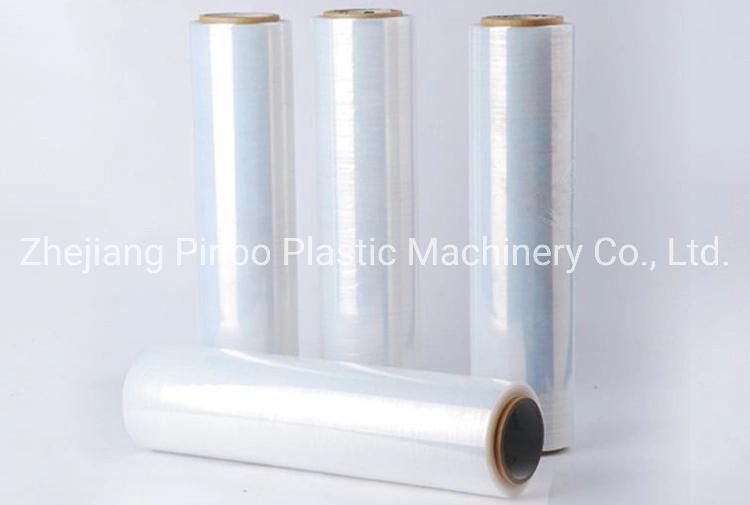

2/3 Layer Co-Extrusion Cast Line for Stretch Film

Zhejiang Pinbo Plastic Machinery Co., Ltd.- After-sales Service:Life Time

- Warranty:1 Year

- Type:Plastic Extruder

- Plastic Processed:LDPE,CPE,TPE,Pve,CPP

- Product Type:Stretch Film Machine

- Feeding Mode:Multiple Feed

Base Info

- Model NO.:PB-L55,75X1250

- Assembly Structure:Separate Type Extruder

- Screw:Twin-Screw

- Exhaust:Don′t Exhaust

- Automation:Automatic

- Computerized:Computerized

- Applied Material:LDPE, LLDPE, PVC, CPE, PEVA, CPP

- Vlotage:Customized

- Design Speed (Max):150m,Min

- Thickness:10-50 Micron

- Power(W):75kw

- Weight:8t

- Screw L/D:30:1

- Color:Can Be Customized

- Inverter:Delta, Taiwan

- Roll Exchange:by Auto Cut & Exchange

- Film Width:1000mm , 500mmx2 Rollers

- Package:Film Wrapping with Wooden Pallet

- Transport Package:Standard Packing

- Specification:7500*3000*3400mm

- Trademark:PYM

- Origin:Zhejiang Province Wenzhou City

- HS Code:84778000

- Production Capacity:200sets,Year

Description

Product Advantages

- Easy operating, long life, energy saving

- Stable and reasonable extrusion

- High quality T-die for excellent film evenness and stability

- Enhanced cooling system

(adopts 720 mm diameter primary cooling roller and 370 mm diameter secondary cooling roller) - Advanced oscillation (swing) system

- Highest winding speed (up to 200m/min) among similar stretch film machines

- High production capacity: up to 350 kgs/h at film thickness 23 microns and 150 m/min

- Optional System:

- vacuum pump

- Melting gear pump and PID controlling system

- Micro-computer temperature controller with touch screen for accuracy temperature control

- Automatic air shaft loading & off-loading to save man power

- Automatic screen changer with hydraulic station

Machine Details:

Extruder & T die

CONTROL BOX:

WASTE FILM CRUSHER: