Full Automtic PVC WPC Profile Extrusion Machine/WPC PVC Window Door Extrusion Machine/PVC ...

Qingdao Tongsan Plastic Machinery Co., Ltd.- After-sales Service:Professional Engineers Teach Operation

- Warranty:1year

- Product Name:PVC WPC Profile Extrusion Line

- Screw Diameter:51,105

- Suitable Material:PVC WPC

- Cooling Way:Water Cooling

Base Info

- Model NO.:SJMS-51,105

- Heating Way:Electrical Heating

- Transport Package:Wood Block Fixed Steel Wire Reinforcement

- Specification:SJMS-51,105

- Trademark:QINGDAO TONGSAN

- Origin:Qingdao China

- HS Code:84772090

- Production Capacity:24,Years

Description

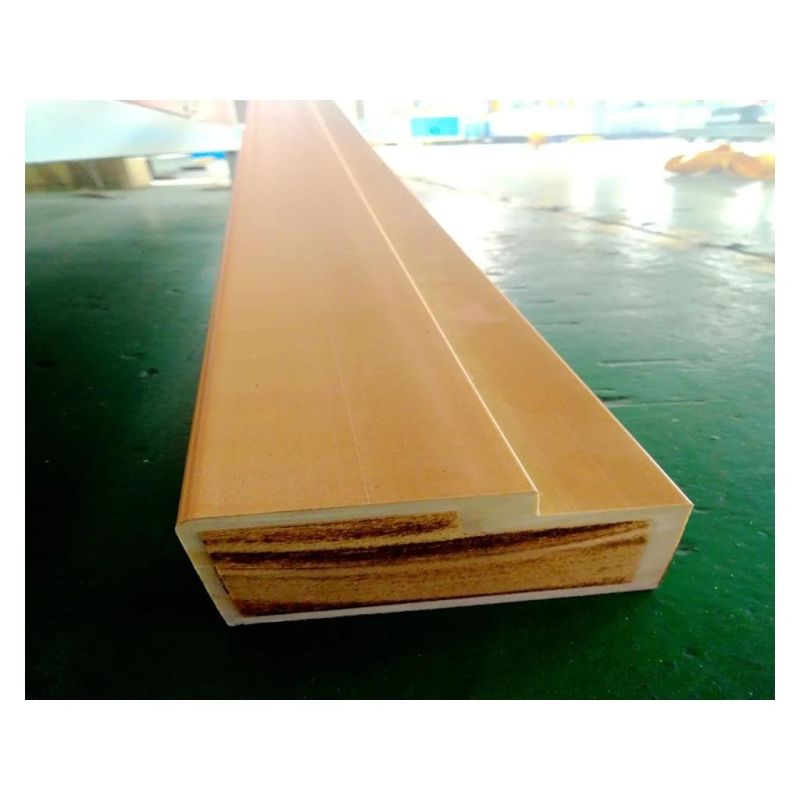

The PE WPC profile extrusion line is suitable for producing the hollow/solid PE WPC profiles. This profile has the advantages of fireproof, waterproof, anticaustic, moistureproof, mothproof, mildewproof and environmentally friendly. It is mainly used for extruding outdoor decorative WPC profiles, such as gardening 1and-scapes, outdoor landscapes, pallets etc.

Combining advanced Canadian technology and the domestic practical situation,our company developed the SJMS series WPC production line.WPC profile extrusion line adopts specially designed screw,barrel,mould and unique WPC craft and formula initiated by our company.The extruder can match with the auxiliary machines and mouls perfectly.The whole extrusion line is of automatic control from the loading to the final discharging.The machines can also be manually adjusted separately.

With the advantages of good plastication,low energy-consumption,high output,excellent performance,long endurance,etc.It can be equipped with relative auxiliary equipment,such as vacuum calibrating platform,haul off machine,cutting machine and material stacker.It is mainly used for extruding outdoor decorative WPC profiles,such as gardening landscapes,outdoor landscapes,palltes,etc.

| SJMS-51/105 | SJMS-65/132 | SJMS-65/132 | SJMS-80/156 | |

| Max.Product Width | 200mm | 250mm | 250mm | 400mm |

| Extruder Capacity | 100kg/h-120kg/h | 150kg/h-180kg/h | 150kg/h-180kg/h | 350kg/h-380kg/h |

| Main Motor Power | 22 kw | 37 kw | 37 kw | 75 kw |

| Vacuum Pump Power | 3 kw | 5.5 kw | 7.5 kw*5.5 kw | 11 kw*7.5 kw |

| Calibrating Platfrom Length | 4000mm | 6000mm | 8000mm | 6000mm |

1.WPC Granulation Machine

After get ready wood powder and recycled PP/PE plastic,The first step is mixing them with chemicals,The use WPC granulation machine to make WPC granules.

PP/PE/PVC wood plastic composite WPC profile making machine

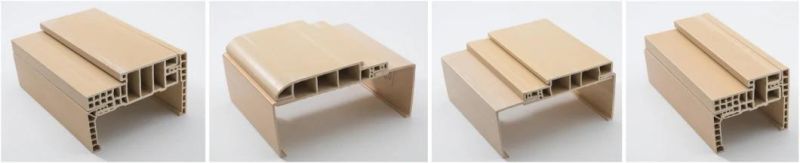

PP/PE wpc profile making machine can continuously produce PP/PE WPC profile. Including PP/PE WPC decking floor, PP/PE WPC outdoor wall panel, PP/PE WPC fence , post and so on.

The customer can also use this line to produce PVC WPC window and door profile by changing the screw and mould.

| Material | Percentage |

| Recycled PP/PE plastic material | 25-30% |

| Wood powder made from wood/rice husk/rice straw/wheat straw/wheat husk | 65-70% |

| Chemicals: PE wax, stearic acid, CaCo3, pigments, coupling agent | 5% |

Company Information

Qingdao Tongsan PLastic Machinery Co.,LTD

Qingdao Tongsan Plastic Machinery Co., LTD is a professional plastic extrusion machines manufacturer which stands by the Jiaozhou Bay. Converged with the national first-class scientific talests, our company is engaged in the study of new- type plastic machines and the conversion of international high-and -new technology. Cooperating with scientific research instifutions and institutions of higher education , we are converting the newest scientific payoffs at top speed. We will supply you the high-performance and high-tech plastic machines, Hollow sheet machine, Corrugated pipe machine, PVC and WPC foam board making machine.

Packaging & Shipping

Fastening of fixed Steel Wire with plastic Film wound Wood Block

Our Services

- We will provide the Feasibility Analysis Report for the wood plastic project.

- We will provide the model selection and technical parameter for wood-plastic machine.

- We will provide the design for the plant and electric powder accounting for the facilities.

- We will provide the design for wood plastic formula according to the product requirement.

- We will provide the technology of wood plastic product surface treatment.

- We will provide technique training for operator.

- We will provide solution for the practical problem during the production.

- We will install and test machine for free.

- We will provide turnkey project to customers.

We look forward to have the opportunity to work together with you in the future.

Alan Jia