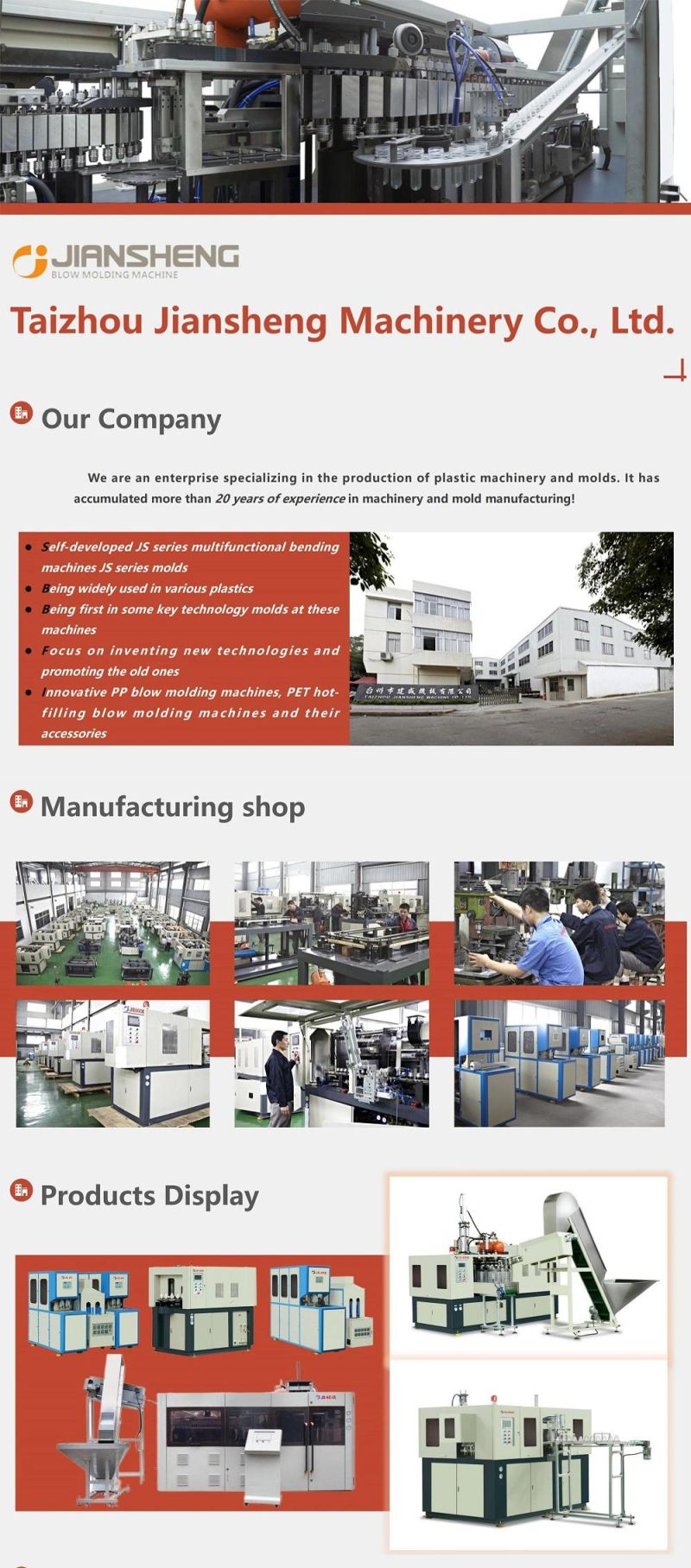

2 Cavities 10L Servo High Quality Blow Molding Machine

Taizhou Jiansheng Machine Co., Ltd.- Type:Stretch Blow Molding Machine

- Automatic Grade:Automatic

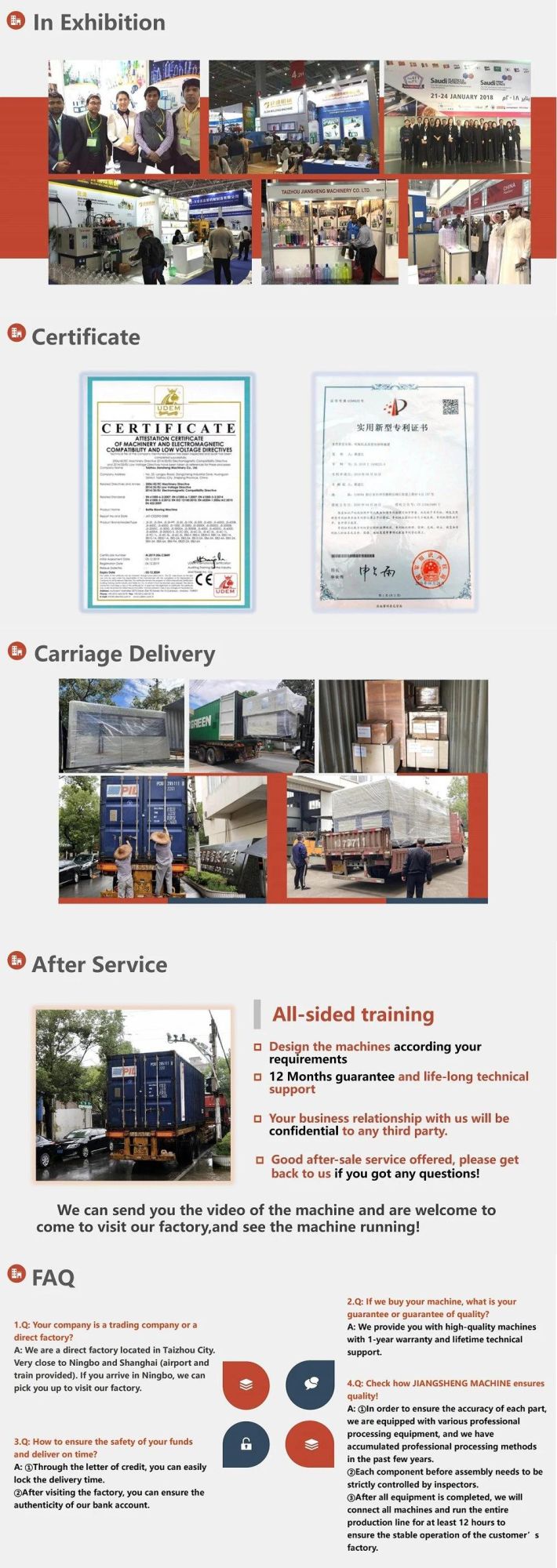

- Warranty:1 Year

- Number of Cavity:2

- Clamping Force:450kn

- Mould Opening Stroke:260mm

Base Info

- Model NO.:JS2000C

- Stretch Stroke:430mm

- Max. Neck Size:65mm

- Max. Bottle Diameter:210mm

- Max. Bottle Height:430mm

- Machine Size:2.8*2.25*2.4m

- Raw Material:Pet

- Making Method of Parison:Stretch Blow

- Automation:Automatic

- Computerized:Computerized

- Certification:CE

- Transport Package:Wooden Box

- Specification:SGS, CE

- Trademark:JS

- Origin:Huangyan, Taizhou, Zhejiang, Pr. China

- HS Code:84773090

- Production Capacity:1000-1200PCS,H

Description

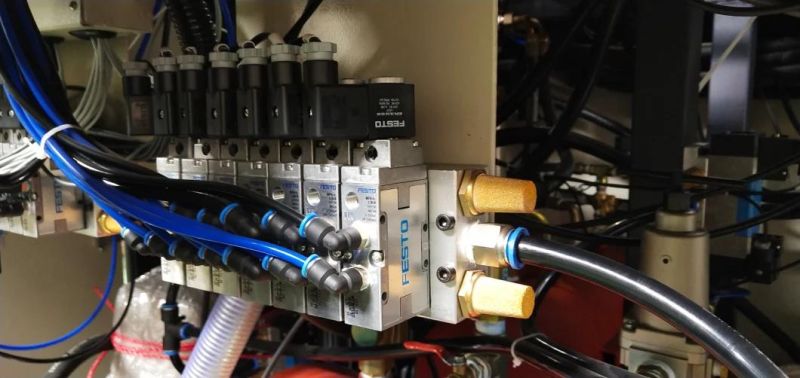

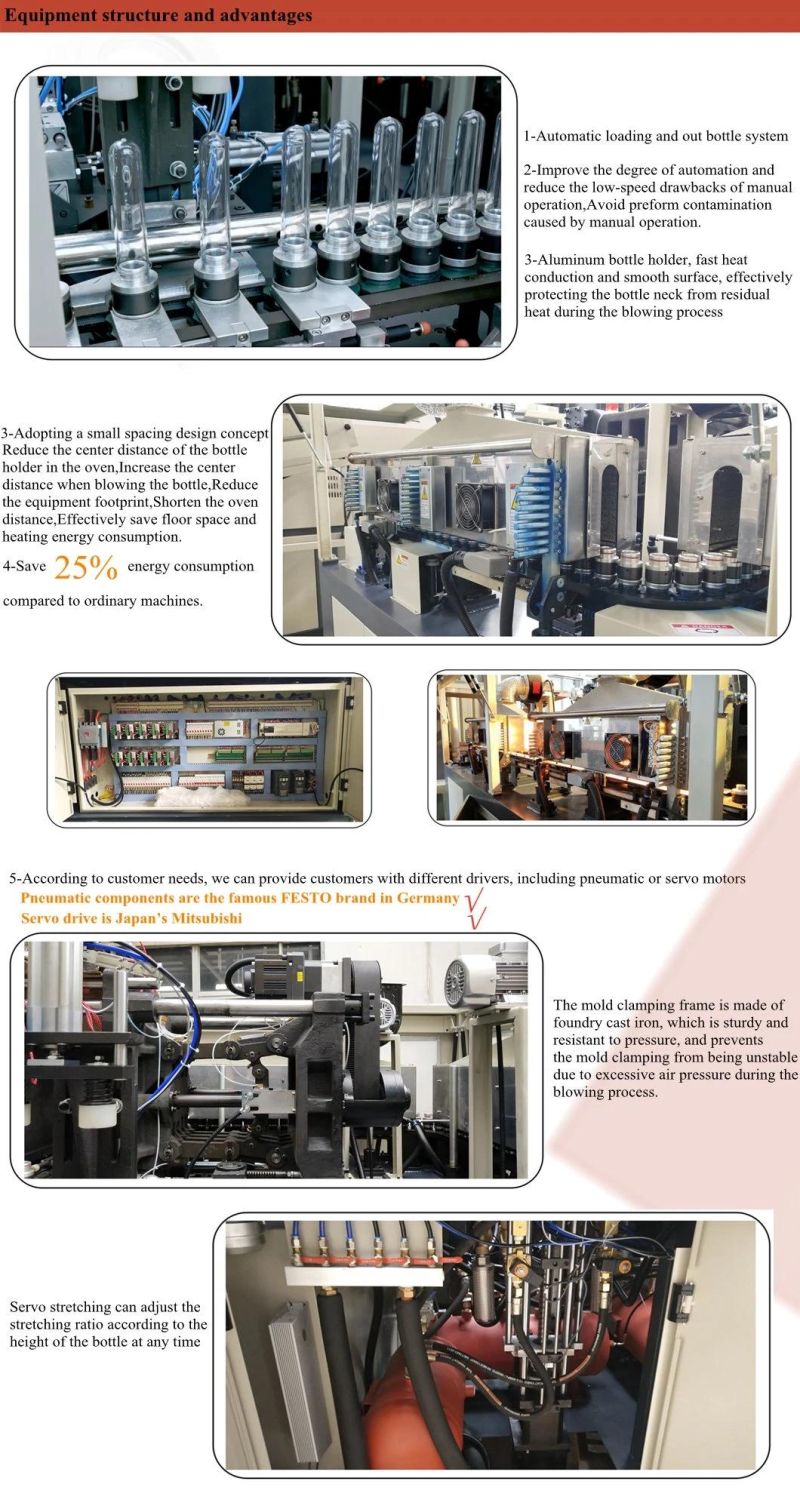

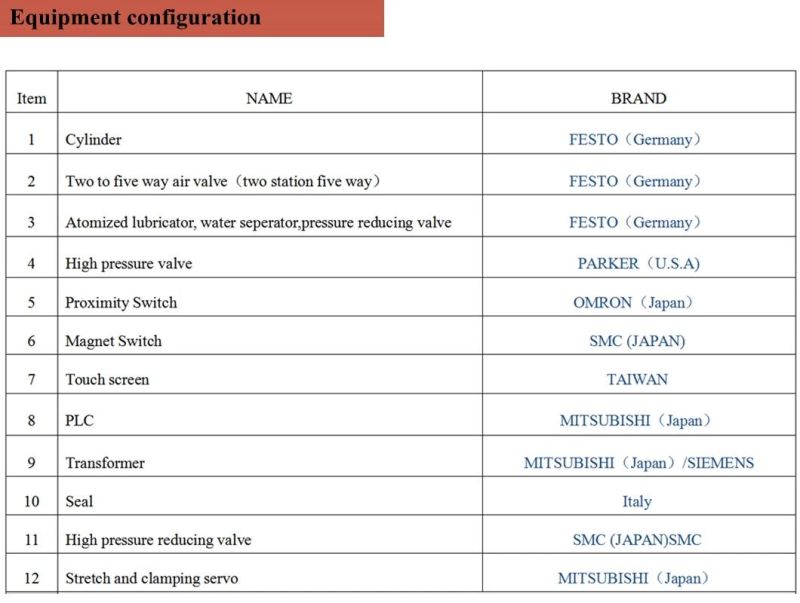

1.High quality compact machine Most popular pet bottle blowing machineJS-2000C With touch screen, Use Festo ( German brand) , SMC (Japan brand ) & Parker ( U.S.A Brand) pneumatic components. PLC use Mitsubishi (Japan brand)

2.Nontoxic conveyor belt to carry preforms

3.Produce PET Bottles ( such as: wine, beverage, soybean, vinegar bottles and so on)

4. Easy to maintain

5. Infrared lamps

6.High safety. high speed with high efficiency.

7.Manual saving, one man is enough for operation the machine.

8.Stable performing with easy maintaining.

9.Imported PLC controlling and man-machine interface computer.

10.Japan Omron inspection sensor.

11.Adopt the new type double bend arm and the four rod-clamping structure(won the patent): Cross direction; Middle mould board is move parallel; the distance between two mold board is adjusted by the chain wheel. Thus, the clamping force is very strong.

12.Power saving design that can increase your profits.

13.Segregate type air controlling system, which is designed for avoiding waste pollution.

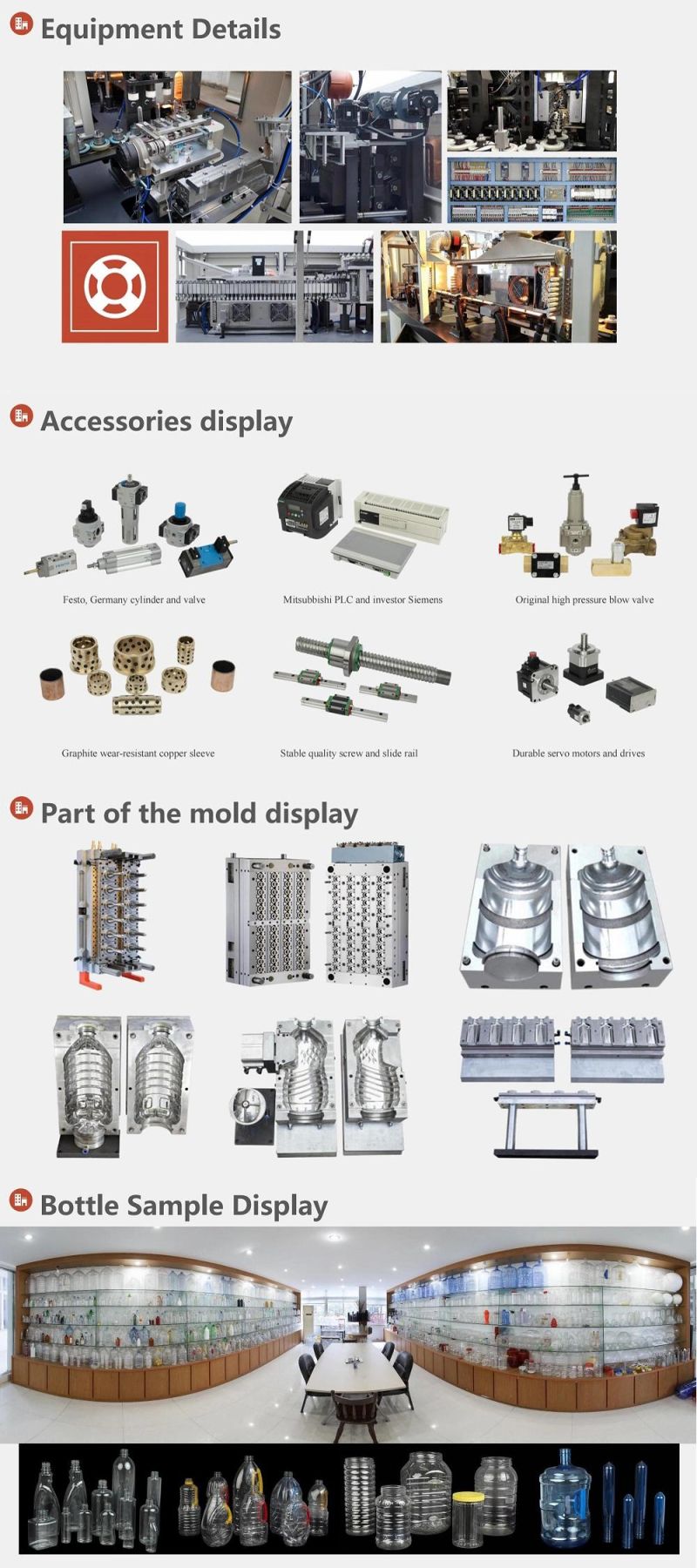

Internal details of the Machine