600kg/H PVC WPC Door Board Extrusion Production Line

Qingdao Weier Plastic Machinery Co., Ltd.- Type:Profile Extruder

- Plastic Processed:WPC

- Product Type:Extrusion Machine

- Feeding Mode:Multiple Feed

- Assembly Structure:Integral Type Extruder

- Screw:Twin-Screw

Base Info

- Model NO.:SJ-92,188 SJ-80,156

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Project Name:PVC WPC Door Board Extrusion Line

- Raw Materials:PVC Powder, Wood Powder, Chemicals, etc

- Width of Door:860mm, etc

- Extruder:Conical Twin Screw Extruder

- Transport Package:Simple Packing as Per Export Standard

- Specification:National

- Trademark:WEIER

- Origin:Qingdao City, Shandong Province, China

- HS Code:84772090

- Production Capacity:5sets Month

Description

Basic Info.

Model NO. SJ-92/188 SJ-80/156 Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Project Name PVC WPC Door Board Extrusion Line Raw Materials PVC Powder, Wood Powder, Chemicals, etc Width of Door 860mm, etc Extruder Conical Twin Screw Extruder Transport Package Simple Packing as Per Export Standard Specification National Trademark WEIER Origin Qingdao City, Shandong Province, China HS Code 84772090 Production Capacity 5setsMonthProduct Description

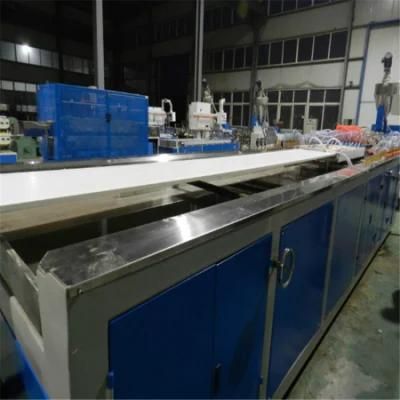

PVC WPC Door Board Extrusion Production LineIntroduction

WEIER series of wide plastic sheet production line mainly used: PVC + wood flour. Production overall door, construction and other wood-plastic plate Templates before the extrusion.

The WPC PVC Door Board Poduction Line use the original wood-plastic technology companies and formula.

Plates can be based on different sections, according to the different uses of board products, design different proportions.

Traction machine use unique technique, with steady work, good reliability, great traction, to increase the use of special vacuum stereotypes swirl cooling system to facilitate cooling stereoty[es to meet the needs of the production features of wide wood plastic door plate.

PVC hollow door panel wood plastic machine/machinery including:

2.1)SJSZ-80/156 twin conical screw extruder

2.2)vacuum calibrating table with mold

2.3)haul-off: Machine frequency speed-controlling

2.4)transmitting bracket equipment

2.5)cutter(across cutting by saw)

2.6)material-conveying table

Our company

Qingdao Weier Plastic Machinery Co., LTD is the director member of WPCC (Plastic &Wood Production Council of Chinese Plastic Community), now we are Plastic Engineering Technology Research Institute of Qingdao Science and Technology University Test and Industrialization center. We cooperated with many domestic universities to develop special plastic machines to meet domestic and foreign customer's requirement and have a strong association with many macromolecule and chemical majors of many universities. At the same time we bring in and absorb advanced processing engineering of foreign plastic machines to realize chain service of technique and machines.