Hot Sale Asia Durable PVC Glazed Roof Tile Sheet Forming Making Machine

Jiangsu Acemien Machinery Co., Ltd.- Type:Sheet Extruder

- Plastic Processed:PVC

- Product Type:Extrusion Molding Machine

- Feeding Mode:Multiple Feed

- Assembly Structure:Separate Type Extruder

- Screw:Twin-Screw

Base Info

- Model NO.:ASM-G-01

- Engagement System:Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Transport Package:Wooden Case with Plastic Film

- Specification:25*3*3.5m

- Trademark:acemien

- Origin:China

- HS Code:84778000

- Production Capacity:>1000pieces,a Year

Description

Ridge roof forming machine(Optional)

1. Flat sheet haul-off unit

2. Oven

3. Ridge tile forming unit

4. Ridge tile mold (4sets)

Project evaluation

1. Raw material & Final product:

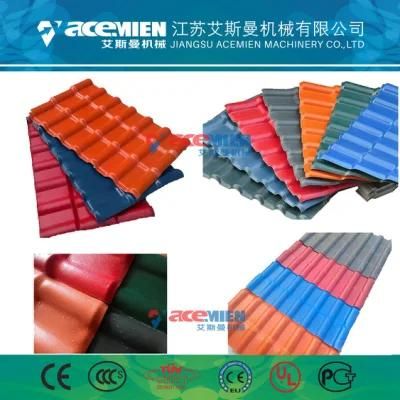

Picture/Diagram of final product:

2. Work condition (provide by customer)

3. Energy consumption

Turnkey project service:

1. We will provide all the machines for the complete production according to customer's requirements.

2. We will provide complete service for factory layout and other information to help customer to build the factory.

3. We can also provide the raw material to the customer if you need.

4. We will provide good service for machine installation and training, until the customers can run the machines and make stably production.

5. Except one year quality guarantee, we will provide after-sell service for all the life.

6. For long-term cooperation, we always provide good quality, good price and good service to customer. We are the professional and trustable supplier for turnkey projects. Let us do win-win business together.

1. Flat sheet haul-off unit

2. Oven

3. Ridge tile forming unit

4. Ridge tile mold (4sets)

Project evaluation

1. Raw material & Final product:

| Raw material & formulation | PVC powder, CaCO3, CPE, PE-WAX, Stearic acid, Compound stabilizer, ACR, paraffin, ASA granule |

| Description final product & Output capacity | Two layers PVC+ASA Co-extrusion Glazed tile; Width: 1040mm, Thickness: 2~3mm; Output: 300-400kg/h(Depending on CaCO3 proportion) For 2.5mm thickness, Capacity about 2000 Sqr/day |

2. Work condition (provide by customer)

| Warehouse/Workshop | Dimension (M*M*M): 25(Length)×5(width) ×3.5 (Height) Crane: Machine positioning |

| Temperature & Humidity | ≤40ºC, ≤95% |

| Power supply | 3-phase, 380 V, 50 Hz(or customized) |

| Wire/cables: | Wires/cables from power supply to control cabinet of this production line; |

| Cooling Water hose/pipe | Water supply to machines and pools |

| Lubrication oil: | Sinopec, Exxon mobile |

| Compressor | 7.5KW(0.6-0.8MPa) |

3. Energy consumption

| Installation power | Total 287KW, Actual consumption about 70% Suggested 200kVA transformer Needing at least 160kVA transformer |

| Cooling Water | ≤20ºC, ≥0.3MPa, ~5-6tons/hr |

| Compressed air | 0.3m3/min, >0.6MPa |

| Manpower | 3 Persons/shift(24 hours need 2-3 shifts) |

Turnkey project service:

1. We will provide all the machines for the complete production according to customer's requirements.

2. We will provide complete service for factory layout and other information to help customer to build the factory.

3. We can also provide the raw material to the customer if you need.

4. We will provide good service for machine installation and training, until the customers can run the machines and make stably production.

5. Except one year quality guarantee, we will provide after-sell service for all the life.

6. For long-term cooperation, we always provide good quality, good price and good service to customer. We are the professional and trustable supplier for turnkey projects. Let us do win-win business together.