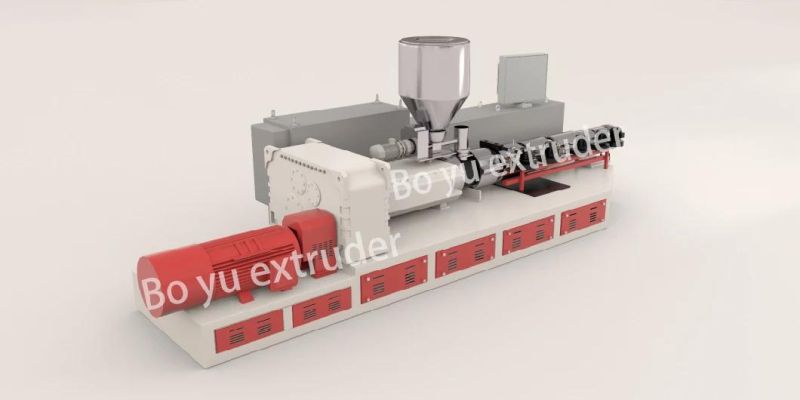

Spc (Stone Plastic Composite) Flooring Board Making Machine

Wuxi Boyu Plastic Machinery Co., Ltd.- After-sales Service:Installation, Debugging, Straff Trainnning

- Warranty:One Year (Except The Wear Parts)

- Type:Sheet Extruder

- Plastic Processed:PVC

- Product Type:Extrusion Molding Machine

- Feeding Mode:One Feed

Base Info

- Model NO.:SZJZ110

- Assembly Structure:Separate Type Extruder

- Screw:Twin-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- High Tech:PLC Control System

- Transport Package:PVC Film

- Specification:50m

- Trademark:BOYU

- Origin:China

- HS Code:8477209000

- Production Capacity:20 Lines,Month

Description

Basic Info.

Model NO. SZJZ110 Assembly Structure Separate Type Extruder Screw Twin-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized High Tech PLC Control System Transport Package PVC Film Specification 50m Trademark BOYU Origin China HS Code 8477209000 Production Capacity 20 Lines/MonthProduct Description

SPC flooring stands for Stone Plastic Composite. It is the newest generation of high-quality resilient flooring. SPC flooring is an upgrade of Luxury Vinyl Tiles (LVT). No matter laying them on concrete, ceramic or existing flooring. It has a unique interlocking-edge design (advanced "click" system) for easy installation.

The main component is lime stone (calcium carbonate)+ PVC Powder + Stabilizer. Different from regular vinyl floor, there is no plasticizer inside, so it is more environmentally friendly. SPC flooring mainly structured with the UV Coating, wear resistant layer, decorative film and core board. Meanwhile IXPE option available for high end usage.

1.Design parameters

| No. | Items | Data |

| 01 | Operation Conditions | 380V/3 phases/50Hz, DC24V. |

| 02 | Raw Material | PVC powder, calcium carbonate, stabilizer, lubricant, small materials |

| 03 | Main material proportion | PVC: CACO3= 1:3 |

| 04 | Product specifications | Width:1050/1350mm, Thickness:1-9mm |

| 05 | Machine Fabrication Certificate | CE |

| 06 | Electric components certificate | CE |

2.Equipment List

Extruder → T-die → Calender → Oil temperature controller → Traction machine → Cutting machine → Automatic flipper & Stacker

3.Extruder model

| Extruder model | Capacity/24h | Capacity/h | 4mm Linear Speed |

| SZJZ-80 | 6-8T | 250-350KG | 0.4-0.6m/min |

| SZJZ-92 | 12-18T | 500-700KG | 0.8-1.3m/min |

| SZJZ-110 | 25-32T | 1000-1350KG | 1.8-2.4m/min |

| SZJZ-180 | 70-100T | 3000-4000KG | 5-9m/min |

4.Finished board

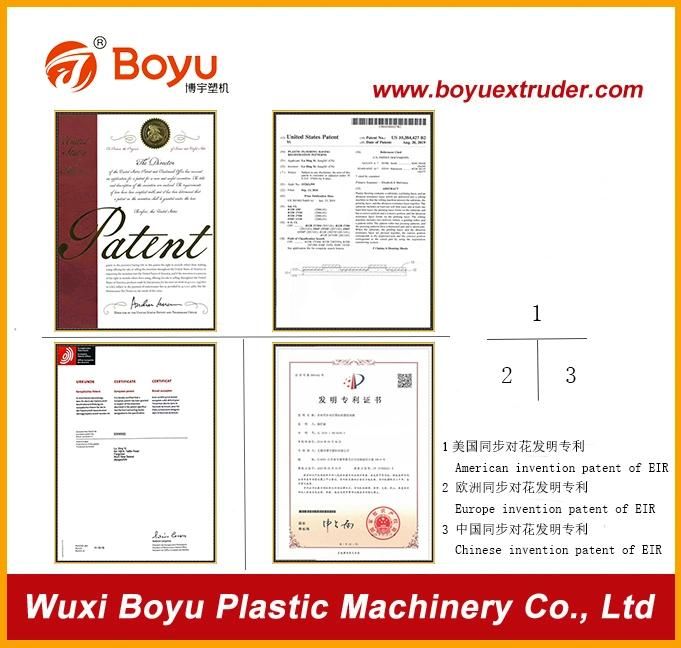

5.EIR Patent

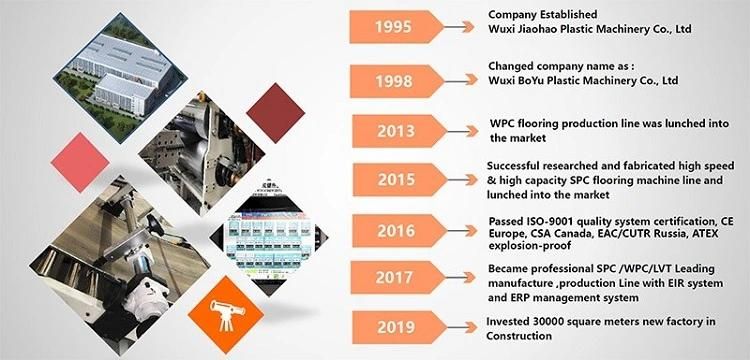

6.Boyu Development

7.Our Services:

1. Pre-sale service:

To provide market research information and consultation;

To provide all kinds of convenience and market service;

To help customers make project planning and systematic analysis;

To maximize customer's satisfaction.

2. After-sale service:

To install products and test products for customers;

To provide the formulas and technologies of relevant products and the information of chemical materials manufacture;

To provide technical direction according to customers' requirements;

To provide technical training for clients' employees;

To be responsible for maintenance service, door-to-door service under necessary circumstance.

3. Technology Support

Provide different products for formula and material supplier.

Production technology&Technical guidance.

Technicians dispatching for Guidance and technology exchange.

8.Shipping