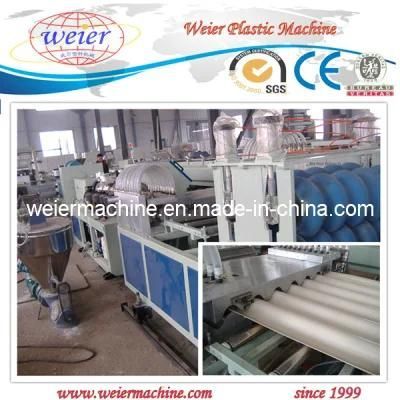

PVC Composite Resin Tile Production Line-Plastic Tile Machine (SJSZ80/156)

Qingdao Weier Plastic Machinery Co., Ltd.- Type:Sheet Extruder

- Plastic Processed:PVC

- Screw:Twin-Screw

- Automation:Automatic

- Computerized:Computerized

- Machine Name:PVC Roofing Sheet Making Machine

Base Info

- Model NO.:SJSZ80,156

- Capacity:400kg,Hr

- Line Speed:0.3-4m,Min

- Install Power:110kw

- Structure:ABA Ab a

- Air Consumption:0.3m3,Min

- Water Consumption:About3t,H

- Dimension:26000X3000X2800mm

- Operator:2-3person ,Shift

- Warranty:12monthes

- Transport Package:PE Elastic Film or Wooden Case

- Specification:As per customer′s request

- Trademark:Weier

- Origin:Shandong Province, China

- HS Code:84772090

- Production Capacity:100 Sets,Year

Description

Basic Info.

Model NO. SJSZ80/156 Capacity 400kg/Hr Line Speed 0.3-4m/Min Install Power 110kw Structure ABA Ab a Air Consumption 0.3m3/Min Water Consumption About3t/H Dimension 26000X3000X2800mm Operator 2-3person /Shift Warranty 12monthes Transport Package PE Elastic Film or Wooden Case Specification As per customer′s request Trademark Weier Origin Shandong Province, China HS Code 84772090 Production Capacity 100 Sets/YearProduct Description

Application of PVC roof tileThe corrugated PVC roofing sheets are weather-proof and provide protection against sun, rain, hail and snow. They transmit light softly and naturally. Additionally, they are non-conductive and non-inflammable. This kind of roofing sheets are available in various colors to meet architectural environmental or other needs. The filter sunlight softly create a bright and pleasant atmosphere. The smooth surface of these panels resists dirt accumulation, thus maintaining the panels visual appearance. Also the roofing sheets are liable and resist cracking, chipping and flaking. The extrusion machine is carefully made, easy to operate.

Why choose Weier?

1. We supply all the technical support, such as engineers, drawings, and instruction manual.

2. We send one or more than one engineers to client for installing and adjust all the machinery

3. Buyer also can sent workers to our workshop for learning how to conduct Plastic extruder

4. Supply formula guide service and staple raw material purchase.

5. We could supply the Feasibility Analysis Report for the project.

6. We could supply turnkey project to you.

| Item | Name | Qty |

| 1.1 | SJSZ80/156 conical twin screw extruder | One set |

| 1.2 | mold | One set |

| 1.3 | Pre-forming machine | One set |

| 1.4 | Forming machine | One set |

| 1.5 | Cooling bracket and edge trimming device | One set |

| 1.6 | haul off | One set |

| 1.7 | Cutting | One set |

| 1.8 | blanking | One set |

| 2.1 | SWP360 Crusher-11KW | One set |

| 2.2 | SHR200/500 mixer | One set |

| 2.3 | SMP500 pvc mill | One set |