Tse Series PP/PE+CaCO3 Plastic Filler Masterbatch Machine Twin Screw Extruder

Nanjing Kairong Machinery Tech. Co., Ltd.- After-sales Service:Online Service

- Warranty:1 Year

- Type:Twin Screw Extruder

- Plastic Processed:PP PE EVA .etc

- Product Type:Granulating Extruder

- Feeding Mode:Multiple Feed

Base Info

- Model NO.:TSE series

- Assembly Structure:Separate Type Extruder

- Screw:Twin-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Motor Design:AC

- Material of Screw and Barrel:High-Speed Steel W6mo5cr4V2

- Screen Changer:Hydrulic

- Transducer:ABB Imported From Switzerland

- Application:Granules

- Screw Material:Stainless Steel

- Packing Type:Wood Case

- Transport Package:Wood Case

- Specification:CE

- Trademark:Nanjing kairong

- Origin:China (Mainland) Jiangsu, Nanjing City

- HS Code:84772090

- Production Capacity:300 Sets,Year

Description

Basic Info.

Model NO. TSE series Assembly Structure Separate Type Extruder Screw Twin-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Motor Design AC Material of Screw and Barrel High-Speed Steel W6mo5cr4V2 Screen Changer Hydrulic Transducer ABB Imported From Switzerland Application Granules Screw Material Stainless Steel Packing Type Wood Case Transport Package Wood Case Specification CE Trademark Nanjing kairong Origin China (Mainland) Jiangsu, Nanjing City HS Code 84772090 Production Capacity 300 Sets/YearProduct Description

plastic color masterbatch pelletizing

DESCRIPTION

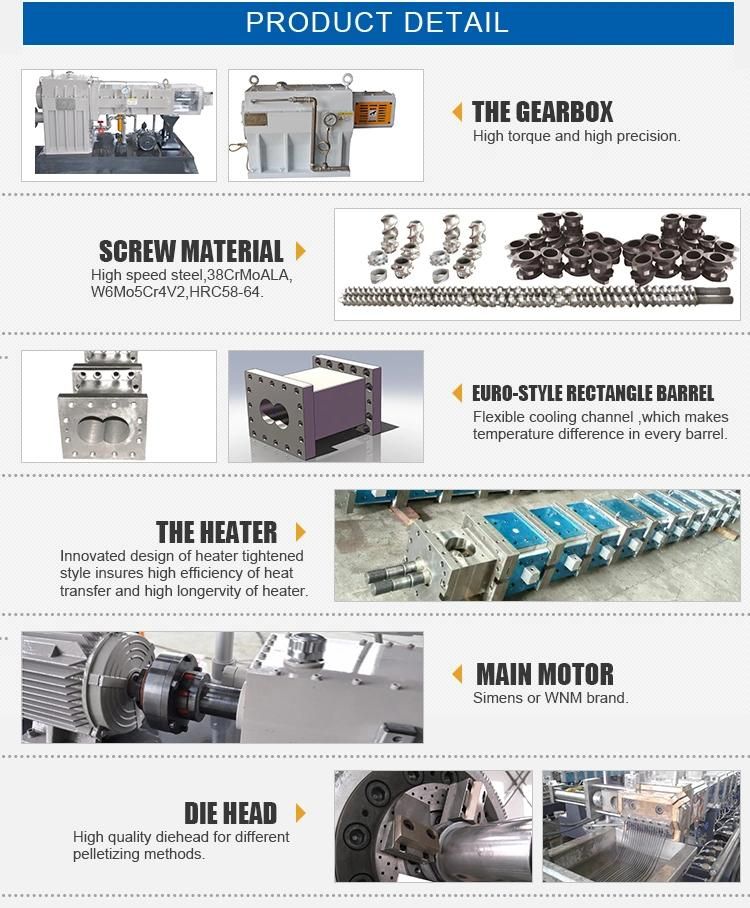

>Screw elements:

Designed by modular principle.

Precise processed, agile combination

Self-cleaning, transmission, compounding

>Barrel Services

Extensive barrel inventory

Field barrel inspections/wear audits

Barrel refurbishment

Packaging & Shipping

Pacakge: Wooden case or Using Anti-rust oil processing, then use stretch film cover extruder against moisture damage.

Shipping: By sea or By express

Company Information

Nanjing HaiSi Extrusion Equipment Co., Ltd is a High-Tech company, which is composed of well-experienced team in R&D, manufacturing technique, sales service and basing on extruder industry for many years. Our company is a professional manufacture of high quality pelletizing extruders for coloring/ dyeing and master batch production, as well as plastic modification and compounding, plastic recycling. Innovative machines are built as per the concept of durability, high efficiency and economical power consumption.

Our machine types:

1. Co-Rotating Parallel Twin Screw Pelletizing Extruders

2. Single Screw Pelletizing Extruders

3. Die Face Cut (Air Cooling) Pelletizing Extruders

4. Double Stage / Double Degassing Recycling Extruders

5. Crushers, Mixers, Storage Tanks, Vibrators, Granulators, Blowers

6. Extruder spare parts

Please contact us if we can help you!

| Mode | Screw Diameter D(mm) | Screw Length(mm) | L/D | Screw Rater N(r/min) | Motor Power P(kw) | Torque T(N.m) | Torque Lvel T/N3 | Capacity Q(kg/h) |

| TSE-40B | 41 | 160 | 32-52 | 600 | 30 | 239 | 5.8 | 90-150 |

| TSE-52B | 51.5 | 210 | 32-64 | 600 | 55 | 438 | 5.5 | 225-250 |

| TSE-65B | 62.4 | 240 | 32-64 | 600 | 90 | 716 | 5.1 | 200-300 |

| TSE-75B | 71 | 290 | 32-64 | 600 | 132 | 1050 | 4.8 | 350-550 |

| TSE-75D | 71 | 290 | 32-64 | 60O | 220-250 | 1990 | 9.2 | 500-1000 |

| TSE-95B | 93 | 360 | 32-64 | 600 | 315 | 2506 | 5.3 | 800-1200 |