Pre-Insulated Pipe HDPE Jacket Tube Extrusion Line

Qingdao Huashida Machinery Co., Ltd.- Type:Pipe Extruder

- Plastic Processed:PE

- Product Type:Extrusion Molding Machine

- Feeding Mode:One Feed

- Assembly Structure:Integral Type Extruder

- Screw:Single-Screw

Base Info

- Model NO.:HSD

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Don′t Exhaust

- Automation:Automatic

- Computerized:Computerized

- Diameter:110mm-1680mm

- Voltage:380V 50Hz

- Transport Package:Standard Package

- Specification:EN253, EN448, EN728, ISO1133, ISO8501-1. ISO9001

- Trademark:HSD

- Origin:Qingdao China

- HS Code:8477209000

- Production Capacity:20 Unit,Year

Description

Basic Info.

Model NO. HSD Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Diameter 110mm-1680mm Voltage 380V 50Hz Transport Package Standard Package Specification EN253, EN448, EN728, ISO1133, ISO8501-1. ISO9001 Trademark HSD Origin Qingdao China HS Code 8477209000 Production Capacity 20 Unit/YearProduct Description

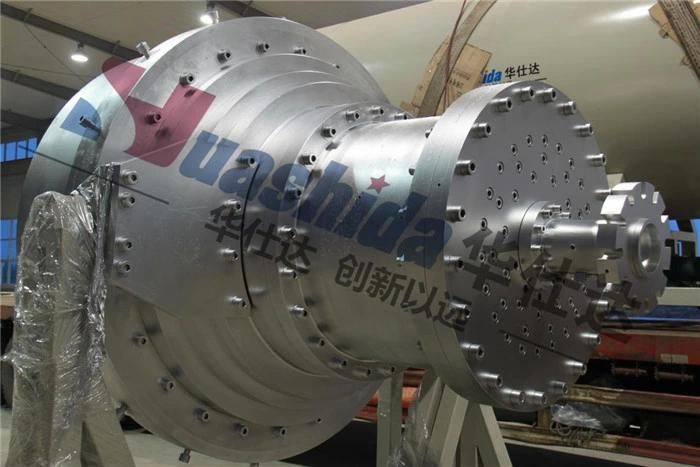

Pre-Insulated Pipe HDPE Jacket tube Extrusion Line

Vacuum calibrating method pre-insulated pipe outside casing extrusion line is the most advanced and popular machinery by now.

This is an integration design composed by extrusion, vacuum calibrating, cooling, pulling, cutting, stacker. Great performance in automatic operation, extrusion capacity, steady and long life service life etc. Especially compared with the line with internal pressure method, vacuum calibrating method is much better than it for stiffness, pressure resistance and surface smooth.

This pipe extrusion line mainly includes single screw extruder, molds, vacuum calibrating water tank, spray water cooling tank, haul-off machine, cutting machine and bracket.

Plastic Pipes produced by this line has excellent stiffness, flexibility, high mechanical strength, resistance of environmental stress cracks, resistance to creep deformation, heat-linkage and so on. It has become the first choice for the city gas pipe, water supply pipe, foundation pipe, landfill collection pipe, stormwater, geothermal heating etc.

| Style | PE-365/760 | PE-420/960 | PE-850/1372 | PE-960/1680 |

| Main extruder | SJ-90/33 | SJ-90/33 | SJ-120/33 | SJ-150/33 |

| Pipe diameter | Φ365-760mm | Φ 420-Φ 960 mm | Φ 850-Φ 1372 mm | Φ 960-Φ 1680mm |

| Capacity | 450-500kg/h | 550~700 kg/h | 700~900 kg/h | 800-1200kg/h |

| Installed power | 360kw | 380 kw | 440 kw | 580kw |

| Length | 28m | 36 m | 40 m | 48m |

Qingdao Huashida Machinery Co., Ltd is a professional plastic extrusion production line manufacture since 2003. The factory covers 34000 square meters. Our products such as HDPE pressure pipe for gas or water transmission, structural wall pipe extrusion line, corrugated pipe extrusion line . The products have been exported to Middle East, Russia, Africa. Turkey, Korea.

Our factory locates in Cheng yang Industrial area, Qingdao ,Shandong Province. we have been approved and got certificate ISO90001:2008 by SGS. All the customers are welcome to visit the factory.

If you need more information about this machine. just call us , we can give you consulting service for this machine

Our products mainly include

Single Screw Extruder & Twins Conical Extruder

Vacuum Calibrating pre-insulated pipe outside HDPE casing Extrusion line

20-630mm Single/multi layer HDPE Pipe Extrusion Line

200-3000mm HDPE Spiral Corrugated Pipe Extrusion Line

Fiberglass reinforced PP-R Pipe Co-extrusion line

Plastic Sheet/ Plate Single/multi layer Extrusion Line

PVC Fiber & Steel Wire Reinforced Hose Line

Hand Extruder / Electro-fusion Welder

Heat Shrinkable sleeves (Normal style & Fiber Reinforced style)

Electro-fusion Girth Welding joint closure & Electro-fusion welded belt