Hight Capacity Spc Floor/Sheet/ Board/Roofing Tile Sheet& Plate Extrusion/Extruder ...

Wuxi Boyu Plastic Machinery Co., Ltd.- Type:Sheet Extruder

- Plastic Processed:PVC

- Product Type:Extrusion Molding Machine

- Feeding Mode:One Feed

- Assembly Structure:Integral Type Extruder

- Screw:Twin-Screw

Base Info

- Model NO.:SJSZ180

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Don′t Exhaust

- Automation:Automatic

- Computerized:Computerized

- Dimension (L*W*H):60m*5m*8m

- Online Embossing:Better Than 95%

- Plant Thickness:2~9mm

- Main Motor:Siemens or Weg Ie3

- Transport Package:PE Wrapping Film, Fumigating Wooden Cases.

- Specification:CE, SGS

- Trademark:BOYU

- Origin:Wuxi, Jiangsu, China

- HS Code:8477209000

- Production Capacity:4000kg,H

Description

Basic Info.

Model NO. SJSZ180 Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Dimension (L*W*H) 60m*5m*8m Online Embossing Better Than 95% Plant Thickness 2~9mm Main Motor Siemens or Weg Ie3 Transport Package PE Wrapping Film, Fumigating Wooden Cases. Specification CE, SGS Trademark BOYU Origin Wuxi, Jiangsu, China HS Code 8477209000 Production Capacity 4000kg/HProduct Description

High Capacity 3000kgs-4000kgs Per Hour Conical-Twin Screw Extruder SPC Vinyl Floor Extrusion LineAs SPC flooring equipment inventor, we Boyu Extruder are always keep moving on new research and development. At the beginning of 2021, we have produced the new super output performance extruder SJSZ180, and firstly provided 6 sets to our good partnership customer. After several months successful operation, they have expanded to 18sets. We now are in great confidence to launch these new productivity-enhancing to all of our customers and help them enjoy more BENEFITS.

- SAVE PLANT SPACE

- SAVE LABOUR COST

- SAVE ENERGY CHARGE

- SAVE SCREW COST

I. Basic Information:

| No. | Items | Data |

| 01 | Operation Conditions | 380V/3 phases/50Hz, DC24V. (customize) |

| 02 | Raw Material | PVC powder, calcium carbonate, stabilizer, lubricant, small materials |

| 03 | Main material proportion | PVC: CACO3= 1:3 |

| 04 | Product specifications | Width:1050/1350mm, Thickness:2-9mm |

| 05 | Machine Fabrication Certificate | CE/UL/SGS/CSA |

| 06 | Electric components certificate | CE/UL/SGS/CSA |

2. Product Configuration:

1) Main motor: SIEMENS BEIDE/ WEG IE3

2) Contactor: SIEMENS

3) Auxiliary relay: SCHNEIDER

4) Temperature control system: DELTA PLC Touch Screen Control System

5) Inverter: ABB

6) All Extruder by the DELTA PLC Controlled.

3. Production Introduction:

| Item | SPC flooring board |

| Origin | Wuxi, China |

| Thickness | 2~9mm |

| Length | As your request |

| Density | 1.9-g/cm3 |

| Size | 1220*2440mm,1560*3050,2050*3050mm |

| Color | White, black, red, blue, yellow, green, gray, or as your request. |

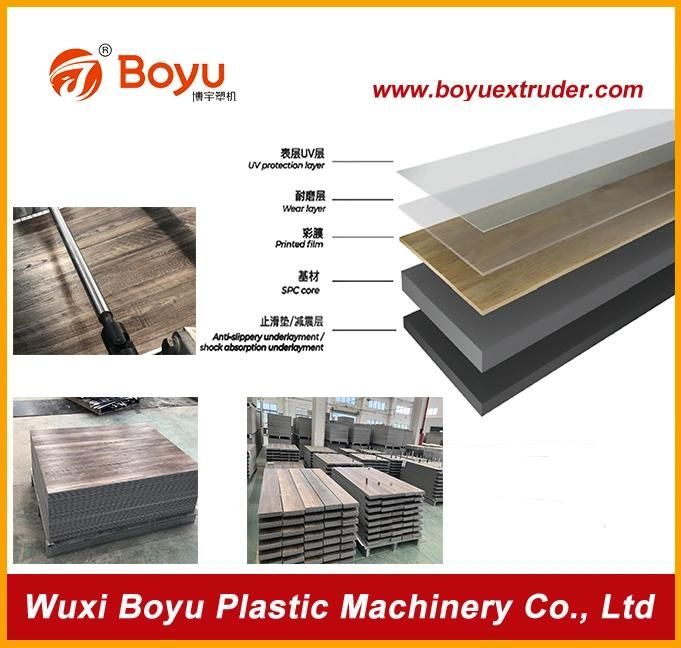

| Applications | 1.Building outdoor wall board, indoor decoration board, decorative Wall Panel, furniture Board, cupboard, partition board in office and house. 2.Advertisement Board, screen printing, flat solvent printing, engraving, billboard and exhibition display. 3.Chemical anti-corrosion project, special cold project, environmental protection. 4. Indoor flooring base board. |

| Features | 1. Waterproofing. 2. Fire retardant and self-extinguishing. 3. Heat preservation. 4. Sound-insulated. 5. Insulation. 6. Non-corrosion. 7. Non-toxic. 8. Tough, rigid with the high impact strength. 9. Stable color retention. |

4.Production process:

Extruder → T-die → Five Roller Calender → Oil temperature controller → Traction Machine → Cutting Machine → Automatic Flipper & Stacker

5.Finished Products:

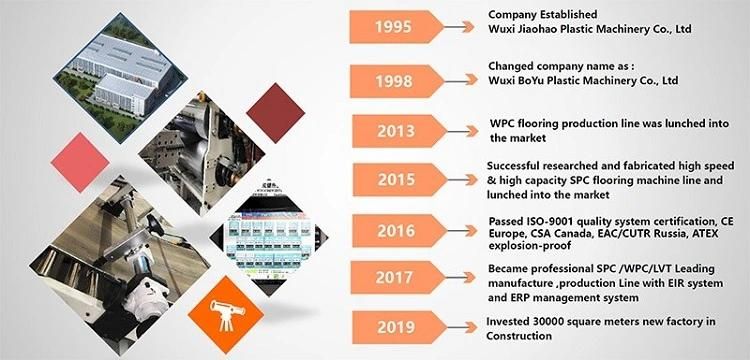

6. Boyu Company Development:

7.Our Service:

1. Pre-sale service:

To provide market research information and consultation;

To provide all kinds of convenience and market service;

To help customers make project planning and systematic analysis;

To maximize customer's satisfaction.

2. After-sale service:

To install products and test products for customers;

To provide the formulas and technologies of relevant products and the information of chemical materials manufacture;

To provide technical direction according to customers' requirements;

To provide technical training for clients' employees;

To be responsible for maintenance service, door-to-door service under necessary circumstance.

3. Technology Support

Provide different products for formula and material supplier.

Production technology&Technical guidance.

Technicians dispatching for Guidance and technology exchange.

8. Shipping:

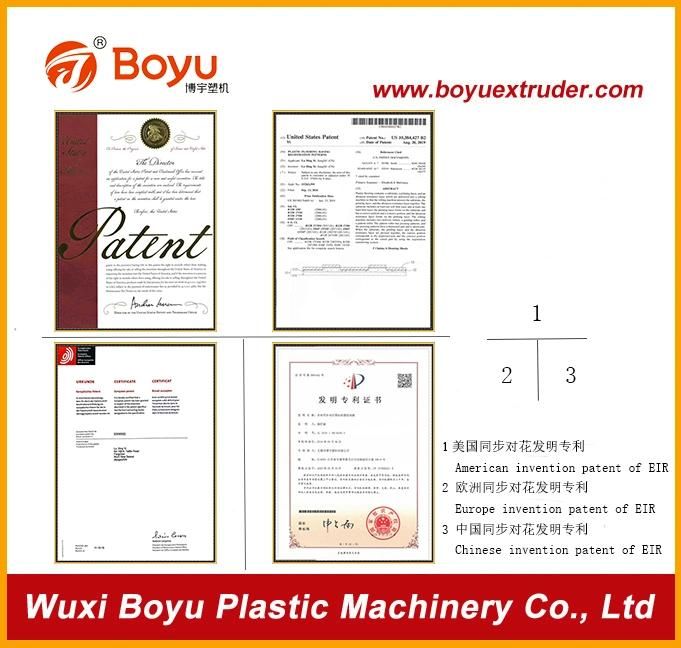

9. Certificate: