to automatically adjust the coiling speed.

The coiler will cut the pipe and change new coil automatically.

As an option, the auto strapping and unloading function can be added.

6) SIEMENS programable PLC control system with big color touch creen. Having multi-point close-loop control and sysnc system. Remote control system is also applied for after sales technology support.

Contact Us Right Now to Get Details!!