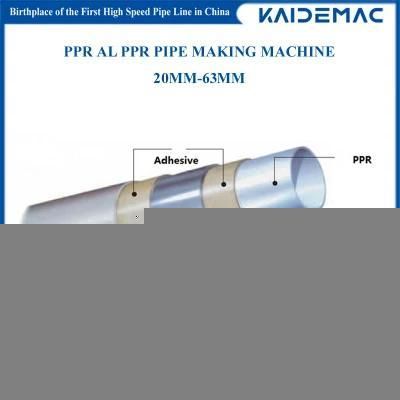

PPR-Al-PPR Pipe Making Machine 20mmp63mm

Weifang Kaide Plastics Machinery Co., Ltd.- Type:Pipe Extruder

- Plastic Processed:PE

- Product Type:Profile Extrusion Molding Machine

- Feeding Mode:One Feed

- Assembly Structure:Integral Type Extruder

- Screw:Single-Screw

Base Info

- Model NO.:ppr al ppr pipe line

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Pipe Diameter:20mm-63mm

- Welding Mode:Overlapped

- Control System:Siemens PLC Control System

- Inverter:ABB Brand

- Electrics:Schneider

- Engineer Service:Engineer Overses Service Is Available

- Line Speed:8-9m,Min

- Transport Package:Soft Package for Sea Transportion

- Specification:PE Pipe Extruder

- Trademark:KAIDE

- Origin:China

- HS Code:847780000

- Production Capacity:200sets Per Year

Description

Basic Info.

Model NO. ppr al ppr pipe line Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Pipe Diameter 20mm-63mm Welding Mode Overlapped Control System Siemens PLC Control System Inverter ABB Brand Electrics Schneider Engineer Service Engineer Overses Service Is Available Line Speed 8-9m/Min Transport Package Soft Package for Sea Transportion Specification PE Pipe Extruder Trademark KAIDE Origin China HS Code 847780000 Production Capacity 200sets Per YearProduct Description

Ultrasonic Overlap Welding AL-Plastic Composite Pipe Line

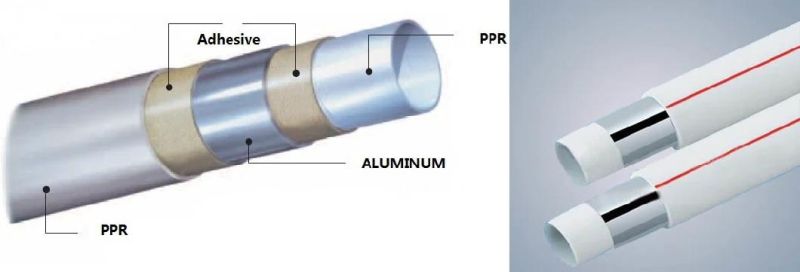

Ultrasonic Overlap Welding AL-Plastic Composite Pipe LineThe Al-Plastics Overlapped Welding machine including below lines: PEX-AL-PEX Pipe Line, PERT-AL-PERT Pipe Line, PPR-AL-PPR Pipe Line,PE-AL-PE Pipe Line.

Technical Data

| Line Model | Extruder Model | L/D | Production Scope | Production Speed | Nominal Power |

| SJ-45 | SJ-45/45/30 | 30/25/25:1 | Ф20-63mm | 8-9m/min | 93KW |

| SJ-65 | SJ- 65/65/30 | 33/33/25:1 | Ф20-63mm | 8-9m/min | 154KW |

High Efficient Extruder

(1) This high efficient extruder of this Al-plastic composite pipe line is specially independently designed by KAIDE company.

Consists of :

(2) Inner Plastic Layer Extruder, Inner Glue Layer Extuer, Outer Plastic Layer Extruder, Outer Glue Layer Extruder

Ultrasonic Overlap Welder

(1) The Aluminum pipe is formed by ultrasonic overlapped welding. It uses high quality and well-known brand welder, with even welding seam and good quality.

Aluminum pipe forming moulds

(1)The technology has been further developed based on original production machine technology.

(2)The Aluminum pipe forming molds and co-extrusion die head molds have been optimized and manufactured by imported high precise CNC machine, which have greatly increased the pipe forming accuracy and production speed.

PLC control system

The five layers aluminum plastic pipe line adopts original Siemens new generation PLC control system with full color screen, which ensures the high speed synchronous control and reliable operating of the whole production line.

PPR Aluminum PPR pipes are also widely used in many industries, such as wall mounted heaters, radiators, air power engineering, water heaters, and domestic hot water pipes. You can safely use this pipes first.

PPR Aluminum PPR pipes are also widely used in many industries, such as wall mounted heaters, radiators, air power engineering, water heaters, and domestic hot water pipes. You can safely use this pipes first.