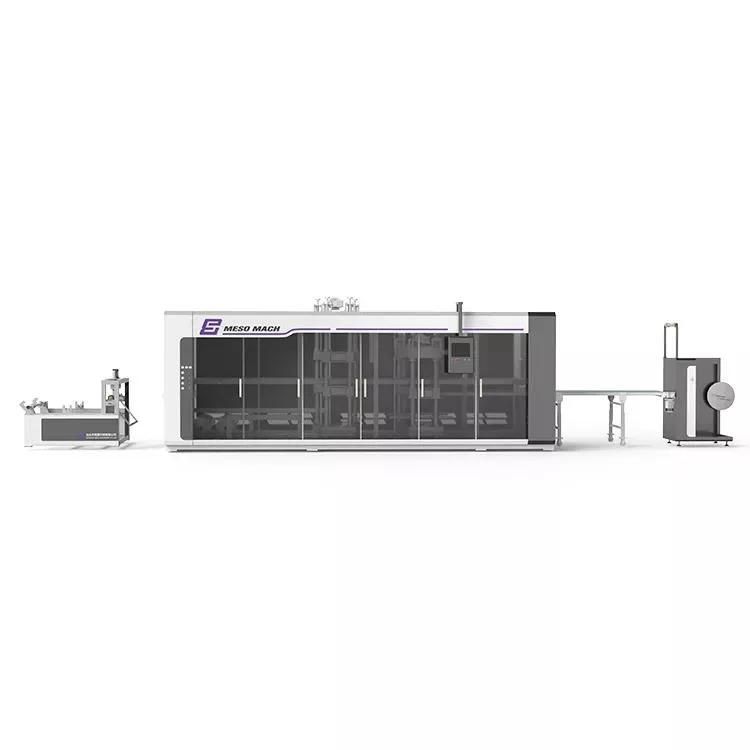

New Design Automatic Multi-Stations Thermoforming Machine Three Station Pressure & Vacuum ...

Shantou Feiteng Trading Co., Ltd.- After-sales Service:Training How to Install and Use The Machine

- Warranty:1 Year

- Certification:CE

- Molding Method:Plastic Thermoforming Machine

- Automatic Grade:Automatic

- Sheet Width(mm):350-760mm

Base Info

- Model NO.:MS720 three station forming machine-1

- Sheet Thickness(mm):0.2-1.5mm

- Core Components:PLC, Motor

- Sheet Roll Diameter:1200mm

- Forming Mold Distancen):up Mold 150,Down Mold 150

- Power Consumption:50-60kw,H

- Air Comsumption:1cube,Min.

- Max. Forming Area:720 X 600

- Mold Width:350-720

- Max Forming Depth:120

- Cutting Power:60ton

- Work Speed:Max 25

- Vacuum Pump:Universtarxd200

- Suitable Power:380V50Hz

- Total Power:188kw

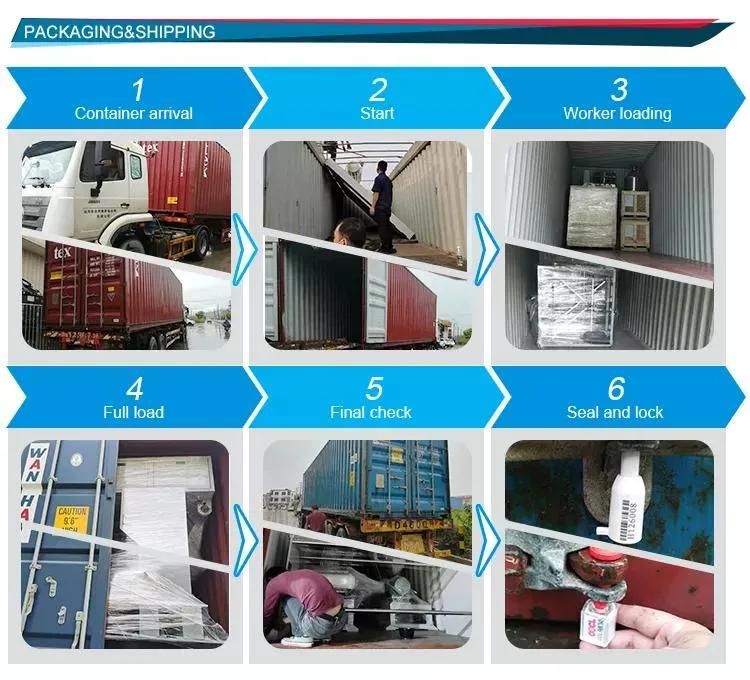

- Transport Package:Film and Wood Carton Packaging. by Truck,Ship

- Specification:12.5× 2.3× 2.8

- Trademark:OEM,ODM

- Origin:Guangdong, China

- HS Code:8477409000

- Production Capacity:100 Sets Per Year

Description

Basic Info.

Model NO. MS720 three station forming machine-1 Sheet Thickness(mm) 0.2-1.5mm Core Components PLC, Motor Sheet Roll Diameter 1200mm Forming Mold Distancen) up Mold 150,Down Mold 150 Power Consumption 50-60kw/H Air Comsumption 1cube/Min. Max. Forming Area 720 X 600 Mold Width 350-720 Max Forming Depth 120 Cutting Power 60ton Work Speed Max 25 Vacuum Pump Universtarxd200 Suitable Power 380V50Hz Total Power 188kw Transport Package Film and Wood Carton Packaging. by Truck/Ship Specification 12.5× 2.3× 2.8 Trademark OEM/ODM Origin Guangdong, China HS Code 8477409000 Production Capacity 100 Sets Per YearProduct Description

Equipment characteristics

1.Mechanical, pneumatic and electrical combination, all working actions are controlled by PLC. Touch screen makes the operation convenient and easy.

2.Pressure & Vacuum forming.

3.Five fulcrums with up mold and down mold forming type.

4.Servo streching.

5.Servo motor feeding, feeding length can be step-less adjusted. High speed and accurate.

6.Upper & lower heater, 4 sections heating

7.Heater with intellectual temperature control system, automatic supply the heating individual heater control. Fast heating,(save power about 15%)it won't be effected by outer voltage.

8.Forming,Punching,cutting unit mold open and close controlled by servo motor, products automatically count.

9.Stacking system: Downward stacking.

10.Memorization function can store running data.

11.Feeding chain width can be synchronously or independently adjusted in electrical way.

12. Heater have automatically push-out function.

13.Auto roll sheet loading, Quick mold change system, reduce the working load.