3 Layers PP Polypropylene Stationery Foam Sheet Extrusion Machine

Qingdao Leader Machinery Co., Ltd.- Product Type:PP Board

- Board Layers:Multilayer

- Screw No.:Single-screw

- Automation:Automatic

- Computerized:Computerized

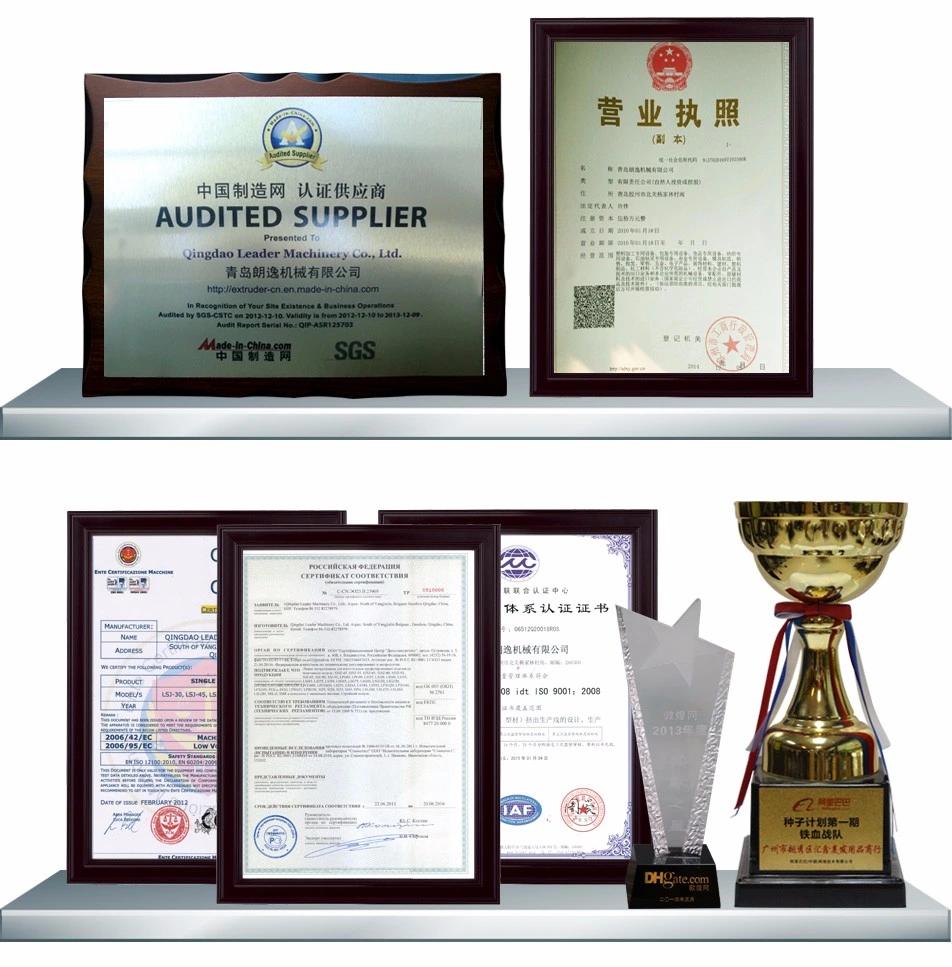

- Certification:CE, ISO9001:2008

Base Info

- Model NO.:LSJ65,65,65

- Customized:Customized

- Condition:New

- Name:PP Foam Sheet Extrusion Machine

- Sheet Width:600-1000mm

- Sheet Thickness:0.8-3mm

- Foam Technology:Chemical Foam

- Extrusion Capacity:150-200kg,H

- Sheet Application:Packing, Stationery

- Die Head Type:T-Type or Coat Hanger Die Head Design

- Processing Technology:Three Rollers Calendars Calibrating

- Main Electrical Parts:ABB, Omoron, Delix, Schnider, Rkc etc

- Guaranteed Time:12 Months

- Transport Package:Wooden Case or Other Moistureproof Packages

- Specification:LSJ65,65,65

- Trademark:Leader Machinery

- Origin:Qingdao of China

- HS Code:8477209000

- Production Capacity:20set,Year

Description

Main data

PART 6 COMPANY CERTIFICATIONS:

PART 7 MACHINE PACKING AND DELIVERY

All the machine parts will be packed in wooden cases or pellets with stretching films on machine body.

PART 8 COMPANY OVERSEA SHOWS AND CONTACT DETAILS:

PART 9 CONTACT INFORMATION:

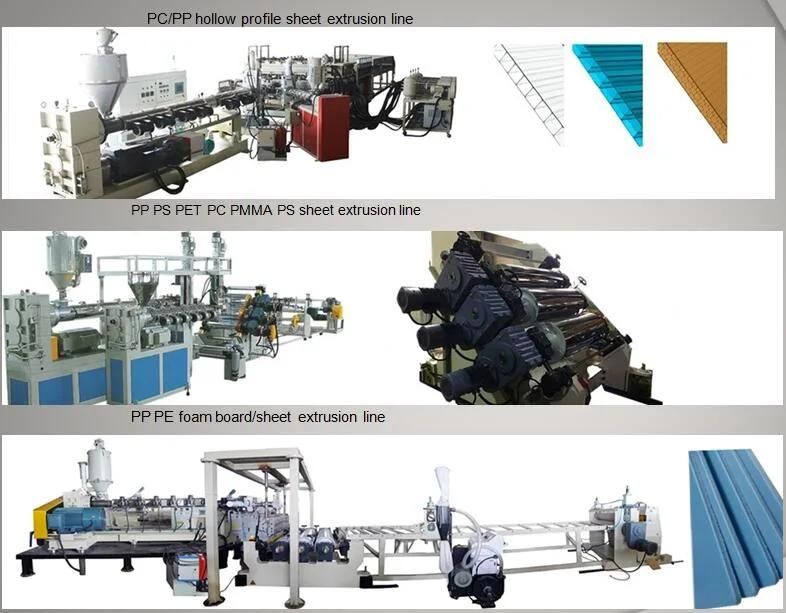

OTHER KINDS OF PLASTIC SHEET/PANEL EXTRUSION LINES:

1. PET sheet extrusion machine:

Processing material: PET virgin pellets(APET or PETG) plus flakes; Or 100% flakes

Thicknes range: 0.15-1.5mm

Net sheet width: 650mm-1500mm(or as per cusotmer's requirement)

Layer structure: Signle layer or multi-layer

Capacity: 350-650kg/h

Application: Thermoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

2. PP/PS sheet extrusion machine:

Processing material: PP/PS virgin pellets plus recycle material;

Thickness range: 0.15-2mm

Net sheet width: 650mm-720mm-1000mm-1300mm-1500mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-1000kg/h

Application: Thermoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

3. ABS/HIPS sheet extrusion machine:

Processong material: ABS/HIPS virgin pellets plus recycle material

Thickness range: 1-6mm

Net Sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 600-800kg/h

Application: Vacuum forming, thermoforming, refrigerator inner layer, suitcase, etc.

4. ABS/PMMA sheet extrusion machine:

Processing material: ABS/PMMA virgin pellets plus recycle material

Thickness range: 1-8mm

Net sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity: 600-800kg/h

Application: Vacuum forming, bathtube, etc.

5. PE sheet extrusion machine:

Processing material: HDPE/LDPE/LLDPE virgin pellets plus recycle material

Thickness range: 1-2.5mm, 3-35mm

Net sheet width: 1200mm-1600mm-1800mm-2500mm-3000mm-40000mm-6000mm-8000mm

Layer structure: Single layer or multi-layer

Capacity: 500kg/h-1200kg/h

Application: Packaging, construction, water-proof, water-drainage, Geomembrane film, etc.

6. PC/GPPS/PMMA sheet extrusion machine:

Processing material: PC/GPPS/PMMA virgin pellets plus recycle material

Thickness range: 1-12mm

Net sheet witdh: 600mm-1220mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 400-600kg/h

Application: Ads., decoration, roofing, etc.

7. PC/PP/PE hollow profile sheet/ sunshine roofing panel machine:

Processing material: PC/PP/PE virgin material plus recycle material

Thickness range: 2mm-4mm-6mm-8mm-10mm-12mm

Net sheet width: 1220mm-2100mm

Layer structure: Single layer or multi-layer

Capacity: 400-600kg/h

Application: Ads. Decoration, roofing, packaging, printing, etc.

8. PVC sheet/edge banding sheet/marble sheet machine:

Processing material: PVC power plus other additive

Thickness range: 0.15-1mm; 1-3mm; 3-12mm

Net sheet width: 650mm-2000mm-3000mm( or as per customer's requirements)

Layer structure: Single layer or multi-layer

Capacity: 300kg/h-500kg/h

Application: Thermoforming, stationery, printing, payment card, SIM card, construction, etc.

9. EVA car interior decoration sheet extrusion line

Processing material: EVA and other additives

Thickness range: 1-8mm

Width range: 1000-1800mm

Layer strcuture: single layer

Capacity: 700-800kg/h

Application: automotive sealing strips, sound insulation cushion, sound absorption sheets,

automobile tail box, fenders, car interior and exterior decoration parts etc.

Layer structure: Single layer or multi-layer

Capacity: 500kg/h-1200kg/h

Application: Packaging, construction, water-proof, water-drainage, Geomembrane film, etc.