WPC Door Window Wall Pergola Fence Rail Chair Decking WPC Making Machine

Qingdao Tongsan Plastic Machinery Co., Ltd.- Type:Profile Extruder

- Plastic Processed:WPC

- Product Type:Extrusion Molding Machine

- Feeding Mode:One Feed

- Assembly Structure:Integral Type Extruder

- Screw:Twin-Screw

Base Info

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Don′t Exhaust

- Automation:Automatic

- Computerized:Computerized

- Plastic Material:PE,PP Recycled Plastic Material

- Wood Material:Wood Sawdust,Rice Husk,Straw,Cotton Straw

- Processing:Mixing, Granulating, Extrusion

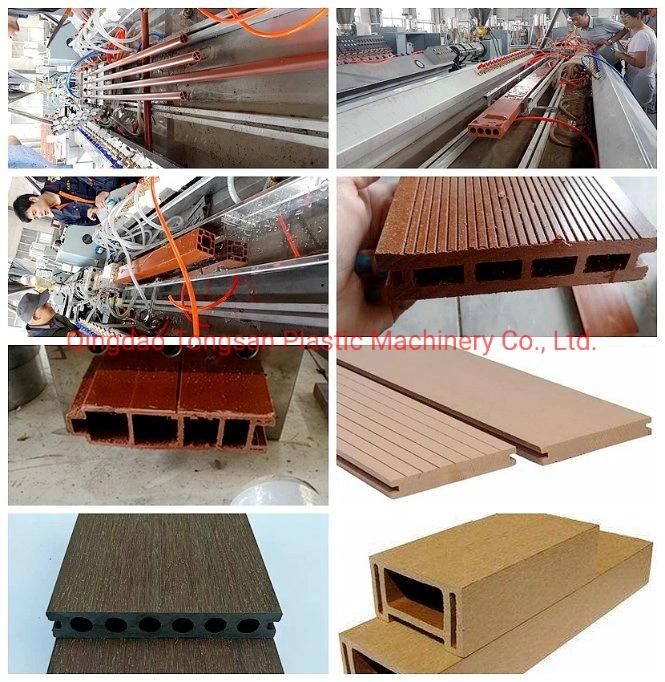

- Final Product:WPC Decking,Wall Panel,Post, Profiles

- Transport Package:Shipment Packing

- Specification:SJ65,132

- Trademark:TS

- Origin:China

- HS Code:8477209000

- Production Capacity:100sets,Year

Description

3. cost of wpc door window wall pergola fence rail chair decking wpc making machine

We have different WPC manufacturing plant according to customer's requirments

We have many WPC machine in stock for sale. fast delivery is avaliable

(24 hours running)

(24 hours running)

(24 hours running)

(24 hours running)

4. description of wpc door window wall pergola fence rail chair decking wpc making machine

HGMSE series PP/PE WPC profile production line can continuously produce PP/PE WPC profile.

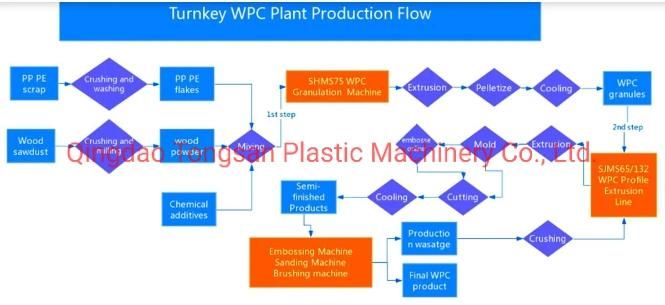

The WPC profile adopts two-step production process.The first step is using WPC granulating machine to make WPC pellets from recycled PP/PE material,wood powder and chemical additives.The max wood percentage can be 70%.The the WPC profile extrusion line will make the WPC pellets into WPC profiles by equip customized mold.We can equip on-line embossing machine to achieve 3D wooden pattern.

The profile produced by this production line can be sanded and brushed by sanding machine and brushing machine.

4.1 WPC mixing machine

Mixing wood and plastic and chemical additives

4.2 WPC granulation machine

After get ready wood powder and recycled PP/PE plastic, the first step is mixing them with chemicals, then use WPC granulation machine to make WPC granules

4.3. WPC profile extrusion line: extrusion and mold WPC profile products

The WPC profile extrusion line can make WPC granules into WPC products by equipping required mold, we can equip co-extrusion system and online 3D embossing device for making WPC products in high quality with wooden grain, the line also equipped with online cutting device.

4.4. Co-extrusion and online 3D embossing is good solution for making high quality WPC products

4.5. WPC product surface making machine

Embossing machine, sanding machine, brushing machine, online embossing machine

these machines is for making WPC products with better wooden feeling design.

5. WPC application

6. exhibition in domestic and abroad for recycled wood plastic composite wpc decking machine

many exhibitions are attended every year, such as Korea,Vietnam,Myanmar,Thailand,Malaysia, Bangladesh, India, Sri Lanka, Kazakhstan,Uzbekistan, Iran, Pakistan, Turkey, Algeria,Egypt,Ethiopia,South Africa,Mexico, America,Brazil, Columbia,Russia, Ukraine, Poland, Germany...

7. Abroad customer for recycled wood plastic composite wpc decking machine

we have 23 years experience for the corrugated pipe machine,our machine has been installed sucessfully all over the world: Turkey,Yemen,Malaysia,Ecuador,Benin,Mauritania,Uganda,Ukraine,Uzbekistan,Brazil,Bahrain,Pakistan,Qatar,Rwanda,Belarus,India,Indonesia,Congo,Dominican,Jordan,Sudan,Liberia,Saudi Arabia, Algeria,Argentina,Oman,Afganistan,Latvia,Kenya,Romania,Venezuela,Poland,Bangladesh,Bolivia,South Africa,Kazakhstan,Kuwait,Great Britain,Zambia, Morocoo,Mexico,Chile,Cote Dlvoire,Russia,Syria,America,Tunisia,Egypt,Thailand,Colombia,Peru,Philippines,Vietnam,Cameroon,Chile......