Post Consumer LDPE/BOPP/LLDPE/HDPE/PA/ABS/EVA/PS/EPS Film/PP Woven Bags/Non ...

ZHANGJIAGANG RETECH MACHINERY CO., LTD.- After-sales Service:Yes

- Warranty:1 Year

- Material Processed:Film

- Plastic Type:PE

- Screw:Single-Screw

- Automation:Automation

Base Info

- Model NO.:RCSJ RCDJ

- Computerized:Computerized

- Certification:ISO9001:2008, CE

- Capacity Range:100-1000kg,H

- Feeding Way:Compactor

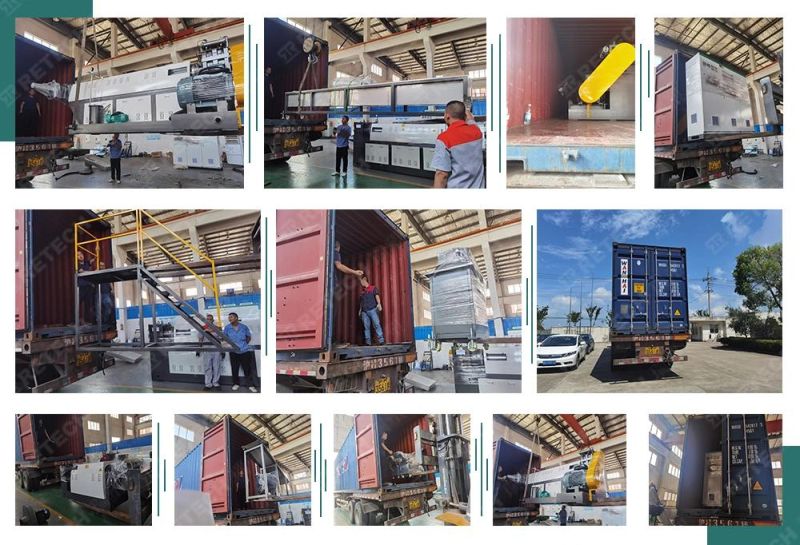

- Transport Package:by Sea

- Specification:TSSJ100~200 THSJ65~220 TCSJ85~180 TCDJ85~180

- Trademark:RETECH

- Origin:China

- HS Code:8477201000

- Production Capacity:100 Sets Per Year

Description

Overview

Product Description

Customer requirements →Scheme designed →confirmed by customers →order fixed →manufacturing →trial running in our factory →confirmed by customers →shipped →engineer available overseas →whole life after sales services

How to choose single stage or double stage?

Common:

The same feature between single and double stage pelletizing machine is they can all extrusion the plastics. They can all recycle the waste plastics into plastic granules.

Difference:

* Single stage granulating line is with one stage, double stages granulating line is with two stages extruders.

* Single stage granulaying machine is usually to process clean and dry plastics, double stages granulating machine is usually to process dirt and wet plastics.(Mositure less then 8%)

*You can choose single or double stages according to the material is dirty or clean. Normally, double stage with 2 filtrations system will stop more impurities.

*In all, we can customzied your machines according to different situations.

Detailed Photos

Our Advantages

360°services:

Customer requirements →Scheme designed →confirmed by customers →order fixed →manufacturing →trial running in our factory →confirmed by customers →shipped →engineer available overseas →whole life after sales services

How to choose single stage or double stage?

Common:

The same feature between single and double stage pelletizing machine is they can all extrusion the plastics. They can all recycle the waste plastics into plastic granules.

Difference:

* Single stage granulating line is with one stage, double stages granulating line is with two stages extruders.

* Single stage granulaying machine is usually to process clean and dry plastics, double stages granulating machine is usually to process dirt and wet plastics.(Mositure less then 8%)

*You can choose single or double stages according to the material is dirty or clean. Normally, double stage with 2 filtrations system will stop more impurities.

*In all, we can customzied your machines according to different situations.