Semi-Automatic 2000bph Bottle Blow Moulding Machine for Drinking Water Production

Zhangjiagang Proman Machine Co., Ltd.- Type:Stretch Blow Molding Machine

- Raw Material:PET

- Making Method of Parison:Stretch Blow

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, TUV

Base Info

- Model NO.:PM-SA4

- Suitable Bottle:Pet Bottle Size From 0.1-2L, 3-10L, 5 Gallon

- Function:Blowing Pet Bottles for Juice, Drinking Water, etc

- Material of Main Parts:SS304,316

- Mould Material:45# Steel

- Air System Contains:Air Compressor, Air Cooling Drier, Air Filter

- Cavity:1,2,4 Cavity

- Finished Product:Drinking Water Pet Bottle, Beverage Bottle

- Workers Needed:One Worker for One Blower

- Theoretical Output:See The Chart in The Detailed Description

- Markets:Global, Mainly in Africa, South East Asia

- Warranty:12 Months

- Transport Package:Export Standard Wooden Cases

- Specification:1900*1860*1930mm

- Trademark:Proman

- Origin:China

- HS Code:8477401000

- Production Capacity:1000sets,Year

Description

Basic Info.

Model NO. PM-SA4 Suitable Bottle Pet Bottle Size From 0.1-2L, 3-10L, 5 Gallon Function Blowing Pet Bottles for Juice, Drinking Water, etc Material of Main Parts SS304/316 Mould Material 45# Steel Air System Contains Air Compressor, Air Cooling Drier, Air Filter Cavity 1/2/4 Cavity Finished Product Drinking Water Pet Bottle, Beverage Bottle Workers Needed One Worker for One Blower Theoretical Output See The Chart in The Detailed Description Markets Global, Mainly in Africa, South East Asia Warranty 12 Months Transport Package Export Standard Wooden Cases Specification 1900*1860*1930mm Trademark Proman Origin China HS Code 8477401000 Production Capacity 1000sets/YearProduct Description

Semi-automatic 2000bph bottle blow moulding machine for drinking water production

Semi-automatic 2000bph bottle blow moulding machine for drinking water production adopts direct pressure, icrocomputer control, two step blowing bottle. The main blow tube blank PET mineral water bottles, beverage bottles, edible oil bottles, pharmaceutical plastic bottles, pesticide bottles, cosmetic bottles, etc.

Semi-automatic 2000bph bottle blow moulding machine for drinking water production adopts direct pressure, icrocomputer control, two step blowing bottle. The main blow tube blank PET mineral water bottles, beverage bottles, edible oil bottles, pharmaceutical plastic bottles, pesticide bottles, cosmetic bottles, etc.The gas path is designed to separate the gas and blowing, adopting low pressure(0.4-0.8Mpa) mould clamping, mould locking, sealing, stretching and high pressure(3-3.5Mpa) blowing form, and the gas-liquid locking structure, to not only ensure the clamping and locking action smoothly, also ensure the safety of mould and blowing quality, as a result can save the bottle perform material.

Technical parameters of Semi-automatic 2000bph bottle blow moulding machine

| Model | PM-SA4 |

| Number of cavities | 4 cavity |

| Material | PET/PC/PP/PE |

| Clamping force | 300KN |

| Max clamping stroke | 350mm |

| Bottom moving stroke | 60mm |

| Max. Stretching stroke | 380mm |

| Theoretical output | 2000BPH |

| Max. Area of mouldbase | 750*420 |

| Max. Mould thickness | 190mm |

| Space between tie bars | 670*340mm |

Auxiliary Machines

Air compressor Air cooling dryer Air filter

Characteristics of Semi-automatic 2000bph bottle blow moulding machine

· Adopting double crank to adjust mould ,heavy locking mould, stable and fast ,Adopt infrared oven to heat the perform ,the perform rotated and heated equally.

· The air system has been divided into two parts: pneumatic action part and bottle blow part to meet the different requirements for the action and blow .It can provide sufficient and steady high pressure for blowing large irregular shaped bottles.

· The machine is also equipped with muffler and oiling system to lubricate the mechanical part of the machine.

· The machine can be operated in the step-by-step mode and the semi-auto mode.

· The machine is small with low investment, easy and safe to operate.

A. Sample service

1. After you have paid the deposit, you can send us your bottle, we will help you debug the machine, test the sample, and will take the video and send it to you via email or WhatsApp.

2. Welcome to our factory to visit the operation of the machine.

B. After sales service

1. Installation: After the machine arrives at your company's factory, we will send engineers to install the machine and debug the machine.

2. Training: After the engineer has debugged the machine, he will help you train the company's employees and let them master the operation methods and normal maintenance of the machine.

3. Feedback: After the company has been running for a period of time, we will contact the customer for feedback and solve the problem.

4. Guarantee: Our company's machines are all provided with a one-year warranty.

5. Maintenance: We dispatch engineers to the factory for regular maintenance every once in a while to ensure the normal operation of the machine.

C. Customized service

We can design the machine according to the customer's requirements, do not change the existing machine structure, and customize the appropriate machine according to different requirements.

D.Packing Service

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

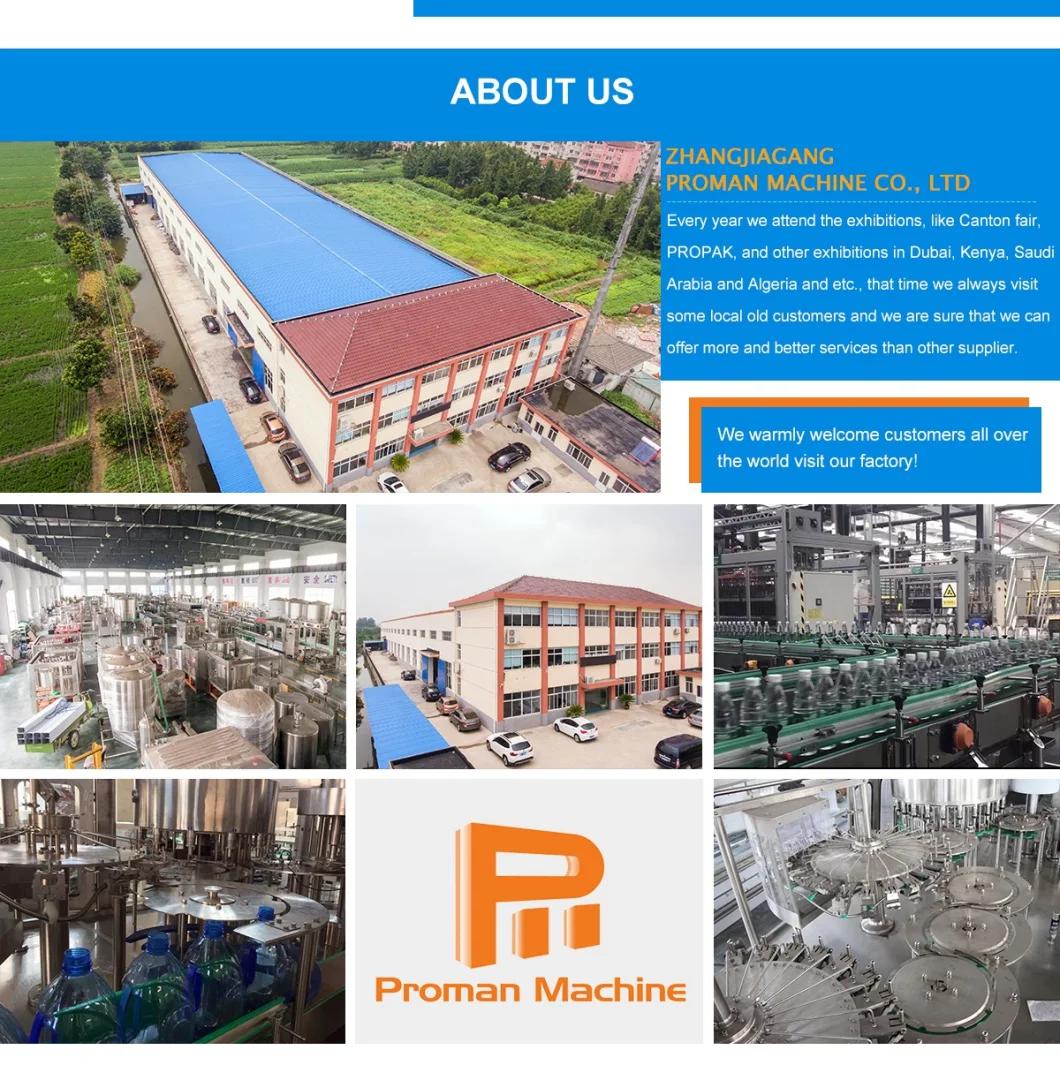

Zhangjiagang Proman Machine Co. Ltd,is a production manufacturer and exporter specialized in water treatment plants,beverage filling machine, packing machine, bottle blowing machine, injection moulding machine and spare parts of filling line.

Our factory was established in the year of 1998, with the long history of accumulated experience in filling machine industry in south Jiangsu. There are many development engineers of filling machine in our company. We devote ourselves to the development, research and production of liquid food and beverage packing and filling industry.

Besides, we have our own designs for the bottles.

Proman Machine cooperated with many customers in recent years, we win the trust of customers from our high-quality products. And we are looking forward to the future cooperation with you if our products can impress you deeply

FAQ

1. Where is your factory?

Our Factory is located in Zhangjiagang City, 2 hours drive from Shanghai and 1 hour drive from Wuxi(airplane & high-speed rail). If you arrive at Shanghai or Wuxi, we can pick you up to visit our factory.

2. Do you have any technical supports with your Beverage Filling Machines?

Yes, We have a professional team of engineers who owned many installation, debug and training experiences abroad, are available to service machinery overseas.

3. What's your guarantee or the warranty of the quality if we buy your machines?

We offer high quality machines with 1 year warranty and supply life-long technical support.

You're always welcome to visit our company. If you have any interest on our products. Please do not hesitate to contact us.