600-1200mm Plastic Thin Wall Jacket Pipe Extruder/Extrusion Machine for Pre Insulated Pipe ...

Qingdao Huashida Machinery Co., Ltd.- Product Type:PE Pipe

- Screw No.:Single-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

- Customized:Customized

Base Info

- Model NO.:HSD600-1200mm

- Condition:New

- Pipe Diameter:From 630mm To1200mm

- Calibration Method:Vacuum and Water Cooling

- Cutting Method:Planetary Cutting

- PLC:Siemens

- Transport Package:Standard Export Packing

- Specification:Pipe diameter from 630mm to 1200mm

- Trademark:HSD

- Origin:Qingdao, China

- HS Code:8477209000

- Production Capacity:800-1200kg,H for Different Sizes of Pipes

Description

Basic Info.

Model NO. HSD600-1200mm Condition New Pipe Diameter From 630mm To1200mm Calibration Method Vacuum and Water Cooling Cutting Method Planetary Cutting PLC Siemens Transport Package Standard Export Packing Specification Pipe diameter from 630mm to 1200mm Trademark HSD Origin Qingdao, China HS Code 8477209000 Production Capacity 800-1200kg/H for Different Sizes of PipesProduct Description

600-1200mm Plastic Thin Wall Jacket Pipe Extruder/Extrusion machine for Pre insulated Pipe PPU

It is high-efficiency equipment with high speed and energy saving for producing HDPE pipe used as a protective cover of PU foam thermal Pre-insulated Pipe.

It is small in size, easy to operate with the automatic control system and has a long service life.

Production line composition:

-1set Vacuum loader

-1set Hopper dryer

-1set High-efficiency single screw extruder

-1set Vacuum calibration table

-1set Water spraying tank

-1set Hauling machine

-1set Cutting machine

-1set Discharging Frame

---Pipe Usage: outer casing of thermal preinsulated pipe, which is widely used in district heating and cooling, oil,gas and other industrial areas.

---Pipe/jacket diameter range: 110-1680mm

Machine Advantages

---High-efficiency extruder gives larger output, stable performance.

---Pipe wall is average and smooth, to reduce waste of raw material, and pipe thickness is adjustable.

---No need trim edge, once forming.

---High degree of automation, can be operated by one person, saving labor costs.

| Style | PE-110/600 | PE-365/760 | PE-655/1380 | PE-960/1680 | PE-1054/1860 |

| Main Extruder | SJ-75/33 | SJ-90/33 | SJ-120/33 | SJ-150/33 | SJ-150/33 |

| Pipe diameter | Φ110-600mm | Φ365-760m | Φ655-1380mm | Φ960-1680mm | Φ1054-1860mm |

| Capacity | 250-350kg/h | 400-500kg/h | 700-900kg/h | 1000-1200kg/h | 1000-1250kg/h |

| Installed power | 160kw | 240kw | 480kw | 580kw | 580kw |

| Length | 30m | 32m | 36m | 40m | 45m |

1. High-efficiency single screw extruder

---Single screw is with barrier & mixing head; new model barrel with slotting (channel), Both make the security of good plasticization, large output and stable performance.

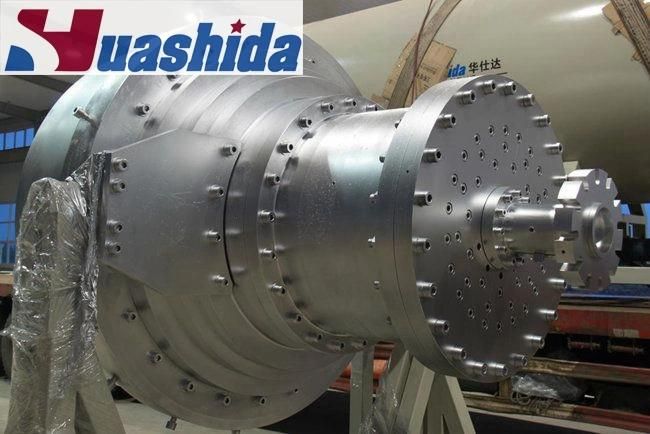

Die-Head

Die-head is mainly composed of mandril, neck mold, spiral body, cover, die-head body, bolts, and heating rings.

The inside surface touching with plastic materials is polished and chrome plated to ensure plastic materials flow smoothly and to ensure no rusting. The uniformity of pipe wall thickness can be adjusted by bolts. The copper calibrating sleeve fixed in die-head is mainly used to cool down the fresh pipe and to calibrate the pipe outer diameter.

3. Vacuum Calibration Tank

Vacuum calibration tank is mainly composed of frame, stainless steel tank, vacuum system, spray cooling system, position adjustment device. The vacuum pump exhausts the air from the sealed tank to pressurize the fresh pipe cling to calibrating copper sleeve and to calibrate the outer diameter. Spray nozzles spray cooling water from all directions on pipe surface to cool down the pipe promptly.

4. Caterpillar Haul-off Machine

The haul-off machine is mainly composed of driving device, caterpillar, clamping structure, adjusting system, side plate, and foundation bed. Haul-off caterpillars are driven by AC motor with frequency conversion control to adapt to different extrusion speed.

The automatic length measuring device realizes cutting at a set length.

5. No-Dust Cutter

It adopts the blade punching principle to realize no-dust cutting. It is mainly composed of cutting devices, clamping devices, structure synchronous movement device and frame.

6.Control system

The complete line could be controlled by PLC, with the good human-machine interface, all technical parameters could be set and indicated by touching the screen. The controlling system can be designed according to customers' requirements.

7.Discharging Frame

The table surface is made of stainless steel. It adopts pneumatic overturn and discharging automatically.

CUSTOMER VISIT

DELIVERY

WORKSHOP