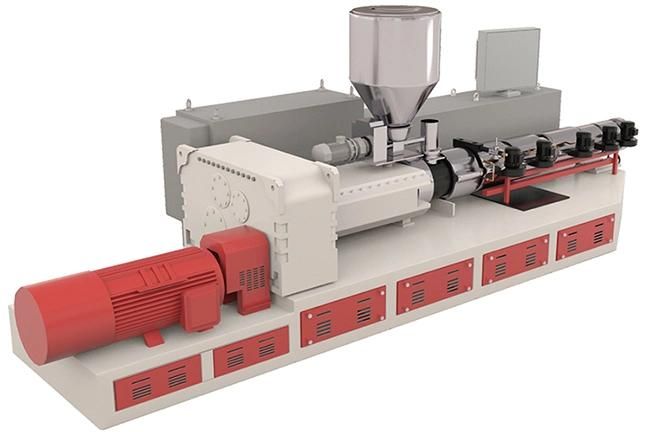

PVC Outdoor Decking Foam Boards Extrusion Machine Line

Wuxi Boyu Plastic Machinery Co., Ltd.- Product Type:PE,PP,PVC

- Screw:Conical Twin Screw

- Automation:Automatic

- Computerized:Digital Smart Program Control

- Certification:CE, ISO9001:2008, UL

- Customized:Customized

Base Info

- Model NO.:SJSZ65,132, SJSZ80,156, SJSZ92,188

- PLC Control:High Tech

- Transport Package:PVC Film or MDF Wooden Case

- Specification:CE SGS

- Trademark:BOYU

- Origin:Jiangsu Wuxi

- Production Capacity:30 Prodcution Lines Per Month

Description

Basic Info.

Model NO. SJSZ65/132, SJSZ80/156, SJSZ92/188 PLC Control High Tech Transport Package PVC Film or MDF Wooden Case Specification CE SGS Trademark BOYU Origin Jiangsu Wuxi Production Capacity 30 Prodcution Lines Per MonthProduct Description

High Capacity PLC Smart Programed ControlWPC Outdoor Decking Extrusion Machine Line

I. Production Line Description :

The machine can produce PE, PP or PVC and wood profile products. These products are mainly applied for making pallets, packing cases, floors, wall decoration materials and other wide applications. The wood powder or plant fiber can be put up to max. 50-75%. This machine can produce the PP, PE, PVC, ABS, PS and etc SJSZ65/132 wpc profile production line including :

II. Equipment List of Production Line

1. SJSZ65/132 Twin Screw Extruder Qty: 1 set

2. Extrusion T-die Qty: 1 set

3.Auto screw feeder Qty: 1 set

4. High speed vacuum Calibration table Qty: 1 set

5. High speed traction machine Qty: 1 set

6. Finish boards cut-to-length machine Qty: 1 set

7. Automatic stacking machine Qty: 1 Unit

III. Main electric component configuration

1) Main Motor: Siemens

2) Low voltage electric components: Schneider

3) Botton/ Knob : Schneider

4) Temperature Controller: Japanese Omron

5) Frequency Inverter made: ABB

6) PLC Control

III. Technical Parameter of Extruders

| No. | Model | SJSZ 65/132 | SJSZ 80/156 | SJSZ 92/188 |

| 01 | Screw Diameters(mm) | 65mm/132mm | 80mm/156mm | 92mm/188mm |

| 02 | L/D Ratio | 22:1/25:1 | 22:1/25:1 | 22:1/25:1 |

| 03 | Capacity (Kg/h) | 160-200 | 250-350 | 400-500 |

| 04 | Main Driving Power(kw) | 37 | 55 | 110 |

| 05 | Heating Powder(Kw) | 4 zones, 20Kw | 5 zones, 38Kw | 6 zones, 54K |

IV. BOYU Service:

"Turn Key" project, including WPC project feasibility analysis, workshop and electric facilities design, machine installation and test, staff training, mould adjust and test, formulation, after-sale service, ect..

BOYU would always supply clients with high-tech, stable-performance, professional property, and exceptional quality WPC machines.

V. Finished products application