Plastic PE/PP/PVC Single Double Wall Corrugated Pipe Extrusion Making Machine Production ...

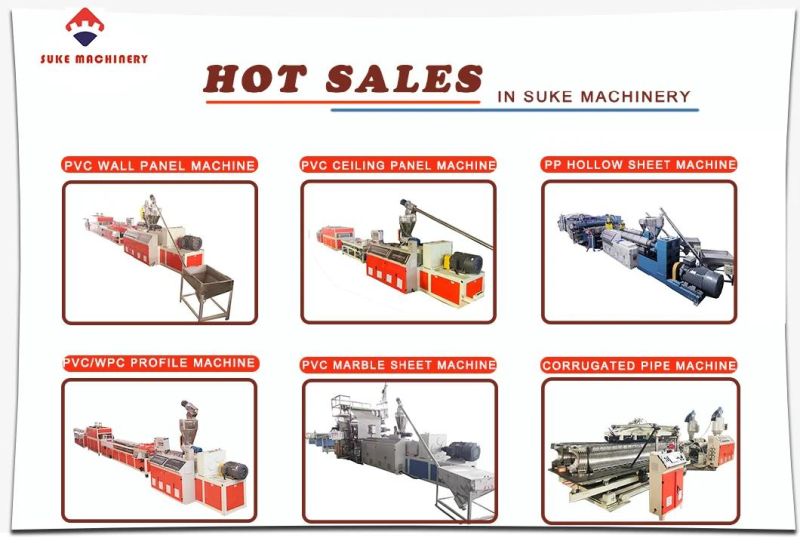

Qingdao Suke Machinery Co., Ltd.- Product Type:PE Pipe

- Screw No.:Single-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

- Customized:Customized

Base Info

- Model NO.:SJ65x30

- Condition:New

- Material:Stailness Steel

- Install Power:30kw

- Power Supply:380V, 50Hz or as Per Your Request

- Machine Name:PE Single Wall Corrugated Pipe Production Line

- Operator:2-3person ,Shift

- Line Speed:Max15m,Min

- Dimension:20mx2.3mx2.5m

- Capacity:100kg,Hr

- Machine Color:as Rquest

- Extruder Type:Single Screw Extruder

- Transport Package:PE Film and Wooden Package

- Specification:CE ISO9001

- Trademark:SUKE

- Origin:Qingdao, China

- HS Code:847780000

- Production Capacity:50sets,Year

Description

Basic Info.

Model NO. SJ65x30 Condition New Material Stailness Steel Install Power 30kw Power Supply 380V, 50Hz or as Per Your Request Machine Name PE Single Wall Corrugated Pipe Production Line Operator 2-3person /Shift Line Speed Max15m/Min Dimension 20mx2.3mx2.5m Capacity 100kg/Hr Machine Color as Rquest Extruder Type Single Screw Extruder Transport Package PE Film and Wooden Package Specification CE ISO9001 Trademark SUKE Origin Qingdao, China HS Code 847780000 Production Capacity 50sets/YearProduct Description

Plastic PE/PP/PVC Single Double Wall Corrugated Pipe Extrusion Making Machine Production Line

THIS LINE IS CONSIST OF:

1. Single Screw Extruder 1 set or 2 sets

2. Die Head 1 set

3. Molding Machine 1 set

4. Shaping Moldules 1 set

4. Twin Position Pipe Winder 1 set(as options)

5. Electrical Cabinet 1 set

APPLICATION:

Mainly used in wire and cable products threading pipe, washing machine drains, vacuum cleaner, ventilation pipes, tubes, etc.

MACHINE FEATURES:

1. Single Screw Extruder

1) L/D: 30/1

2) Screw and Barrel Material: 38 CrMoAlA

3) Surface Treatment of Screw and Barrel: Nitriding and Polishing

4) Barrel Heating Mode: Cast-Aluminium Heating Circles

5) Barrel Cooling Mode: Air-Blower

2. Gearbox Reducer

1) Type: Hardening Gear Surface, Low Noise

2) Gear Material: 20CrMoTi

3. Die Head/Mould

1) Specification: 8-50mm

2) Surface Treatment: Exact Grinding Processing After Forging with Die Steel

4. Molding Machine

1) Molding Module: 39 Pairs or More

2) Molding Module Material: 45# Stainless Steel, Through Exact Processing

3) Cooling Mode: Air-Blower

4) Speed Control: Japan Omron Frequency Inverter

5. Twin Position Pipe Winder

6. Electrical Cabinet

1) Main Electrical Components: ABB, Omron, Simens, RKC etc.

MACHINE DETAIL

| Modle | UNIT | JG-DBG90 |

| Raw Materoal | PE | |

| Extruder | Φ 90/25 | |

| Range of Pipe Dia. | mm | Φ 50-160 |

| Water Consumption | L/H | 4000 |

| Water Pressure | Mpa | 0.4-0.6 |

| Numble of Mould Block | Pair | 50 |

| Whole Length of Mould Block | mm | 5180 |

| Move Speed of Mould Block | m/min | 1-12 |

| Dimension (L × W × H) | m | 18× 1.35× 1.7 |

| Total Weight (Approx) | T | 6 |