24 Years Professional UPVC PVC WPC Window Profile Extruder Plastic Machine

Qingdao Tongsan Plastic Machinery Co., Ltd.- After-sales Service:Engineer Team

- Warranty:12 Month

- Type:Profile Extruder

- Plastic Processed:PVC UPVC WPC

- Product Type:Profile Extrusion Molding Machine

- Feeding Mode:One Feed

Base Info

- Model NO.:65,132

- Assembly Structure:Integral Type Extruder

- Screw:Single-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Model No.:Sjsz65,132

- Machine Type:Plastic Extrusion Machine

- Raw Material:Plastic, CaCO3 and Chemical Additives

- Plastic Material:PVC Resin K Value=57-59

- Capacity:150-200kg,Hour

- Extruder Size:65,132 Conical Double Screw Extruder

- Cooling Type:Water Cooling and Vacuum Cooling

- Cutting Machine:Auto Saw Cutting

- Mixing:Hot and Cold Mixer

- Transport Package:Standred Packing

- Trademark:TONGSAN

- Origin:Qingdao

- HS Code:84772090

- Production Capacity:5sets

Description

One set

Special designed PVC Profile co-extrusion machine for making window profile:

Product stacker:

Automatic stacking, 6 meter length. made from stainless steel

Electric control cabinet

ABB inverter

Omron temperature control

Siemens motor

Siemens contractor

Siemens PLC control is optional

Special designed PVC Profile co-extrusion machine for making window profile:

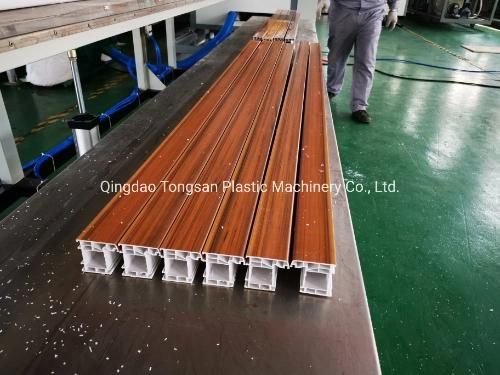

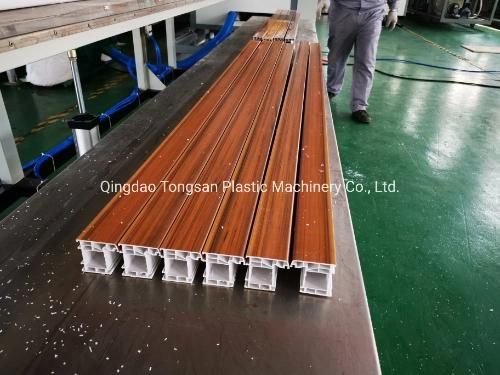

this machine can be used for making PVC +ASA window profile, the main material is PVC layer, and surface coated with ASA material for beautiful wooden color design and anti-sunshine. it will not color fad for outside 10-30 years even under sunshine.

Detailed Images of PVC profile extrusion line with co-extrusion system:

Extruder :Conical double screw extruder specially designed for PVC profile

Model: SJMS65/132 model

Main power: 37KW

Capacity: 150-240 kg/h

Max. product width: 300-600mm

Co-extrusion system: SJ35 co-extruder for ASA material, co-extrusion die head design

Die head and mold for the PVC profile:

Customized size and shape

Mold material: 3Cr17

Cooling method: water cooling and vacuum cooling

calibrating machine

Length of table:4-12 meter customized

material of table: stainless steel

cooling method: water cooling and vacuum cooling.

vacuum pump: 7.5kw*1 sets,+5.5kw*2 sets

water pump: 2.2kw*1 set

haul off machine

Haul off type: double caterpillar

length of haul off: 2.4 meter

control of haul off: frequency control

motor : 1.5 kw

gearbox: double gearbox

Cutting machine for WPC door frame machine

cutting method: automatic cutting

cutting control: PID control

Length: fix length cutting

Product stacker:

Automatic stacking, 6 meter length. made from stainless steel

Electric control cabinet

ABB inverter

Omron temperature control

Siemens motor

Siemens contractor

Siemens PLC control is optional