PC/PP Hollow Grid Sheet/Profile Extrusion Machine Production Line

Qingdao Suke Machinery Co., Ltd.- Product Type:PE Board

- Board Layers:Single Plate

- Screw No.:Single-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

Base Info

- Model NO.:SJ120 x33

- Customized:Customized

- Condition:New

- Brand:Suke

- Material of Roller Calender:Seamless Steel of Good Quality

- Mould for Sheet/Board:T Type

- Button:Schneider

- Inverter:ABB

- Intelligent Temperature Controller:Omron

- Warranty:12monthes

- After Sale Service:Life Long with Professional After Sale Team

- Machine Color:as Request

- Operator:2-4 Per Line

- Transport Package:According to Your Requirement

- Specification:ISO9000 CE

- Trademark:suke

- Origin:Qingdao, China

- HS Code:84775900

- Production Capacity:25sets,Year

Description

Basic Info.

Model NO. SJ120 x33 Customized Customized Condition New Brand Suke Material of Roller Calender Seamless Steel of Good Quality Mould for Sheet/Board T Type Button Schneider Inverter ABB Intelligent Temperature Controller Omron Warranty 12monthes After Sale Service Life Long with Professional After Sale Team Machine Color as Request Operator 2-4 Per Line Transport Package According to Your Requirement Specification ISO9000 CE Trademark suke Origin Qingdao, China HS Code 84775900 Production Capacity 25sets/YearProduct Description

PC/PP Hollow Grid Sheet/Profile Extrusion Machine Production Line

MACHINE INTRODUCTION

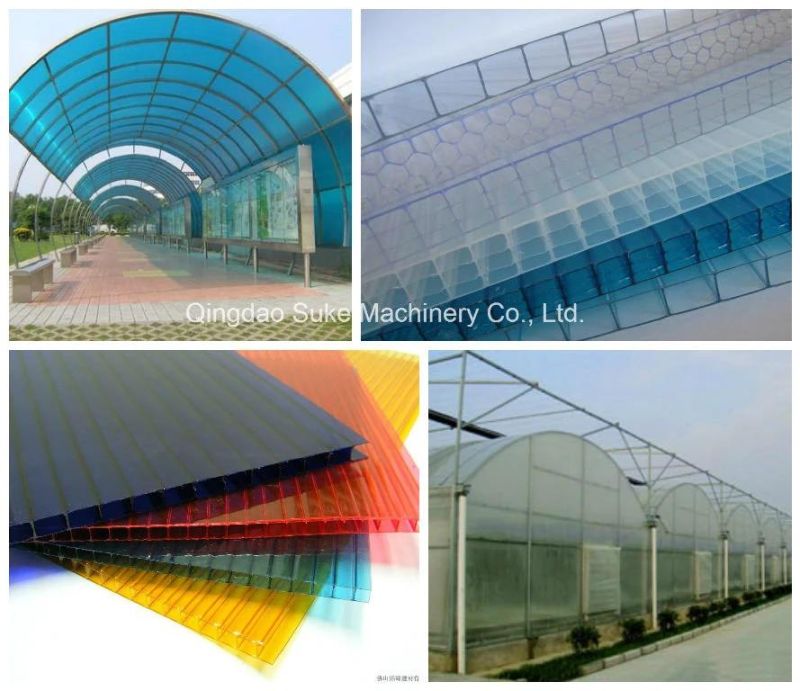

The PC hollow sheet production line is the special equipment for extruding PC hollow grid board. With smooth mooth and clean surface, beautiful appearance and pressure resistance. Plastic Hollow Grid Board Extrusion Line is widely used in construction, packaging and decoration industries etc.The technology of hollow sheet die with co-extrusion feed block to get UV+PC+UV, UV+PC hollow sheet can save 30% UV on the surface.

THIS LINE IS CONSISTE OF :

This extrusion line consists of single screw extruder, melt-pump, hydraulic filter exchanging unit, hollow sheet die head, vacuum calibrating table, first haul off machine, oven, corona treating unit, cooling table, second haul off machine, trimming and length-settled cutting units and stacker etc

MACHINE DETAILS:

xtruder model | Φ100 | Φ120 |

| Product width | 1300mm | 2100mm |

| Product thickness | 2-10mm | 2-10mm |

| Motor power | 110kw | 132kw |

| Papacity | 250-300kg/h | 400-450kg/h |

TRADE TERMS

- Payment Term: 30% for prepayment by T/T, 70% for balanced payment by T/T, or L/C can be acceptable

- Delivery Time: 40 days after receipt of prepayment.

- Packing Method: Packing film or wooden case

- Guaranteed Time: 12 months

MACHINERUNNING TEST AND AFTER SERVICE

- When machine finished, we will invited client come to our factory to check the machine and do the machine test. If machine is ok, then client pay for the balance. And inspect machine load the container.

- When machine arrives client's factory, if client needs, we will send 1-2 engineer to client's factory do the machine installation and running test, and also train the local worker how to operate and maintain the machine. It is chargeable.

- If have any question or problem on machine operation or maintain, welcome to contact to us by email or calling. We stand by 24 hours.

COMPANY SHOW