Plastic PP/PS Sheet Production Machine Extrusion Line with Ce and ISO

Qingdao Suke Machinery Co., Ltd.- Product Type:PP Board

- Board Layers:Single Plate

- Screw No.:Single-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

Base Info

- Model NO.:SJ90,33

- Customized:Customized

- Condition:New

- Matertial:PP

- Button:Schneider

- Intelligent Temperature Controller:Omron

- Control System:PLC Control System

- Warranty:12monthes

- After Sale Service:Life Long with Professional After Sale Team

- Machine Color:as Request

- Raw Material:PP Granule

- Inverter:ABB

- Contactor:Schneider

- Transport Package:According to Your Requirement

- Specification:ISO9000 CE

- Trademark:SUKE

- Origin:Qingdao, China

- HS Code:84775900

- Production Capacity:40sets,Year

Description

Basic Info.

Model NO. SJ90/33 Customized Customized Condition New Matertial PP Button Schneider Intelligent Temperature Controller Omron Control System PLC Control System Warranty 12monthes After Sale Service Life Long with Professional After Sale Team Machine Color as Request Raw Material PP Granule Inverter ABB Contactor Schneider Transport Package According to Your Requirement Specification ISO9000 CE Trademark SUKE Origin Qingdao, China HS Code 84775900 Production Capacity 40sets/YearProduct Description

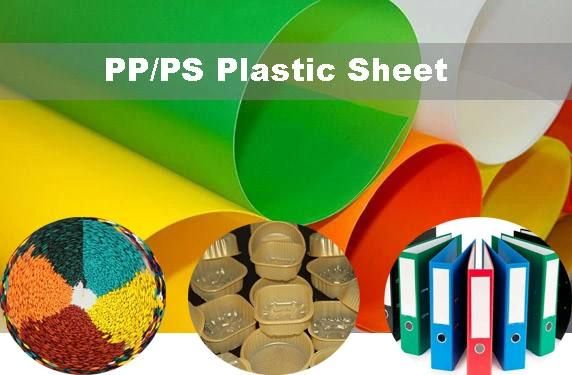

Plastic PP/PS Sheet Production Machine Extrusion Line with CE and ISO

Characteristics and Applcation of Sheet:

It has such characteristics as high intensity, good temperature resistance and corrosion resistance. Can be used to improve intensity, toughness and rigidity, can be embossed and frosted on the surfaces as well. Applicable to various industries such as packaging, printing, stationery, gifts manufacturing, etc.

Gift/ad/file bag, lamp cover, food packing box, etc.

Thickness between 0.2-30mm, width between 600-2200mm.

EQUIPMET LIST:

1. Single Screw Extruder

2. Mould

3. Three Roller Calander

4. Roller Temperature Controller

5. Cooling Rollers

6. Haul-off and Cutting Device

7. Stacker,

| Model | SK-130/38-2200 | SK-120/38-1400 |

| Raw material | PP/PS | PP/PS |

| Width | 2100 mm | 1300 mm |

| Thickness | 1.5-10 mm | 1-10 mm |

| Spec of extruder | 130/38; 45/30 | 120/38; 45/30 |

| Output | 550 kg/h | 450 kg/h |

TRADE TERMS

- Payment Term: 30% for prepayment by T/T, 70% for balanced payment by T/T, or L/C can be acceptable

- Delivery Time: 40 days after receipt of prepayment.

- Packing Method: Packing film or wooden case

- Guaranteed Time: 12 months

- When machine finished, we will invited client come to our factory to check the machine and do the machine test. If machine is ok, then client pay for the balance. And inspect machine load the container.

- When machine arrives client's factory, if client needs, we will send 1-2 engineer to client's factory do the machine installation and running test, and also train the local worker how to operate and maintain the machine. It is chargeable.

- If have any question or problem on machine operation or maintain, welcome to contact to us by email or calling. We stand by 24 hours.