Mbbr HDPE Biofilm Carrier Making Machine Mbbr Filter Media Production Line

QINGDAO TRUSTY PLASTIC MACHINERY CO., LTD.- Product Type:Mbbr Bio Media

- Screw No.:Single-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

- Customized:Customized

Base Info

- Model NO.:SJ-65; SJ-75; SJ-90; SJ-120

- Condition:New

- PLC:Siemens

- Inverter:ABB

- Temperature-Controller:Omron

- Relay:Siemens

- Contactor:Siemens

- Transport Package:Export

- Specification:Trusty

- Trademark:TRUSTY

- Origin:Qingdao

- HS Code:84772090

- Production Capacity:30 Set,Month

Description

Basic Info.

Model NO. SJ-65; SJ-75; SJ-90; SJ-120 Condition New PLC Siemens Inverter ABB Temperature-Controller Omron Relay Siemens Contactor Siemens Transport Package Export Specification Trusty Trademark TRUSTY Origin Qingdao HS Code 84772090 Production Capacity 30 Set/MonthProduct Description

MBBR HDPE bio carrier extrusion making machine

Company Introduction

Qingdao Trusty Plastic Machinery Co., Ltd. is a professional plastic extrusion equipment manufacturer integrating design, research and development, production and sales.

The company's main products are rich, the production technology is mature, and the after-sales service is guaranteed. Products are sold at home and abroad, such as: Brazil, Chile, Mexico, the Philippines, Italy, Russia, Pakistan, Vietnam, India, Algeria, Egypt and other countries.

Our company is located in Qingdao, one of the plastic machinery bases in China, where the railway, sea transportation, aviation and other transportation systems are very complete. And it is one of the regions with rapid economic development in the coastal cities.The advantaged geographical conditions have provided great convenience for the development of the company's trade.

Our company's main products are: PVC door and window profile production line, WPC wood-plastic profile production line, PVC wall panel production line, PVC/PE/PPR pipe production line, PVC/WPC crust foam board production line, PE/PP/PC hollow sheet production line, PVC roof tile production line and PET packing belt production line, etc. According to customers' needs, to achieve diversified processing customization.

Over the years, the company has always adhered to the tenet of "honesty for basis, quality for living, innovation as the theme, and development as the focus", abide by the quality commitment to users, and won the trust of customers.

Machinery brief introduction

Machinery brief introductionBiological PE /HDPE pipe making machine is a production equipment which specialize in producing PE plastic packing, the machine can produce the shape of flower, snow and cross. Our machine is One mould for strips out and with high capacity of 80-100kg/h. Size of the final product Φ25*12mm ,Φ12.5*10mm ,Φ10*7mm ,Φ11*7mm ,Φ12*9mm.

Machinery composition:

| No | Machine Name | Quantity | Remarks |

| 1 | Vacuum Loader | 1set | 300 model |

| 2 | Hopper dyrer | 1set | 75kgs |

| 3 | GB-SJ65/28 Single Screw Extruder | 1set | ABB inverter, Siemens PLC |

| 4 | PE MBBR pipe moulds | 1set | 4Cr13, Six-cavity/ Four-cavity/ Two-cavity |

| 5 | Vacuum cooling tank | 1set | |

| 6 | Water cooling trough | 1set | |

| 7 | Haul off machine | 1set | ABB inverter |

| 8 | Flying cutting machine | 1set | ABB inverter |

| 9 | Storage silo | 1set |

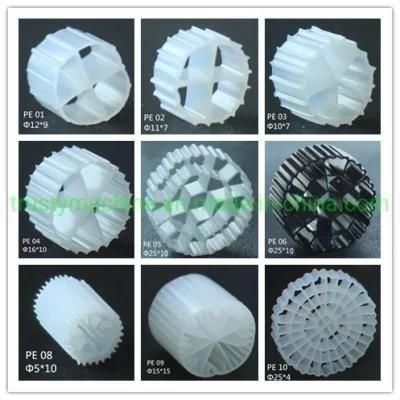

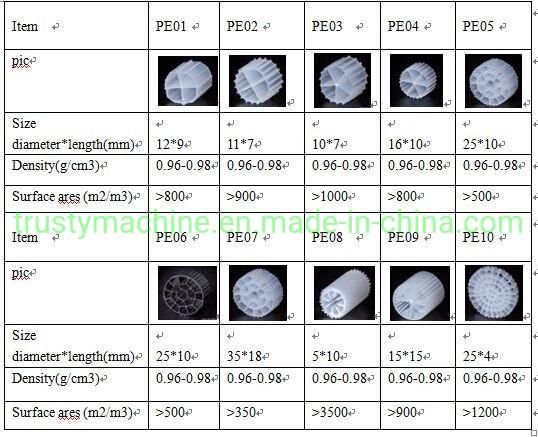

MBBR BIO MEDIA

Product Description. The Moving Bed Bio Media is made of Polyethylene Borealis Quality.

The MBBR Bio Media provided by us is self cleaning and enables excellent surface ratio. The bio-film carrier elements are produced from a material and with a procedure that provided properly stored and used ensures a minimum aging time of 20 years. Our Bio Media can also be used as packing media for water coolers, oil water separators, and de-nitrification systems for polluted fish farms. Due to the use of MBBR Bio Media, the biological treatments get highly effective.

MBBR Filter Media Advantage

Rapid carrier bio film formation mechanism

Super decarburization, ammonia nitrogen removal capacity

Excellent resistance to shock load performance

Flexible way of engineering application

Simple operation and maintenance

Long service life-100% virgin HDPE material.

Deoxidation and phosphorus removal effect is good

MBBR Filter Media Application

The Sewage plant upgrade project , improve the standard and quantity

New sewage treatment project of MBBR and Biological Aerated Filter process

Biochemical treatment of reclaimed water

River regulation denitrification and phosphorus removal

Aquaculture in addition to ammonia nitrogen, water purification

Biological filter media is used for biological deodorization tower

FAQ

1.WHY CHOOSE US

We are the Professional manufacturer to develop the plastic extrusion machines in Qingdao. Machine quality and customer satisfaction is our pursuit.Be sure we have the strength to provide you with quality machines and perfect service.

2.WHAT SERVICES DO WE OFFER?

Pre-sale communication → Design proposal, signature confirmation→

Customized production→ Test machine before shipment →Package &

delivery→ Engineer installation→Training operator → Technical support

3.PAYMENT TERMS:

30% of total amount should be paid by T/T as down payment ,the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C by payment(at sight).

4.DELIVERY CONDITIONS:

4.1 Delivery condition: FOB Qingdao port or CIF destination Port.

4.2 Delivery terms: Within 30-60 working days after receipt of advanced payment, the seller should inform the buyer to do inspection,the seller should finish packing of goods and ready for shipment within 15 working days after the seller receipt the full payment.

5.WARRANTY TERMS

5.1 Warranty period: 12 months, starting from the machine receipt in customer's warehouse

5.2 Seller shall grant: services and spare parts, free-of-charge service throughout the entire equipment during warranty period.

5.3 long life service: the seller should provide long life service for the sold goods, the buyer pay for needed spare parts after the 12months warranty terms.

6.INSPECTION

When the machine finished, the seller should inform the buyer to do inspection before shipment, the seller guaranty good performance of all the sold goods.the seller undertake the material cost for the machine inspection in seller's factory. the buyer should come to seller's factory to do the inspection work, or the buyer could entrust any third party to come to seller's factory to do the inspection work.

7.INSTALLATION AND EQUIPMENT COMMISSIONING:

if the buyer requires, the seller should send technician team to buyer's factory for installation and testing the whole line, and the buyer should undertake the whole food/place and round tickets (airplane, food, hotel, and so on), and pay salary to engineer for 100 usd/day/engineer.