Keya73 Twin Screw Segment for Plastic Pellet Machine Extruder

Joiner Machinery Co., Ltd.- After-sales Service:24 Hours

- Warranty:6 Months

- Standard:DIN, GB

- Technics:CNC Machining

- Feature:High Quality

- Material:as Request

Base Info

- Model NO.:96,96

- Transport Package:Paper Box, Wooden Box

- Specification:as request

- Trademark:as request, JOINRE

- Origin:China

- Production Capacity:50000 Pieces,Pear

Description

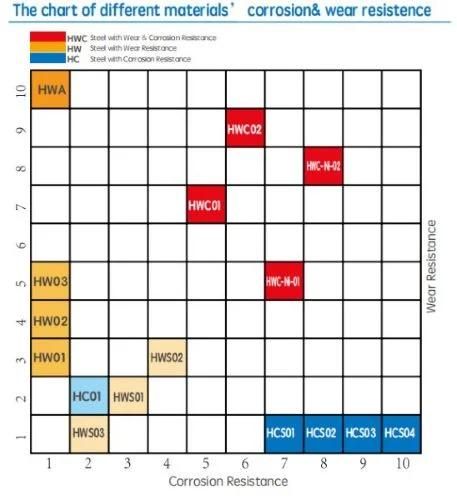

2. Wide choice of materials:

For wear application:

Tool steel: W6Mo5Cr4V2

PM-HIP materials: SAM10, SAM26, SAM39, CPM 10V,CPM9V.

For corrosion application:

Nitrided steel: 38CrMoAl

PM-HIP materials: WR4, SAM26, SAM39, CPM 10V,CPM9V.

For wear and corrosion application:

PM-HIP materials: SAM26, SAM39, CPM 10V,CPM9V

Other materials:

304, 316L, C276 etc.

Technics:

Heat treatment

Nitriding treatment

Hard-chrome electroplating

Bimetallic alloy welding

Bimetallic alloy centrifugal casting

3. Standerd Screw Element and Kneading Block

4. Standard production process

5. Heat treatment

As we all know, heat treatment is very important in the screw production process. In order to ensure the quality of products, Joiner has purchased professional heat treatment equipment to produce, so that we can control the construction process by ourselves. In China, we are the only company that does heat treatment by ourselves, and the heat treatment of screw components made by Nanjing factory is processed by outsiders, so the quality of products can not be completely guarantee.

6. Processing Route Tracking List

Each process requires inspection . The production personnel shall check whether it's meet the requirements of the drawings by themself. If it meets the requirements of the drawings,it shall be submitted to the inspection personnel for inspection. After pass the inspection to the next process personnel processing.

7. Quality Craftsmanship

We believe there's nothing more important than getting it right the first time! That's why our team of engineering experts does whatever it takes to design the best products to match your application. Once the design is complete, our shafts, barrels and screws are precision built to provide you with the highest level of quality and performance possible. Each product is then quality inspected for dimensional accuracy, straightness, and surface finishing.

8. Packing Details: According to your order quantities and products sizes to choose wooden boxes or cartons to pack:

- Rust-proof oil processing,

- Oiled paper packages,

- Bubble wrap package,

- Special foam packaging,

- Packing,

- Sealing.

9. Products photo: