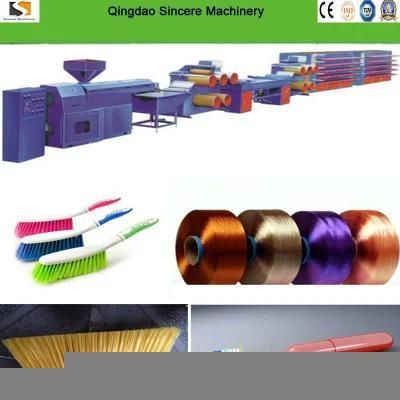

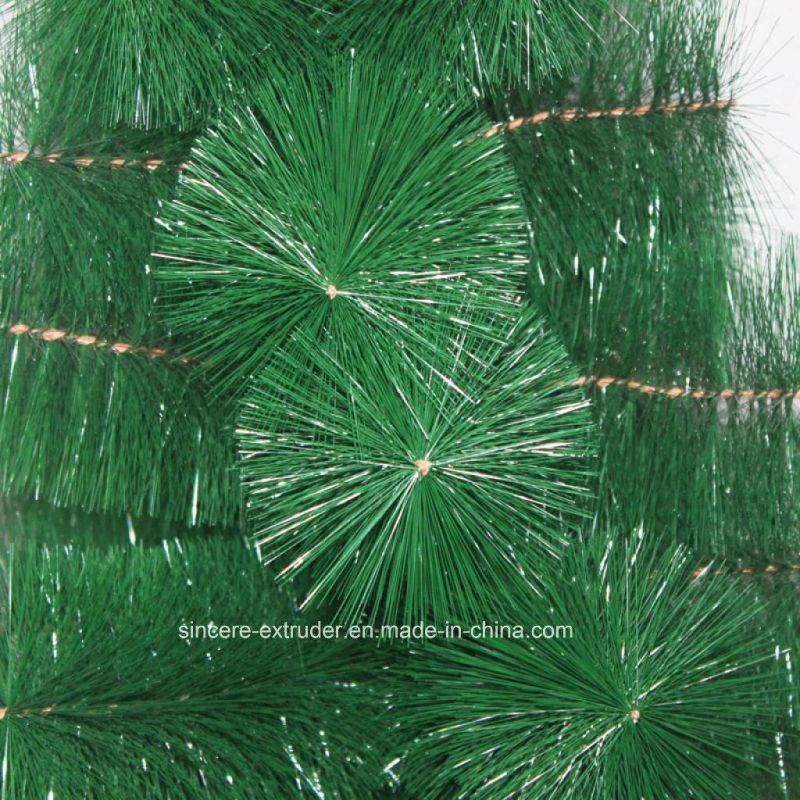

Artificial Pine Needles Extrusion Manufacturing Machinery

Qingdao Sincere Machinery Co., Ltd.- Product Type:Pet PP Plastic Broom Brush Monofilament

- Screw No.:Single Screw or Parallel Twin Screw Extruder

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008, TUV

- Customized:Customized

Base Info

- Model NO.:SJ55, SJ65, SJ75, SJ90

- Condition:New, Under The Order

- Warranty:1year

- Sheet Types:Sheet Surface Matte or Smooth, Vacuum Forming Shee

- Delivery Conditions:Fob CIF CIP

- Processing Period:40 Days

- Delivery Period:30days

- After-Sales Service:Send Engineers Install and Test Machine

- Technical Support:Permanent

- Line Diamision:30m*3*3m

- Line Weight:8-20t

- Output:60-300kg H

- Transport Package:Stretch Film and Wooden Pallet, Wooden Packing

- Specification:Monofilament Diameter: 0.04-0.07mm Number: 500

- Trademark:Sincere Machinery

- Origin:Qingdao, China

- HS Code:8477209000

- Production Capacity:50 Sets Year

Description

Basic Info.

Model NO. SJ55, SJ65, SJ75, SJ90 Condition New, Under The Order Warranty 1year Sheet Types Sheet Surface Matte or Smooth, Vacuum Forming Shee Delivery Conditions Fob CIF CIP Processing Period 40 Days Delivery Period 30days After-Sales Service Send Engineers Install and Test Machine Technical Support Permanent Line Diamision 30m*3*3m Line Weight 8-20t Output 60-300kgH Transport Package Stretch Film and Wooden Pallet, Wooden Packing Specification Monofilament Diameter: 0.04-0.07mm Number: 500 Trademark Sincere Machinery Origin Qingdao, China HS Code 8477209000 Production Capacity 50 SetsYearProduct Description

PET PP Plastic Broom brush Monofilament Extruder Machine.

1.The use:

This extrusion line is mainly used to produce broom monofilament silk, toothbrush silk, brush wire, fishing wire, rope wire etc. from polyethylene, polypropylene, PET polyester.

2.Components:

It consists of dehumidifying and crystallizing system, extruder, screen changer, Meter pump, mold, haul-off, oven, and winder, etc.

3.Production Process:

Material→ Dehumidifying and Crystallizing → Extruding → Filter→ Metering→ Mold → Cooling→ Haul-off →Oven Heating→ Haul-off→ Oven heating→ Haul-off → Glazing → Shaping → Haul-off→ Winding

4.Features:

1. With 100% bottle flakes material, or mixed with PET/PP raw material

2. New technology, hot wind cycles to dry, increase the viscosity of the bottle flakes material; secondary stretching, increase the tensile strength and elongation, the belt tension reaches more than 10000N

3. Precise and energy saving temperature control system, power saving, low noise, low input and high yield

5.Application:

With 100% bottle flakes recycled material, to produce PET or PP monofilament, like broom filament, zipper filament, Christmas tree filament, broom monofilament silk, toothbrush silk, brush wire, fishing wire, rope wire, fishing net wire, construction fence wire, etc.

PET Broom Monofilament Extrusion Machine, PET Zipper Monofilament Machine,

PET Pine Needle Filament Extrusion Machine, PET Fishing Net Wire Equipment

PET Construction Fence Wire Equipment, toothbrush silk production machine, brush wire produce line, fishing wire extrusion line, rope wire extrusion machines.

PET broom/brush monofilament production line.

Ekaterina

+8615726275773