Automatic Pert Pipe Coiler, Automatic Pert Pipe Winder, PE-Rt Tube Making Machine

Weifang Kaide Plastics Machinery Co., Ltd.- Type:Pipe Extruder

- Plastic Processed:PE

- Product Type:Granulating Extruder

- Feeding Mode:One Feed

- Assembly Structure:Separate Type Extruder

- Screw:Single-Screw

Base Info

- Model NO.:PERT pipe machine

- Engagement System:Non-Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Don′t Exhaust

- Automation:Automatic

- Computerized:Computerized

- Pipe Diameter:16mm-32mm

- Line Speed:35m,Min,60m,Min

- Engineer Service:Engineer Was Available for Overseas Service

- Control System:Siemens PLC Control System

- Electrics:Schneider

- Inverter:ABB Brand

- Sensor:Autunics

- Bearings:SKF

- Coiling System:Automatic Coiler

- Strapping System:Auto Strapping Uni

- Transport Package:1X40 Gp Container

- Specification:60m,min line speed PERT

- Trademark:kaide

- Origin:China

- HS Code:8477800000

- Production Capacity:200 Sets Per Year

Description

Basic Info.

Model NO. PERT pipe machine Engagement System Non-Intermeshing Screw Channel Structure Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Pipe Diameter 16mm-32mm Line Speed 35m/Min,60m/Min Engineer Service Engineer Was Available for Overseas Service Control System Siemens PLC Control System Electrics Schneider Inverter ABB Brand Sensor Autunics Bearings SKF Coiling System Automatic Coiler Strapping System Auto Strapping Uni Transport Package 1X40 Gp Container Specification 60m/min line speed PERT Trademark kaide Origin China HS Code 8477800000 Production Capacity 200 Sets Per YearProduct Description

High speed PE-RT pipe line adopts specially designed high efficient five-section type screw and barrel, which are our company independent design, with completely independent intellectual property rights.

High speed PE-RT pipe line adopts specially designed high efficient five-section type screw and barrel, which are our company independent design, with completely independent intellectual property rights.

Tehnical Data

| Line Model | Screw Diameter | L/D | Production Speed | Nominal Power |

| SJ-75 | Ф75mm | 36:1 | 50m/min | 155KW |

| SJ-60 | Ф60mm | 36:1 | 35m/min | 104KW |

| SJ-80 | Ф80mm | 33:1 | 25m/min | 112KW |

| SJ-65 | Ф65mm | 33:1 | 15m/min | 76KW |

Gravimeter System

High precise Gravimeter control system of is applied in this PE-RT pipe production line.

(1 )It is used for measuring & calculating and precise control of pipe weight per meter and its extrusion output, to realize the constancy of pipe weight.

(2) The application of this system can shorten the start-up time, improve the produced pipe quality, and save raw material.

Die head

(1)The specially designed spiral pressure-storage die head of this PE-RT pipe making machine effectively overcomes the instantaneous fluctuation of extrusion pressure,

(2)Realizing high speed and constant pressure extrusion of materials.

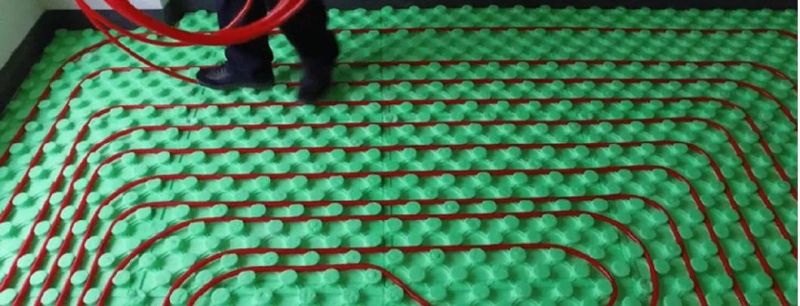

Automatic Coiler

The automatic double working position pipe coiler of this PERT pipe machinery can realize automatic reel changing according to set length,automatic cutting and coiling.

(1) Using servo controlled high precise traversing device and tension control device.

(2) SIEMENS PLC independent control.

Siemens PLC control system

(1)The production line to make PERT pipe adopts original new generation PLC control system.

(2) Adopting Multi-point closed loop control system, ensuring high speed synchronous control and reliable operating.

Other Functions

Added some auxiliary machine, the PERT pipe production line can produce three layer or five layer EVOH/PERT pipe.

PERT Pipe Application Introduction

Pert pipe, or heat-resistant polyethylene PERT pipe, is the abbreviation of polyethylene of raised temperature resistance. It is a kind of non crosslinked polyethylene that can be used in hot water pipes. Pert is a kind of medium density polyethylene with stable mechanical properties Because of its unique structure of ethylene main chain and octene short branch chain, it has excellent toughness, stress cracking resistance, low temperature impact resistance, long-term water pressure resistance and heat creep resistance of octene. Pert pipe adopts two kinds of hot-melt process: hot-melt socket welding process and hot-melt butt welding process.

Application fields of PERT pipes and fittings

1. Cold and hot water pipe

(1) Excellent low temperature brittleness resistance. Because PERT is polyethylene with similar molecular structure, it has better low temperature brittleness than PPR. The low temperature brittleness of PPR is + 5 ºC, while that of PERT is - 40 ºC.

(2) The high temperature resistance of PPR is 70 ºC and pert is 90 ºC.

(3) The pressure bearing performance is superior. Under the same service conditions, because PERT pipe has higher design pressure and better pressure bearing capacity, under the same pressure bearing conditions, PERT pipe has thinner wall thickness, larger diameter and more sufficient flow.

(4) The flexibility of the product is good, and it can be connected in a variety of ways, which makes the construction of the product more convenient and time-saving.

For More Information, please feel free to contact us !