PVC Spc Flooring Making Machine / Lvt Vinyl Tile Extrusion Line / WPC Floor Production ...

Qingdao Sanyi Plastic Machinery Co., Ltd.- After-sales Service:Online Support, Spare Parts, Training.

- Warranty:1year

- Type:PVC,Spc,WPC Flooring Board

- Plastic Processed:PVC

- Product Type:Extrusion Molding Machine

- Feeding Mode:One Feed

Base Info

- Assembly Structure:Separate Type Extruder

- Screw:Twin-Screw

- Engagement System:Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Don′t Exhaust

- Automation:Automatic

- Computerized:Computerized

- Raw Material:PVC,CaCO3,Additive

- Flooring Thickness:2-8mm

- Max Capacity:800kgs,H

- Product Name:PVC Spc Floor Tile,Panel,Plank, Board Machine

- Motor:Siemens

- Invertor:Siemens

- Temperature Controller:Omron

- Certification:CE,ISO,TUV

- Installation:Click or Dry Back

- Transport Package:Wooden Package

- Specification:30*4.5*6m

- Trademark:SANYI

- Origin:Qingdao

- HS Code:84772090

- Production Capacity:15set,Month

Description

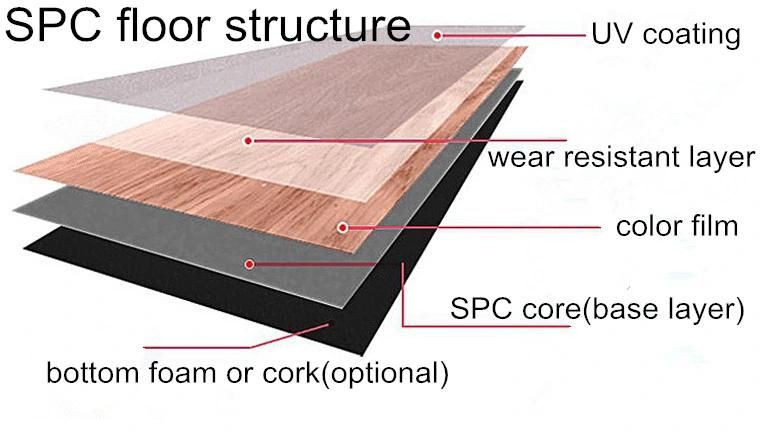

Spc flooring introduction

SPC flooring is the new environmental-friendly resilient ground material,it is very popular in developed countries such as:America and Europe for its excellent performance.

SPC flooring has below advantages:

Spc flooring application

With such excellent features, The SPC vinyl flooring plank/SPC flooring board/pvc flooring tile/pvc flooring plank/luxury vinyl plank flooring /waterproof vinyl plank flooring/

interlockng pvc floor tile covering produced by SPC flooring vinyl plank extruder SPC floor board making machine has a wide range of application:

Department Store,Hotel,Hospital,Restaurant,Bank,Office,Residence.

Certification

Company Profile

Established in 2006, we has been focusing on PVC foam board machine at the beginning.

After more than 10years commitment to this field, we become the most professional PVC foam board machine manufacturer in China.

Now we occupy about 1/3 of domestic market share and our machines have been exported to nearly 30countries/regions in the world.

SPC/WPC flooring machines&PVC artificial marble board machine can be regarded as the new product based on the technic of PVC foam board machine,

thanks to long-term technic accumulation and investment, we become the leader for SPC&WPC flooring machine in China.

Every time We join in important exhibitions,such as:Chinaplas,Domotex Asia,Indiaplast,etc.

and for Chinaplas and Domotex Asia,we always run our machines at the exhibitions!

Package&Delivery

Our Service

Pre-sale service:

To provide information and market research,to provide consultation,to provide many kinds of conveniences and market service,etc.

The main purpose of pre-sales service is to help customers make the project planning and system requirements analysis. Make our products maximum to meet clients' requirements. Also play the greatest overall economic benefits of customers' investment.

After-sale service:

To install products and test products freely for customers.

To provide the formulas and technologies of relevant products and the information of chemical materials manufactories.

To direct technology aspect of relevant use according to customers' requirements

To provide technical training for clients' employees.

To be responsible for maintenance service, door-to-door service under the necessary circumstance.

Technology support:

To provide installation and test for the machine.

To provide formulas and technology of relevant products.

To provide information of chemical material manufactories.

To provide technical training for clients' employees.