3-Layer Air Bubble Film Machine (2+1 extruders)

Wenzhou Wandun Machinery Co., Ltd.- After-sales Service:1 Year

- Warranty:1 Year

- Type:Sheet Extruder

- Plastic Processed:PE

- Product Type:Extrusion Molding Machine

- Feeding Mode:Multiple Feed

Base Info

- Model NO.:WTPEG 1000

- Assembly Structure:Separate Type Extruder

- Screw:Multi-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Material:LDPE,LLDPE

- Transport Package:Film Packing or Wooden Box Packing

- Specification:10*8*5m

- Trademark:WT

- Origin:China

- Production Capacity:100

Description

Basic Info.

Model NO. WTPEG 1000 Assembly Structure Separate Type Extruder Screw Multi-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Material LDPE/LLDPE Transport Package Film Packing or Wooden Box Packing Specification 10*8*5m Trademark WT Origin China Production Capacity 100Product Description

3-layer air bubble film machine (2+1 extruders)

Product Introduction:

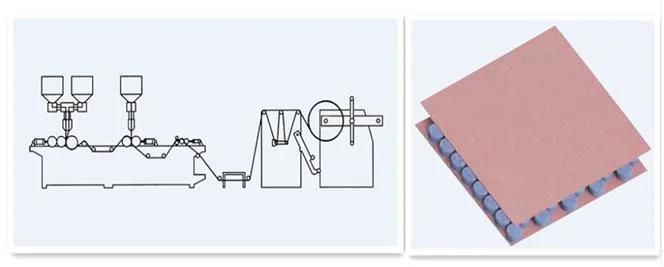

1. Main parts: 3 Extruders, Control Panel, Bubble forming section, Winder;

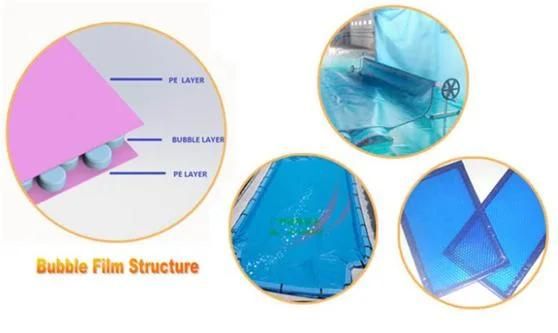

2. To produce 2 layers or 3 layers air bubble film (PE front layer + bubble layer + base layer);

3. Each layer is under individually control, can have different thickness & material formulation and color;

4. Film width from 1,000mm to 3,000mm;

5. Screw L/D ratio is 1:30, it adopts special mixing function and high plasticizing capacity design, with good plasticization, good mixing effect and high output;

6. The bubble forming cylinder adopts special internal circulation chilled water design to ensure perfect bubble forming effect under high speed operation.

Mechanical Transmission Diagram & Bubble Structure

Main Technical Parameters:

| Model | Screw(mm) | Width(mm) | Screw Length : diameter | Main power | Production(kg/h) | Total power(kw) | Weight(kg) |

| WTPEG-3000 | Φ80, Φ90x2 | 3000 | 30:1 | 37+37kw | 280 | 280 | 5000 |

| WTPEG-2500 | Φ75,80 x2 | 2500 | 30:1 | 30+30kw | 260 | 250 | 4500 |

| WTPEG-2000 | Φ75,65x2 | 2000 | 30:1 | 22+22kw | 220 | 200 | 4000 |

| WTPEG-1800 | Φ65,65,65 | 1800 | 30:1 | 18.5+18.5kw | 180 | 180 | 3800 |

| WTPEG-1600 | Φ65,65,55 | 1600 | 30:1 | 18.5+18.5kw | 130 | 150 | 3500 |

| WTPEG-1500 | Φ65,65,55 | 1600 | 30:1 | 18.5+18.5kw | 120 | 150 | 3200 |

| WTPEG-1200 | Φ55,55,55 | 1200 | 30:1 | 11+11kw | 100 | 110 | 3000 |

Q1. What is your terms of packing?

Q1. What is your terms of packing?A: The normal package is making a pallet to protect the machine at the bottom and wrap the whole machine with plastic film packing. If export to EUROPEAN countries, the wooden box will be fumigated. we use PE film for packing or pack it according to customers special request.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages

before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF

Q4. How about your delivery time?

A: Generally, it will take 30 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q6: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.