PVC/PP/PE/TPE Silicone Teflon Wire Stranding Rubber Mixing Mill Cable Automatic Feeder LED ...

Dongguan Dinglong Electrical Machinery Co., Ltd.- After-sales Service:The Warranty for Normal Use Is One Year, Excluding

- Warranty:The Warranty for Normal Use Is One Year, Excluding

- Type:Pipe Extruder

- Plastic Processed:FEP,Fpa,ETFE

- Product Type:Profile Extrusion Molding Machine

- Feeding Mode:Multiple Feed

Base Info

- Model NO.:DL

- Assembly Structure:Separate Type Extruder

- Screw:Single-Screw

- Engagement System:Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Finished Diameter:0.1-5.5mm

- Marketing Type:Ordinary Product

- Condition:New

- Voltage:380V, 50Hz, 3phase,Customized

- Color:Customized

- Feature:Fast Speed

- Certification:ISO 9001:2008

- Video Outgoing-Inspection:Provided

- Machinery Test Report:Provided

- Transport Package:Export Wooden Case

- Trademark:DL

- Origin:China

- Production Capacity:100 Sets,Year

Description

Basic Info.

Model NO. DL Assembly Structure Separate Type Extruder Screw Single-Screw Engagement System Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Finished Diameter 0.1-5.5mm Marketing Type Ordinary Product Condition New Voltage 380V, 50Hz, 3phase/Customized Color Customized Feature Fast Speed Certification ISO 9001:2008 Video Outgoing-Inspection Provided Machinery Test Report Provided Transport Package Export Wooden Case Trademark DL Origin China Production Capacity 100 Sets/YearProduct Description

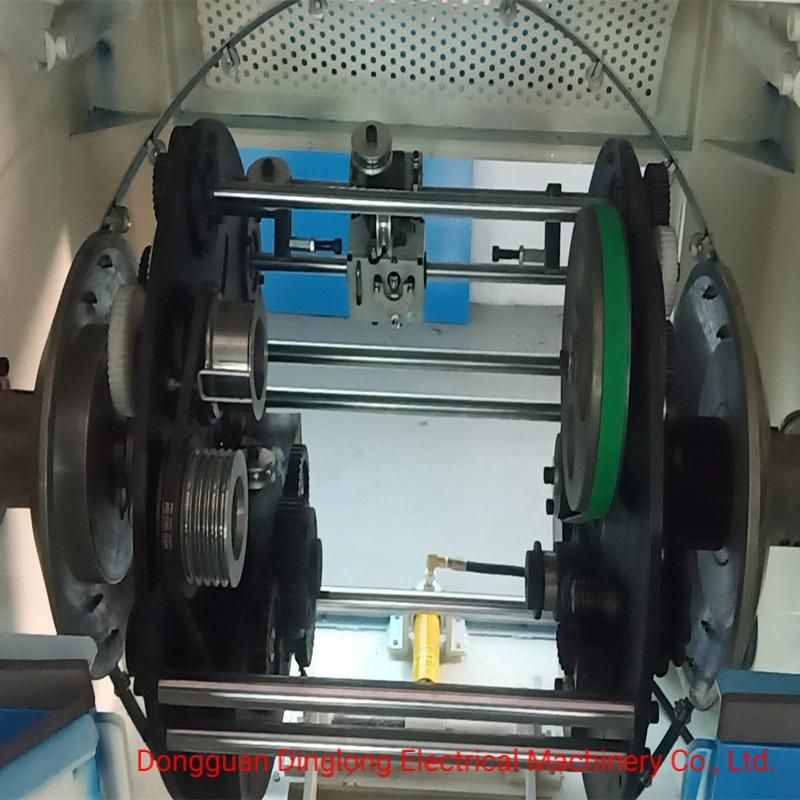

PVC/PP/PE/TPE Silicone Teflon Wire Stranding Machine Rubber Mixing Mill Cable Automatic Feeder Machine LED Lamp Strip Equipment Plastic MachineI Technical advantage (technology wins the market)

1, In 1997, we committed ourselves to the R & D and manufacturing of silica gel equipment and wire and cable equipment, with rich experience

2, Provide customers with solutions for various stages of silicone hose, wire, profile and cable production process, improve the equipment according to customers' products, and provide customers with the best equipment.

3, Provide customers with one-stop services such as plant planning, whole plant equipment investment planning, selection and allocation of developers and staff operation technology training.

4, New product development and certification technical support services. Our technicians are familiar with the production process of various silica gel products and national wire standards, the performance of various silica gel raw materials, and the development and certification of various electronic wires, silica gel wires, network wires, HDMI wires, power wires, Teflon wires, rubber wires and other products

5, With strong market share and good reputation, our company has gathered a large number of information about silica gel, cable materials and various conductors to provide good, most affordable and most convenient investment services.

II Team advantage (team building brand)

1, We have the most professional mechanical equipment design and R & D team in China to provide our customers with the most authoritative solutions to process difficulties and equipment shortcomings.

2, We have the most professional business team in the industry to provide our customers with the most considerate service, the most elaborate technical questions, the most comprehensive investment scheme, the most high-end silicone products and cable production technology.

3, We have the fastest service team in China, set up a 24-hour service hotline and stationed service teams all over the country to provide customers with timely and professional services.

4, We have the most stable production and manufacturing team in China to provide customers with punctual, high-quality and cost-effective mechanical equipment.

5, We have the largest industrial chain cooperative enterprise team in China, which can provide our customers with services other than equipment (rubber and conductor), and provide customers with free proofing and machine testing materials.

III Service advantage (service retention)

The company always attaches importance to customer requirements, has a strong sense of customer service, regularly provides customers with professional equipment maintenance services, has a perfect customer network, and can provide customers with fast localized personal services.

Application:

Apply to extruding teflon high temperature cable with material FEP,FPA,ETFE etc

Technical Specifications:

| Machine modle | DL-300 | DL-500 | DL-630 |

| Twisting section | 0.035-0.937M | 0.073-2.5M | 0.8-6.7M |

| Diameter of single wire | 0.05-0.28 | 0.08-0.45MM | 0.16-0.63MM |

| Max speed | 3000RPM | 3000RPM | 2000RPM |

| Power | 3.7KW | 5.5KW | 7.5KW |

| Gross weight | 30KG | 150KG | 550KG |

| DL45 | DL65 | DL80 | DL90 | |

| Finished hose diameter | 1.5-30mm | 1.5-30mm | 3.0-60mm | 5.0-80mm |

| Line speed (max.) | 30m/min | 30m/min | 30m/min | 30m/min |

| Extrusion output (max.) | 60kg/h | 70kg/h | 100kg/h | 150 kg/h |

| L/D | 12:1 | 12:1 | 12:1 | 12:1 |

| Extruder power | 7.5KW | 11KW | 22KW | 30KW |

| High temperature curing length | 0.5m-1.3m | 0.5m-1.3m | 0.8m-1.3m | 0.8m-1.3m |

| Horizontal curing length | 6-8m | 6-8m | 8-10m | 8-12m |

| Capstan power | 0.75KW | 0.75KW | 0.75KW | 0.75KW |

| DL65 | DL80 | DL90 | |

| Finished hose diameter | 1.2-8mm | 2.0-16mm | 5-30mm |

| Line speed (max.) | 150m/min | 150m/min | 150m/min |

| Extrusion output (max.) | 70kg/h | 150kg/h | 200kg/h |

| L/D | 12:1 | 12:1 | 12:1 |

| Extruder power | 11KW | 22KW | 30KW |

| Curing length | 16m | 24m | 24m |

| Payoff reel | PN400-630 | PN500-1000 | PN800-1250 |

| Capstan power | 2.2KW | 5.5KW | 7.5KW |

| Take-up reel | PN400-630 | PN500-1000 | PN800-1250 |

| DL65+45 | DL65+65 | DL80+65 | DL90+65 | |

| Finished diameter | 1.5-28MM | 1.5-30MM | 2.0-40MM | 3.0-60MM |

| Line speed | 10M/min | 10M/min | 10M/min | 10M/min |

| Extrusion output | 65Kg/h | 70Kg/h | 100Kg/h | 150Kg/h |

| Length diameter ratio of screw | 12:1 | 12:1 | 12:1 | 12:1 |

| Extruder power | 11KW | 11KW | 22KW | 22KW |

| Horizontal curing length | 20M | 20M | 20M | 24M |

| Capstan power | 1.5KW | 1.5KW | 1.5KW | 1.5KW |

FAQ1

Q1: How long is the delivery time?

A1: It will take 20 days from the beginning to the end of the production.

It takes more than 30 business days to customize complex mechanical equipment.

Q2: What is terms of payment? MOQ?

A2: T/T. 1 set.

Q3: How do you gurantee the machine stable operating?

A3: We do pre-shipment test for every single piece of machine.

We have seperate QC, delivery, sales and after-sales departments.

Also strict management process from pre-sales to after-sales.

Q4: How is your after-sales service?

A4: 1 year warranty with 60+ oversea after-service engineers

(oversea after-service team of high efficient, professional and enough experience for various non-standard project) .

Q5: How can I install my machine when it arrives?

A5: For simple and semi-auto machine, we will send manual instruction and teaching video.

For complex operation, we will send the engineers overseas to help client installing, operating and training.

Our Services

What to provide customers with after-sales service?

Pre-sales services:

1. Inquiry and consulting support.

2. Customized design program.

3. Pre-sale training: in order to guarantee all customers fully to operate the machine, if a customer needs, we can help our customer training, includes:

1) Correct operating mode.

2) Correct maintenance way.

3) Remove simple problem of our product.

After-sales service:

Since the shipment date, our company freely assuring period of after-sale maintenance service is:

1) 1year for mechanical part.

2) 6 month for electrical part.

3) Offer lifetime consultation on problems occurred.

Our products include:

1. Silicone strip equipment series.

2. 3D printer filament extruders.

3. LED strip equipment series.

4. Rubber processing machines.

Since our company was founded, over the past 13 yeas, our products have been extensively exported to Africa, Southeast Asia, Latin America, Europe and other markets.