Wood Plastic Composite Decking Profile Extrusion Machine

QINGDAO TRUSTY PLASTIC MACHINERY CO., LTD.- Warranty:14 Moths

- Product Type:WPC Decking, Fencing, Wall Cladding

- Screw No.:Double-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

Base Info

- Model NO.:SJSZ-65,132

- Customized:Customized

- Condition:New

- After-sales Service:Oversea Installation and Debugging

- Transport Package:Wooden Packing

- Specification:300mm

- Trademark:Trusty

- Origin:Qingdao

- HS Code:84772090

- Production Capacity:30 Set,Month

Description

raw material--mixing--granulation--extrusion and molding--surface treatment4. production steps/process

After get ready wood powder and recycled PP/PE plastic, the first step is mixing them with chemicals, then use WPC granulation machine to make WPC granules.

After get ready wood powder and recycled PP/PE plastic, the first step is mixing them with chemicals, then use WPC granulation machine to make WPC granules.

granulating machine is used for making WPC pellets. The WPC pellets produced by WPC granulating machine can used for making WPC product using WPC machine.The granulating machine consists of parallel double-screw extruder,water cooling system, a granulator and air conveyor cooling system.The feeder and hopper are equipped with mixer to prevent the material blocked up.If customer do not have strict requirements about the appearance of pellets, the granulator can be removed.The pellets extrude by extruder directly, then go for crusher. Can improve the production capacity.

4.2 WPC profile extrusion line

Material: recycled 30% PP/PE+70% wood powder+chemical additives.

Product: WPC decking, WPC wall cladding, WPC fence, WPC pergola..

The WPC profile extrusion line can make WPC granules into WPC products by equipping required mold, we can equip co-extrusion system and online 3D embossing device for making WPC products in high quality with wooden grain, the line also equipped with online cutting device.

4.3 WPC product wood surface making machine

Embossing machine, sanding machine, brushing machine, online embossing machine. these machines is for making WPC products with better wooden feeling design.

Embossing machine, sanding machine, brushing machine, online embossing machine. these machines is for making WPC products with better wooden feeling design.

WPC sanding machine

This machine is used for fixing the size of single extrusion WPC product and doing surface treatment

WPC brushing machine

This machine is used for brushing the WPC product. To do the different surface on WPC product by changing the brushing roller and sanding roller

WPC brushing and sanding machine

This machine is used for doing surface treatment of different WPC product. This machine has the function of sanding machine and brushing machine.

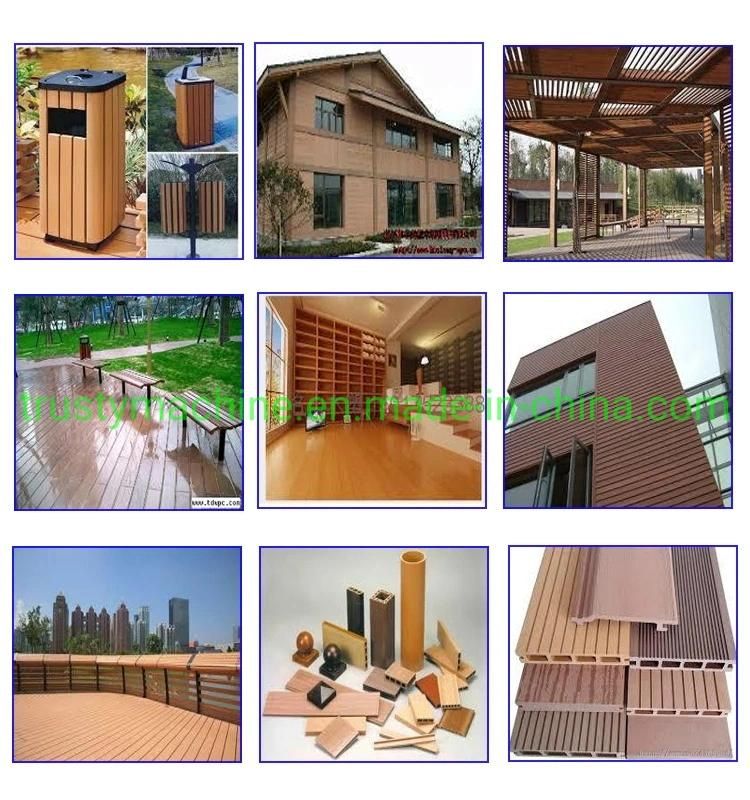

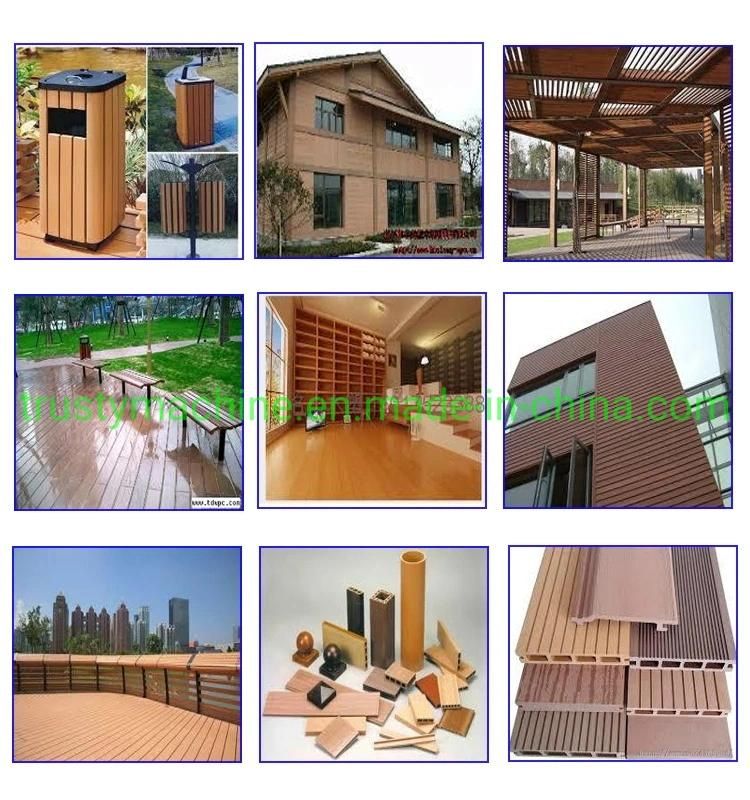

5.PE WPC Products Application

The PE WPC profile extrusion line is suitable for producing the hollow/solid PE WPC profiles. This profile has the advantage of fireproof, waterproof, moisture proof, moth proof, mildew proof and environment friendly. It is mainly used for extruding outdoor decorative WPC profiles, such as gardening landscapes, outdoor landscapes, pallets etc.

The PE WPC profile extrusion line is suitable for producing the hollow/solid PE WPC profiles. This profile has the advantage of fireproof, waterproof, moisture proof, moth proof, mildew proof and environment friendly. It is mainly used for extruding outdoor decorative WPC profiles, such as gardening landscapes, outdoor landscapes, pallets etc.

This extrusion line is for producing co-extrusion PP/PE WPC decking. The decking surface can be made into wood grain by co-extruder. Further more, the machine can be equipped with on-line embossing device the surface can be made into 3D wood grain. The WPC decking has a series of advantage including water-proof, insect prevention, ageing resistant, easy installation, environment friendly and good weathering resistance.6.Comparative advantage of WPC

It is environment friendly.It used recycling materialNo need to be embalmed.No need of daily maintain, long usage life than the wood.No moisture absorbtion, no decay, insect control, no cracking, no deformation.Not sensitive to cold and hot environment.Polyolefin wood-plastic composite have good mechanical properties and can be widely used as load-bearing structural materials.95% of the raw materials of polyolefin wood-plastic materials are recycled materials, so the cost is relatively low and the products can be 100% recycled.

PVC WPC composite material increase impact strength and reduces specific gravity through micro foaming, which is truly imitated wood.

7.FAQ

7.1.WHY CHOOSE US

We are the Professional manufacturer to develop the plastic extrusion machines in Qingdao. Machine quality and customer satisfaction is our pursuit.Be sure we have the strength to provide you with quality machines and perfect service.

7.2.WHAT SERVICES DO WE OFFER?

Pre-sale communication → Design proposal, signature confirmation→

Customized production→ Test machine before shipment →Package &

delivery→ Engineer installation→Training operator → Technical support

7.3.PAYMENT TERMS:

30% of total amount should be paid by T/T as down payment ,the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C by payment(at sight).

7.4.DELIVERY CONDITIONS:

7.4.1 Delivery condition: FOB Qingdao port or CIF destination Port.

7.4.2 Delivery terms: Within 30-60 working days after receipt of advanced payment, the seller should inform the buyer to do inspection,the seller should finish packing of goods and ready for shipment within 15 working days after the seller receipt the full payment.

7.5.WARRANTY TERMS

7.5.1 Warranty period: 12 months, starting from the machine receipt in customer's warehouse

7.5.2 Seller shall grant: services and spare parts, free-of-charge service throughout the entire equipment during warranty period.

7.5.3 long life service: the seller should provide long life service for the sold goods, the buyer pay for needed spare parts after the 12months warranty terms.

7.6.INSPECTION

When the machine finished, the seller should inform the buyer to do inspection before shipment, the seller guaranty good performance of all the sold goods.the seller undertake the material cost for the machine inspection in seller's factory. the buyer should come to seller's factory to do the inspection work, or the buyer could entrust any third party to come to seller's factory to do the inspection work.

7.7.INSTALLATION AND EQUIPMENT COMMISSIONING:

if the buyer requires, the seller should send technician team to buyer's factory for installation and testing the whole line, and the buyer should undertake the whole food/place and round tickets (airplane, food, hotel, and so on), and pay salary to engineer for 100 usd/day/engineer.

4.1 WPC granulation machine

After get ready wood powder and recycled PP/PE plastic, the first step is mixing them with chemicals, then use WPC granulation machine to make WPC granules.

After get ready wood powder and recycled PP/PE plastic, the first step is mixing them with chemicals, then use WPC granulation machine to make WPC granules.granulating machine is used for making WPC pellets. The WPC pellets produced by WPC granulating machine can used for making WPC product using WPC machine.The granulating machine consists of parallel double-screw extruder,water cooling system, a granulator and air conveyor cooling system.The feeder and hopper are equipped with mixer to prevent the material blocked up.If customer do not have strict requirements about the appearance of pellets, the granulator can be removed.The pellets extrude by extruder directly, then go for crusher. Can improve the production capacity.

| Model | L/D ratio | Max.capacity | Motor power | Suitable material | Max.rotating speed | Wood powder percentage |

| SHJ-65 | 40:1 | 200-220kg/h | 75kw | Pe+wood powder | 500r/min | ≤75% |

| SHJ-75 | 40:1 | 300-350kg/h | 90kw | Pe+wood powder | 500r/min | ≤75% |

4.2 WPC profile extrusion line

Material: recycled 30% PP/PE+70% wood powder+chemical additives.

Product: WPC decking, WPC wall cladding, WPC fence, WPC pergola..

The WPC profile extrusion line can make WPC granules into WPC products by equipping required mold, we can equip co-extrusion system and online 3D embossing device for making WPC products in high quality with wooden grain, the line also equipped with online cutting device.

| Model | TPM-65 | TPM-80 |

| Extruder model | SJSZ-65/132 | SJSZ- 80/156 |

| Motor power | 37kw | 75kw |

| Mac.Extrusion capacity | 140-160kg/h | 220-250kg/h |

| Co-extruder(Optional) | SJ35/28 | SJ45/28 |

Embossing machine, sanding machine, brushing machine, online embossing machine. these machines is for making WPC products with better wooden feeling design.

Embossing machine, sanding machine, brushing machine, online embossing machine. these machines is for making WPC products with better wooden feeling design.WPC sanding machine

This machine is used for fixing the size of single extrusion WPC product and doing surface treatment

WPC brushing machine

This machine is used for brushing the WPC product. To do the different surface on WPC product by changing the brushing roller and sanding roller

WPC brushing and sanding machine

This machine is used for doing surface treatment of different WPC product. This machine has the function of sanding machine and brushing machine.

5.PE WPC Products Application

The PE WPC profile extrusion line is suitable for producing the hollow/solid PE WPC profiles. This profile has the advantage of fireproof, waterproof, moisture proof, moth proof, mildew proof and environment friendly. It is mainly used for extruding outdoor decorative WPC profiles, such as gardening landscapes, outdoor landscapes, pallets etc.

The PE WPC profile extrusion line is suitable for producing the hollow/solid PE WPC profiles. This profile has the advantage of fireproof, waterproof, moisture proof, moth proof, mildew proof and environment friendly. It is mainly used for extruding outdoor decorative WPC profiles, such as gardening landscapes, outdoor landscapes, pallets etc.This extrusion line is for producing co-extrusion PP/PE WPC decking. The decking surface can be made into wood grain by co-extruder. Further more, the machine can be equipped with on-line embossing device the surface can be made into 3D wood grain. The WPC decking has a series of advantage including water-proof, insect prevention, ageing resistant, easy installation, environment friendly and good weathering resistance.6.Comparative advantage of WPC

It is environment friendly.It used recycling materialNo need to be embalmed.No need of daily maintain, long usage life than the wood.No moisture absorbtion, no decay, insect control, no cracking, no deformation.Not sensitive to cold and hot environment.Polyolefin wood-plastic composite have good mechanical properties and can be widely used as load-bearing structural materials.95% of the raw materials of polyolefin wood-plastic materials are recycled materials, so the cost is relatively low and the products can be 100% recycled.

PVC WPC composite material increase impact strength and reduces specific gravity through micro foaming, which is truly imitated wood.

7.FAQ

7.1.WHY CHOOSE US

We are the Professional manufacturer to develop the plastic extrusion machines in Qingdao. Machine quality and customer satisfaction is our pursuit.Be sure we have the strength to provide you with quality machines and perfect service.

7.2.WHAT SERVICES DO WE OFFER?

Pre-sale communication → Design proposal, signature confirmation→

Customized production→ Test machine before shipment →Package &

delivery→ Engineer installation→Training operator → Technical support

7.3.PAYMENT TERMS:

30% of total amount should be paid by T/T as down payment ,the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C by payment(at sight).

7.4.DELIVERY CONDITIONS:

7.4.1 Delivery condition: FOB Qingdao port or CIF destination Port.

7.4.2 Delivery terms: Within 30-60 working days after receipt of advanced payment, the seller should inform the buyer to do inspection,the seller should finish packing of goods and ready for shipment within 15 working days after the seller receipt the full payment.

7.5.WARRANTY TERMS

7.5.1 Warranty period: 12 months, starting from the machine receipt in customer's warehouse

7.5.2 Seller shall grant: services and spare parts, free-of-charge service throughout the entire equipment during warranty period.

7.5.3 long life service: the seller should provide long life service for the sold goods, the buyer pay for needed spare parts after the 12months warranty terms.

7.6.INSPECTION

When the machine finished, the seller should inform the buyer to do inspection before shipment, the seller guaranty good performance of all the sold goods.the seller undertake the material cost for the machine inspection in seller's factory. the buyer should come to seller's factory to do the inspection work, or the buyer could entrust any third party to come to seller's factory to do the inspection work.

7.7.INSTALLATION AND EQUIPMENT COMMISSIONING:

if the buyer requires, the seller should send technician team to buyer's factory for installation and testing the whole line, and the buyer should undertake the whole food/place and round tickets (airplane, food, hotel, and so on), and pay salary to engineer for 100 usd/day/engineer.