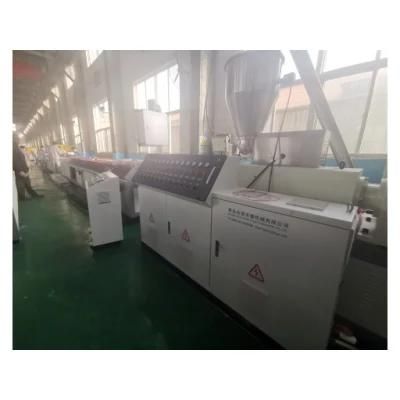

Wood Plastic WPC Door Frame Profile Extrusion Machine

Qingdao Tongsan Plastic Machinery Co., Ltd.- Product Type:PVC Profile

- Screw:Double-Screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE

- Customized:Customized

Base Info

- Model NO.:SJMS65,132

- Machine Type:Plastic Extrusion Machine

- Raw Material:Wood, Plastic, CaCO3 and Chemical Additives

- Wood Material:40-100 Mesh Wood Powder

- Plastic Material:PVC Resin K Value=57-59

- CaCO3:800-1200 Mesh Actived CaCO3

- Percentage of Plastic:50%

- Percentage of Wood:20-40%

- Percentage of CaCO3:20-40%

- Capacity:150-200kg,Hour

- Extruder Size:65,132 Conical Double Screw Extruder

- Cooling Type:Water Cooling and Vacuum Cooling

- Pull off Machine:Double Caterpillar Pull off

- Cutting Machine:Auto Saw Cutting

- Mixing:Hot and Cold Mixer

- Mold:Customized Size and Shape

- Transport Package:Film Wrapping, Wooden Case, Strong Pallet

- Specification:0-300mm

- Trademark:Tongsan

- Origin:China

- HS Code:84772090

- Production Capacity:10 Sets,Month

Description

Extruder for PVC WPC door frame machine

Conical double screw extruder specially designed for making PVC WPC door frame.

Model: SJMS65/132 model

Main power: 37KW

Capacity: 150-240 kg/h

Max. product width: 300-600mm

Die head and mold for the WPC door frame making machine:

For making solid door frame, it is necessary to increase the calibrator length to be 300mm*3 piece or 300*4 piece. and the water cooling tank should be 2000mm*2 pcs or 3000mm*2 pcs

calibrating machine for WPC door frame machine.

Length of table: 8meter customized

material of table: stainless steel

cooling method: water cooling and vacuum cooling.

vacuum pump: 7.5kw*1 sets,+5.5kw*2 sets

water pump: 2.2kw*1 set

haul off machine for WPC door frame machine

Haul off type: double caterpillar

length of haul off: 2.4 meter

control of haul off: frequency control

motor : 1.5 kw

gearbox: double gearbox

Cutting machine for WPC door frame machine

cutting method: automatic cutting

cutting control: PID control

Length: fix length cutting

Electric control cabinet

ABB inverter

Omron temperature control

Siemens motor

Siemens contractor

Siemens PLC control is optional

WPC door frame made by Tongsan WPC door frame extrusion line.

customized size and shape, professional formula for high quality product.

FAQ

1, DO YOU PROVIDE OEM SERVICE?

we accept OEM order to design the machine according to customer's special requirements.

2, HOW CAN I GET THE TECHNICAL PARAMETERS?

Please contact us for sending you detailed quotation with technical parameters

3, WHAT IS THE WARRANTY TERMS?

3.1 WARRANTY PERIOD: 12 MONTHS, STARTING FROM THE FIRST DAY OF RUNNING MACHINES IN CUSTOMER'S WAREHOUSE

3.2 SELLER SHALL GRANT: SERVICES AND SPARE PARTS, FREE-OF-CHARGE SERVICE THROUGHOUT THE ENTIRE EQUIPMENT WARRANTY PERIOD.

3.3 LIFELONG SERVICE: THE SELLER SHOULD PROVIDE LIFELONG SERVICE FOR THE SOLD GOODS, THE BUYER PAY FOR NEEDED SPARE PARTS AFTER THE 12MONTHS WARRANTY TERMS.

4, WHAT IS THE DELIVERY CONDITIONS?

4.1 DELIVERY CONDITION: FOB QINGDAO PORT.

4.2 DELIVERY TERM: WITHIN 45 WORKING DAYS AFTER RECEIPT OF ADVANCED PAYMENT, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION. THE SELLER SHOULD FINISH PACKING OF GOODS AND READY FOR SHIPMENT WITHIN 15 WORKING DAYS AFTER THE SELLER RECEIPT THE FULL PAYMENT.

4.3 SUPERVISION OF LOADING:THE SELLER SHOULD INFORM THE BUYER EXACTLING LOADING TIME, THE BUYER SHOULD ARRANGE FOR SUPERVISION OF LOADING.

5, WHAT IS THE PAYMENT TERMS?

5.1 INSTALLMENT I: 30% OF TOTAL PAYMENT TO BE PAID AT ADVANCE

5.2 INSTALLMENT II: THE BALANCE 70% OF TOTAL PAYMENT TO BE PAID BY TT OR LC AT SIGHT

6, HOW TO DO THE INSPECTION WORK BEFORE SHIPMENT?

WHEN THE MACHINE FINISHED, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION BEFORE SHIPMENT, THE SELLER GUARANTY GOOD PERFORMANCE OF ALL THE SOLD GOODS.THE SELLER UNDERTAKE THE MATERIAL COST FOR THE MACHINE INSPECTION IN SELLER'S FACTORY. THE BUYER SHOULD COME TO SELLER'S FACTORY TO DO THE INSPECTION WORK, OR THE BUYER COULD ENTRUST ANY THIRD PARTT TO COME TO SELLER'S FACTORY TO DO THE INSPECTION WORK.

7, HOW TO DO THE INSTALLATION AND EQUIPMENT COMMISSIONING?

IF THE BUYER REQUIRES, THE SELLER SHOULD SEND TECHNICIAN TEAM TO BUYER'S FACTORY FOR INSTALLATION AND TESTING THE WHOLE LINE, AND THE BUYER SHOULD UNDERTAKE THE WHOLE FOOD/PLACE AND ROUND TICKETS (AIRPLANE, FOOD, HOTEL, AND SO ON), AND PAY SALARY TO ENGINEER FOR 80 USD/DAY/ENGINEER.

PS: Above Items are discussable according to customer's special requirements.