16mm-63mm Double-out Type PVC Conduit Pipe Making Machine

Zhangjiagang Yusheng Machinery Co., Ltd.- Product Type:PVC Pipe

- Screw No.:Double-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

- Customized:Customized

Base Info

- Model NO.:YS63

- Condition:New

- Electrical Parts:Siemens

- Pipe Quantity:Double

- Pipe Diameter:16mm-63mm

- Color:Customized

- Guarantee Period:1 Year

- Manufacturing Time:40 Days

- Delivery:by Shipment

- Pack:by Film and Wooden Box

- Speed Control:by Inverter

- Speed:10-12m,Min

- Transport Package:Wooden Box

- Specification:16mm-63mm

- Trademark:Yusheng

- Origin:Zhangjiagang

- HS Code:84772090

- Production Capacity:250kg,H

Description

Basic Info.

Model NO. YS63 Condition New Electrical Parts Siemens Pipe Quantity Double Pipe Diameter 16mm-63mm Color Customized Guarantee Period 1 Year Manufacturing Time 40 Days Delivery by Shipment Pack by Film and Wooden Box Speed Control by Inverter Speed 10-12m/Min Transport Package Wooden Box Specification 16mm-63mm Trademark Yusheng Origin Zhangjiagang HS Code 84772090 Production Capacity 250kg/HProduct Description

Description of PVC electrical conduit pipe making machine:

PVC pipe extruder machine / PVC pipe making machine/PVC pipe extrusion line is mainly used in the manufacture of the UPVC and PVC pipes with various tube diameters and wall thickness such as the agricultural and constructional plumbing, water supply and drain etc.

This set is composed of conical twin-screw extrude, vacuum calibration tank, haul-off machine, cutter, stacker etc. The screw extruder and traction machine adopt imported AC frequency control device. The vacuum pump and traction motor both adopt advanced products. The haul-off machine has many models, such as two-claw, three-claw, four-claw, six-claw etc. It may choose visual blade or cutting type.The unit is of reliable performance and high production efficiency.

Characteristics of extrusion line for PVC electrical conduit:

1. one die double output, it greatly increase the productivity, meantime, it reduce the cost of machine, power consumption, save space of workshop

2. Speed of extruding, haul off are controlled by variable frequency inverter, stepless adjusting speed and save power consumption

3. Water cooling tank are made of high qulity stainless steel, no rusty, longer lifetime.

4. Temperature controlled by intelligent temperature controller, high precision, automatic control, save labor and easy to operate.

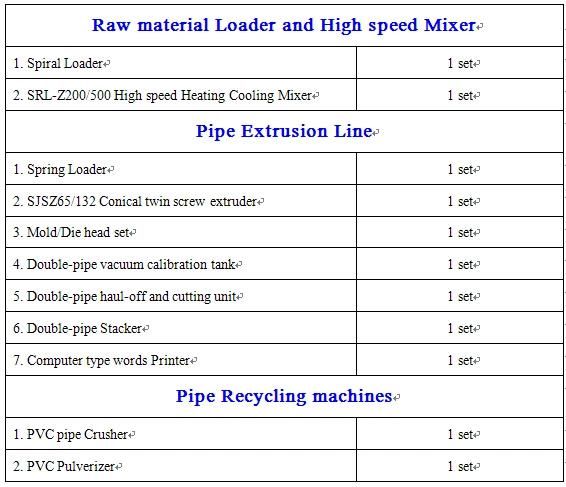

Machines condiguration: