PVC Glazed Roof Tiles Extruding Machine PVC Roof Tile Making Machine Plant

Jiangsu Acemien Machinery Co., Ltd.- Product Type:PVC Board

- Board Layers:Multilayer

- Screw No.:Double-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

Base Info

- Customized:Customized

- Condition:New

- Motor Brand:Siemens

- Motor Power:55kw

- Voltage:Customized

- Capacity:350kg-400kg,H

- Transport Package:Film and Wooden Carton

- Specification:SJZ80,156

- Trademark:ACEMIEN

- Origin:China

- Production Capacity:200 Sets ,Year

Description

Basic Info.

Customized Customized Condition New Motor Brand Siemens Motor Power 55kw Voltage Customized Capacity 350kg-400kg/H Transport Package Film and Wooden Carton Specification SJZ80/156 Trademark ACEMIEN Origin China Production Capacity 200 Sets /YearProduct Description

Three layers PVC plastic roofing tile machine

Three layers PVC plastic roofing tile machine

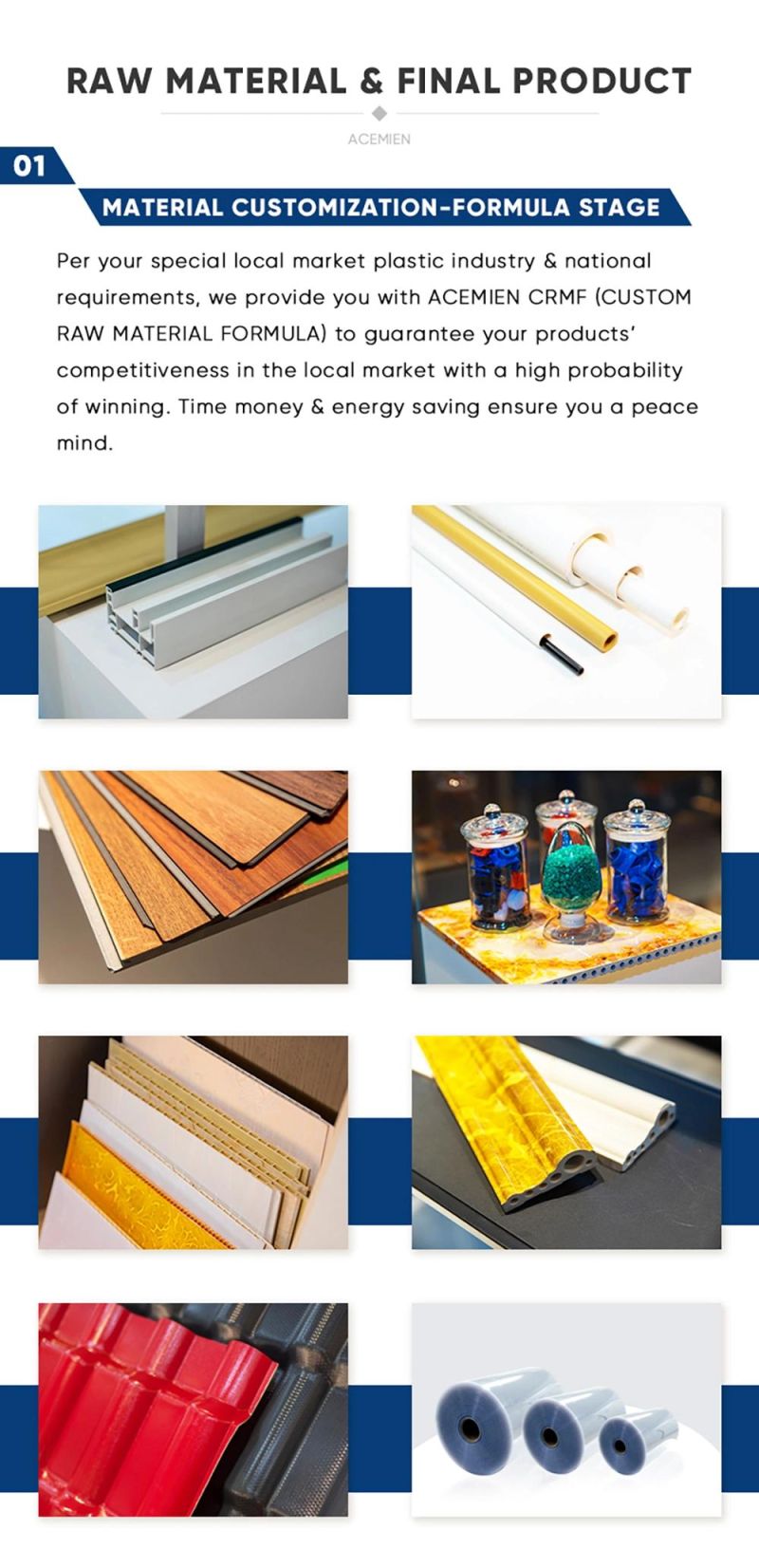

PVC+ASA plastic roof tile machine is designed based on 2 or 3 or 4 layer co-extrusion technology by one-time processing. It is an ideal building material for construction projects with heat insulation requirement. The following is a list of the distinct features of each layer material.

First layer:weather resistant resin is selected as the top layer material to block the solar ultraviolet radiation and reduce the coefficient of heat conductivity. It provides our UPVC roofing material with great durability and chemical corrosion resistance;

Second layer:the middle layer is a special foam structure with heat and sound insulation performances.

Third layer:the bottom layer of our heat insulated UPVC roof sheet adopts modified PVC material to offer optimum strength and rigidity.

| Model no. | Product width(mm) | Product thickness(mm) | Product shape | Extruder power(KW) | Extrusion capacity(kg/h) |

| SJZ80/156 | 840-1130 | 1-4 | Circular/trapezoid | 55 | 350-400 |

| SJZ92/188 | 1130-1340 | 1.5-4 | Circular/trapezoid | 110 | 600-700 |

PVC+ASA Co-extrusion Roof tile making machine

| Machine name | Introduction |

| SJZ80/156 conical twin-screw extruder | Function:make bottom layer Capacity:280-350kg/h Feeder with 2 screws,Feeding smooth and prevent bridging. 2 sets vacuum pots,when clean 1 set pot,do not stop machine running,because other pot also can use,otherwise there is 1 set vacuum pot,it will waste about 10m roof tile when clean pot. Big nut,this can protect the screw and barrel |

| SJ50/30 single screw extruder | Function:make surface layer(ASA/PMMA) With vacuum loader and drying hopper,can make the ASA/PMMA granules dryer. Surface color can according to customers. |

| Extrusion mould and distributor | Function:make ≥ 2 layers roof tile,need the distributor,it can make surface layer and bottom layer together. |

| Embossing roller machine | Function:Embossing pattern, Make the surface more beautiful.The pattern can according to customers. With a type wheel ,customer can type your company name,brand,words etc. |

| Forming machine with trimming device | Function:make roof tile. Type 1: make corrugated tile forming machine with a length counter. type 2: make glazed tile forming machine witha wave counter. |

| Cutter | Function:according to customers needed length,cutting the roof tile.There is a PLC control,it can set 5 data. |

| Ridge tile Oven | Function: put the flat tile to the Oven, when the temperature reach to 150ºC,put the flat tile to the Ridge tile forming machine. |

| Ridge tile Forming machine | Function:according to ridge mould to make the ridge tile. Corrugated ridge:1set Glazed ridge:4sets All kinds of ridge tiles,we can according to customers requirements. Ridge tile mould: Alloy aluminum,surface with polishing process. |

| Auxiliary machine name | Introduction |

| Mixer unit | Function:mixing PVC powder, CaCO3, CPE, Stearic acid , Compound stabilizer ,ACR etc. |

| Crusher | Function:crush the waste roof tile and recycled PVC materials,such as PVC pipe,sheet,profile etc. |

| Pulverizer | Function:grind the PVC flakes to powder. |

Product info:

| Raw material & formulation | Bottom layer: PVC powder, CaCO3, CPE, PE-WAX, Stearic acid, Compound stabilizer, ACR, paraffin. Surface layer: ASA granule |

| Description final product | Glazed tile: Width:880mm;1040mm Thickness: 1.5~3mm; Main tile:1set Ridge tile:4sets Corrugated tile: Width:920mm;1130mm Thickness: 1.5~3mm; Main tile:1set Ridge tile:1set All kinds of ridges,customers can choose. |