Pet Bottle Blow Molding Machine and Blowing Equipment

Shenzhen ES AQUA Machinery Co., Ltd.- Warranty:1 Year

- Type:Stretch Blow Molding Machine

- Raw Material:PET

- Making Method of Parison:Stretch Blow

- Automation:Automatic

- Computerized:Computerized

Base Info

- Model NO.:ESA-4-2000

- Certification:CE, ISO9001:2008

- Capacity:2000-6000bph

- Application:100-2000ml Bottle

- After Sale Service:Engineer Available Service Oversea

- PLC:Mistubishi

- Transport Package:Wooden Case

- Specification:20KW

- Trademark:ES AQUA

- Origin:Taizhou

- HS Code:847730200

- Production Capacity:500000,Year

Description

Basic Info.

Model NO. ESA-4-2000 Certification CE, ISO9001:2008 Capacity 2000-6000bph Application 100-2000ml Bottle After Sale Service Engineer Available Service Oversea PLC Mistubishi Transport Package Wooden Case Specification 20KW Trademark ES AQUA Origin Taizhou HS Code 847730200 Production Capacity 500000/YearProduct Description

Pet Bottle Blow Molding Machine and Blowing Equipment

| Condition: | New | Application: | Plastic Bottle | Plastic Processed: | PET//PP |

| Blow Moulding Type: | Stretch Blow Moulding | Automatic: | semi-automatic | Place of Origin: | Taizhou Zhejiang China (Mainland) |

| Brand Name: | ESAQUA | Model Number: | EA-4-2000 | Certification: | CE,ISO9001-2000, |

| Warranty: | one year | After-sales Service Provided: | Overseas engineer support available | Capacity | 3800BPH |

Specifications

Automatic blow moulding machine1)Germany components

2)BOTHFIT PLC

3)CE certificate

4)for 100ML-2000ml bottles

2021 hot sale automatic Blow Moulding Machine

What is Details of our products?

Brief introduction

Automatic blow moulding machine is suitable for producing bottles from 100ML-20L It is suitable for various PET/PP material and is widely be applied to produce bottle of mineral water, carbonated drink, beverage,juice,medicine, cosmetic,detergent ,oil bottles and lamp covers etc.

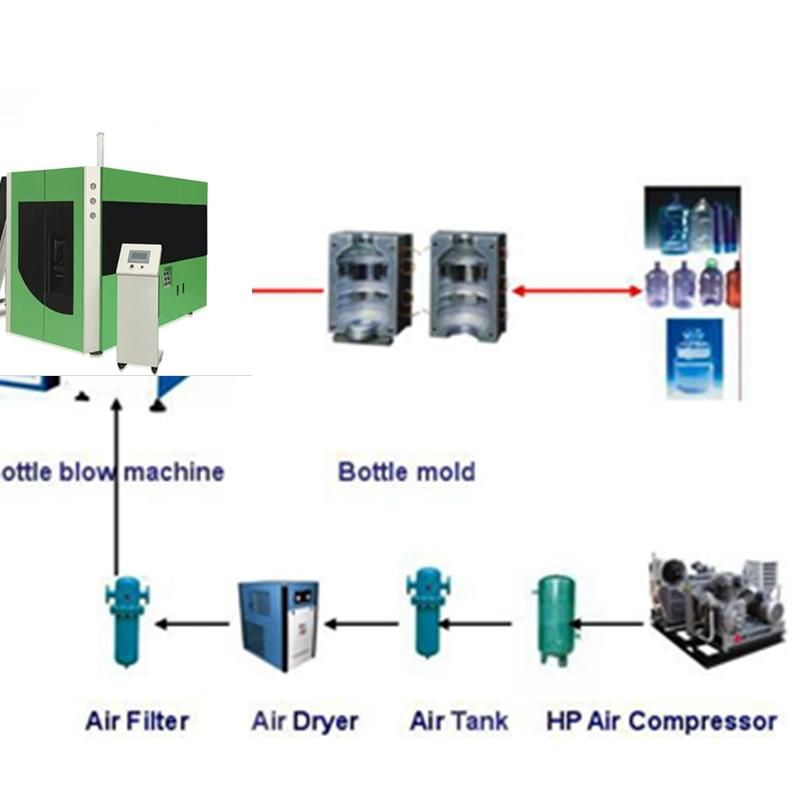

A complete production line of ES-A-2000 includes:

-Blower

-Infrared heater

-air filter(2pcs)

-High pressure air compressor(3.0Mpa)

- Blowing low-pressure Air Compressor(1.0)

-High-pressure air tank(0.6Mpa)

- Air Drier(3.0Mpa)

- Water Chiller(3 HP)

-Bottle mould(below/ 2L)

-Spare parts

Technical Parameter

| ITEM | ESA-4-2000 |

| Theoretical output | 3800 B/H |

| Max.container volume | 2L |

| Max.neck diameter | 45MM |

| Max.container diameter | 90MM |

| Max.container height | 325MM |

| Number of cavity | 2 |

| Number of lamp | 24 |

| Max.heating power | 50KW |

| Installation power | 110KW |

| Actual power consumption | 25KW |

| Operatating low pressure | 0.7-1.0Mpa |

| Low pressure consuming | 2000L/min |

| Blowing pressure | 2.5-3.5Mpa |

| High pressure consuming | 3500L/min |

| Operating pressure | 0.3-0.5Mpa |

| Temperatuer | 10 degree |

| Flow rater | 40 L/min |

| Machine dimension | 2.3×1.6×1.8 |

| Machine weight | 2200Kg |

Features

1.The machine adopts human-computer interface to control the whole working procedures, auto-loading, auto blowing, auto dropping. Action cylinders are all assembled with magnetic induction switches.Connect with PLC to control every step and test every cylinder. Next action will continue after the former step done, If former step is not finished, alarm automatically and do not work. PLC displays problem position.

2.Fast speed, accurate position, smooth action.

3.According to special demand, adopt cross double crank pressed clamping, with strong clamping force. Mould open stroke can be adjustable according to the bottle size to save the time.

4.Far infrared heater lamps have strong penetrations , preforms are heated uniformly while rotating, PLC or electronic pressure adjustor controls each group of temperature separately.

5.Particular pre-heater design makes preform close while heating. Change space, shorten heating tunnel and reduce energy consumption according to the bottle size while blowing.

6.The air supply system consists of slight blow, high pressure blow, low pressure actions, to supply enough air for different products.

7.Special recycling installation for high pressure air reduce the energy consumption.

8.Operation consists of manual and automatic procedure, manual operation for assembly and test, automatic operation for production.

9.Production workmanship process is fully automatic to make best quality and pollution-free. it holds less investment, high efficiency, easy operation, simple repair, safety etc.

About us

ES AQUA LTD is engaged in professionally researches, develops and manufactures beverage-packaging machinery and dairy packaging machinery. Since its foundation, ES AQUA has concentrated on a single area of beverage and water product packaging machinery.

We mainly produce good quality beverage production lines,injection machine molds,PET preforms,caps,labels.

We got the ISO9000 quality certification several years ago. Recently, we got the ISO9000:2000 quality certification. Good quality system makes our product quality at the high level.

Location:ZhangJiagang city,Jiangsu Province

Terms&Service

- Transaction terms:

The above quotation is based on FOB terms.

- Payment terms

30% as prepayment, and balance paid before shipment.

- Production time:

35 days since receipt of down payment.

- Installation instruction:

Video CD instruction movie and instruction book for installation and maintaining.

- Engineer provides:

On clients' requirement, our engineers can be sent to your factory for the installation and commissioning, but all traveling cost including return air tickets, accommodation etc and training fee (US$100.00 per person per day) in your country should be on your account. Our machines will be delivered to you in almost assembled condition.

- Warranty:

One year of guarantee from the date of delivery. If any parts have quality problem during the warranty period, we promise to send the relevant parts within 5 days to buyer by DHL or FEDEX courier.

- Online technology consultations