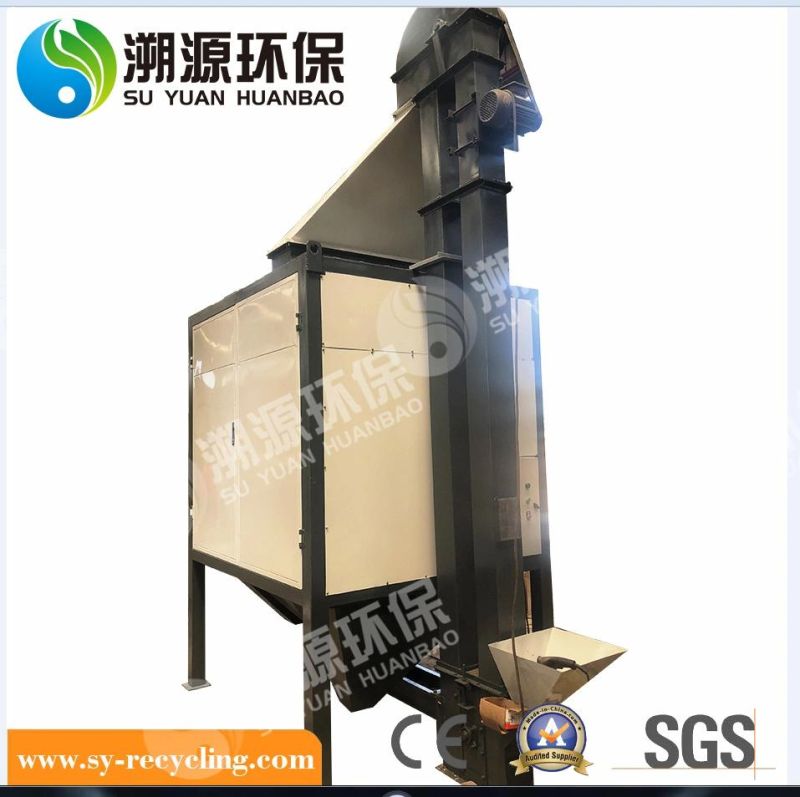

Silicone Rubber Products Automatic Sorting Machine

Xinxiang City Traceability Environmental Protection Equipment Co., Ltd.- After-sales Service:on Line

- Warranty:1 Year

- Material Processed:Rubber Plastic

- Plastic Type:PP

- Screw:Double-Screw

- Automation:Automation

Base Info

- Model NO.:SY-1250

- Computerized:Non-Computerized

- Certification:CE, SGS

- Volatage:Customized

- Capacity:600-1200kg

- Function:Separator

- Application:Waste Treatment

- Color:Customer′s Requirement

- Power:9.5-12.5kw

- Raw Material:Rubber Plastic

- Blades Material:9crsi,D2,SKD-11

- Transport Package:Wooden Packing as Export Standard

- Specification:5580*3150*4250mm

- Trademark:SU YUAN

- Origin:Henan

- HS Code:8479899990

- Production Capacity:30,Month

Description

Basic Info.

Model NO. SY-1250 Computerized Non-Computerized Certification CE, SGS Volatage Customized Capacity 600-1200kg Function Separator Application Waste Treatment Color Customer′s Requirement Power 9.5-12.5kw Raw Material Rubber Plastic Blades Material 9crsi/D2/SKD-11 Transport Package Wooden Packing as Export Standard Specification 5580*3150*4250mm Trademark SU YUAN Origin Henan HS Code 8479899990 Production Capacity 30/MonthProduct Description

SUITABLE RAW MATERIALS

Rubber Plastic Recycling Machines Waste Plastic Recycling Machine is mainly used for the sorting of silica gel, rubber and plastic in the fixed plastics after the crushing of waste household appliances plastics and other plastics, PP plastic and silica gel in medical infusion bottle and infusion bag, waste battery jar and silica gel plug after breaking, plastics and silica gel in electrical broken materials.

PRODUCT FEATURES

1. Pure physical sorting, without any pollution, there is no environmental pressure; equipment energy consumption and operation cost are low.

2. To ensure the accuracy and reliability of the equipment sorting, the core components of the equipment adopts imported brands, the control part adopts PLC automation control and 11-inch man-machine interface touch screen;

3. The inner part which contacts with the material adopts stainless steel and chrome plating, which increases the sorting accuracy and prolongs the service life of the equipment.

4. By using the principles of mirror friction and bouncing, the plastics, silica gel and rubber are accurately separated, and the highest separation purity can reach more than 99%.

5. The equipment is equipped with adjustable automatic feeding system, material lifting system, sorting system, automatic feed return and finished material discharging system. It can be operated by one person.

Technical Paremeter

Model | Power (KW) | Output (KG/H) | Sorting index (%) | External dimension (MM) | Weight (KG) |

| SY-1250 | 9.5 | 600-1000 | 99 | 5580*2280*4250 | 3500 |

| SY-1800 | 12.5 | 800-1200 | 99 | 5580*3150*4250 | 4800 |

WORKING PRINCIPLE

1.Feed hopper: Put the material to be crushed, so as to prevent the material from splashing out;

2.Double shaft cutting system:Using different blades according customers' material;

3.Power system:We choose famous brands of motor in China, can also be configured according to customer needs;

4.Discharging conveyor system:It adopts independent power system, and that power system is integrally fixed on the shredder by bolts, so that the power system can be integrally drawn out.

Raw Materials

Packaging & Shipping

Our Service

1. We not only provide machines but also offer technical guide and market evaluate.

2. We will provide all the machines for the complete production according to customer's requirements.

3. We will provide complete service for factory layout and other information to help customer to build the factory.

4. We will provide good service for machine installation and training, until the customers can run the machines and make stably production.

5. Except one year quality guarantee, we will provide after-sell service for all the life.

6. For long-term cooperation, we always provide good quality, good price and good service to customer.

Company Information

Xinxiang Traceability Environmental Protection Equipment Co. Ltd. was established in the end of 2002.For more than ten years, we have been committed to the research and manufacture of various waste resources separation and sorting recycling equipments. The company has always adhered to the principle of " Service First, Customer First". We will serve the new and old customers with high quality products and service. We will contribute to create a healthy and environmental world together!

FAQ

Q: Why Choose Us?

1). Several Year's Experience

We have rich experience in equipment manufacturing. Our machines have high reputation both at home and abroad (Such as the Middle East, Southeast Asia, Africa and so on more than 10 countries and regions.)

2). Manufacturer, Not Dealer

Factory direct sale makes price more competitive.Customers are always welcome to visit our factory for machine test.

3). Fast Delivery

We promise the goods can be shipped out on delivery date after confirmation of the order.

Q: How do I know the quality of your machine?

A: You can send your sample scrap materials to us and we will test the machine for you without charging the fees. And we can send the machine test video to you. We also warmly welcome you to visit our factory to test our machine personally.

Q: Which brand of motor will you use?

A: We use domestic motor manufatured by Chinese-famous suppliers, but you can choose Siemens or other brand motor. Don't worry about our machine's quality.

Q: Will you dispatch the engineer to guide installation?

A: Yes, according to the customer's requirement, we will dispatch engineers to guide installation and traning about the operation of the machine.