Full-Automatic Waste Plastic Recycling Machine/Small PE PP Washing Line

Sichuan Union Technology Co., Ltd.- Type:Sheet Extruder

- Plastic Processed:PP

- Product Type:PP Straps

- Feeding Mode:One Feed

- Assembly Structure:Separate Type Extruder

- Screw:Single-Screw

Base Info

- Model NO.:YZJLQD

- Engagement System:Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Don′t Exhaust

- Automation:Automatic

- Computerized:Computerized

- Voltage:380V 50Hz 3phase(Customized)

- Power:120kw

- Power Consumption:About 35kw,H

- Raw Material:Origin or Good Waste PP Plastic

- Thickness of Strapping:0.5-1.5mm

- Width of Strapping:5-19mm

- Max Capacity:50-200kg,H

- Certification:Ce ISO9001

- The Brand of Motor and Inverter:Siemens or Teco or Else

- Transport Package:Plymood

- Specification:38mx2.5mx2.2m

- Trademark:YZJ

- Origin:Sichuan

- HS Code:8477800000

- Production Capacity:5sets

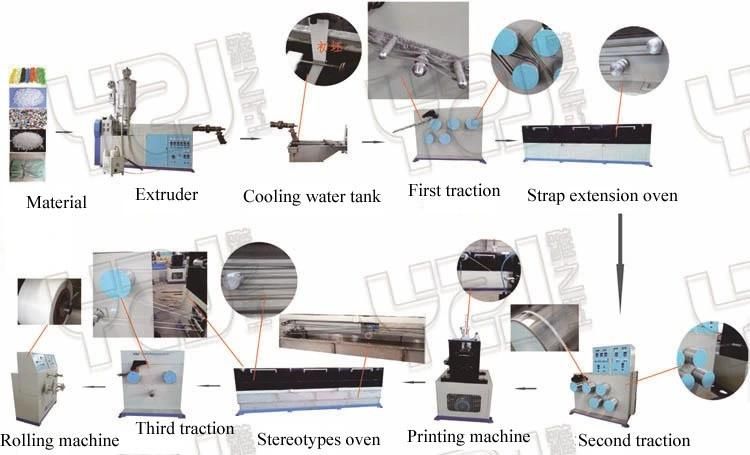

Description

Engine

Main performance parameters

The parameters of PP strap 12006

Main Features

1) PLC control system of the pp strap manufacturing machine making the operation more easy and lower request;

2) Reciprocating super-long distance low-temperature stretching, great stretching times, good rigidity of finished band;

3) Light heat setting unit, differential speed traction design, internal stress may be removed to the maximum extent;

4) Organic combination of the 3rd stretching unit and embossing mechanism, scientific structure, advanced configuration;

5) Self-circulating wind heat warming system of the pp strap manufacturing machine, energy saving ;

6) High-accuracy good-quality screw, large extrusion capacity, constant extrusion pressure.

Certifications

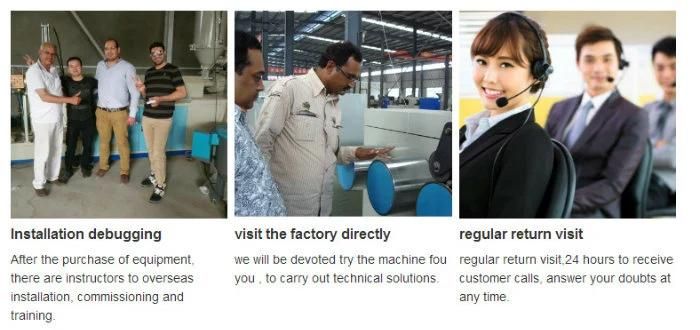

Our service

After-sales service

1.We provide one-year warranty guarantee for all the machines. We supply long term spare parts for every customer and 24 hours technical suport by email, calling and door to door service;

2.We run machines in our factory before delivery. Clients check machines running in our factory, and when machines arrive in Client's factory, we will send our engineer to run machines in client's factory too.

3.We provide service manual and maintenance instruction of main electric appliance,usage manual of equipment.

4.We also supply installation drawing of water, electricity, gas of equipment.

Shipping&delivery