Side Force Feeder PP PE Soft Film HDPE Rigid Flakes Recycling Granulating Pelletizing Line

ZHANGJIAGANG RETECH MACHINERY CO., LTD.- After-sales Service:Yes

- Warranty:1 Year

- Material Processed:Film

- Plastic Type:HDPE LDPE LLDPE PP Film

- Screw:Single-Screw

- Automation:Automation

Base Info

- Model NO.:RCSJ RCDJ

- Computerized:Customized

- Certification:ISO9001:2008, CE

- Color:Could Be Customized

- Type of Extruder:Deagassing Tyep

- After-Sale Service:Engineers Available to Service Machinery Overseas

- Stage:Doulbe or Single or Multi

- Feeder Type:Force Feeder or Compactor

- Transport Package:Wrap Film

- Specification:TSSJ100~200 THSJ65~220 TCSJ85~180 TCDJ85~180

- Trademark:RETECH

- Origin:China

- HS Code:8477201000

- Production Capacity:300~3000kg,H

Description

Basic Info.

Model NO. RCSJ RCDJ Computerized Customized Certification ISO9001:2008, CE Color Could Be Customized Type of Extruder Deagassing Tyep After-Sale Service Engineers Available to Service Machinery Overseas Stage Doulbe or Single or Multi Feeder Type Force Feeder or Compactor Transport Package Wrap Film Specification TSSJ100~200 THSJ65~220 TCSJ85~180 TCDJ85~180 Trademark RETECH Origin China HS Code 8477201000 Production Capacity 300~3000kg/HProduct Description

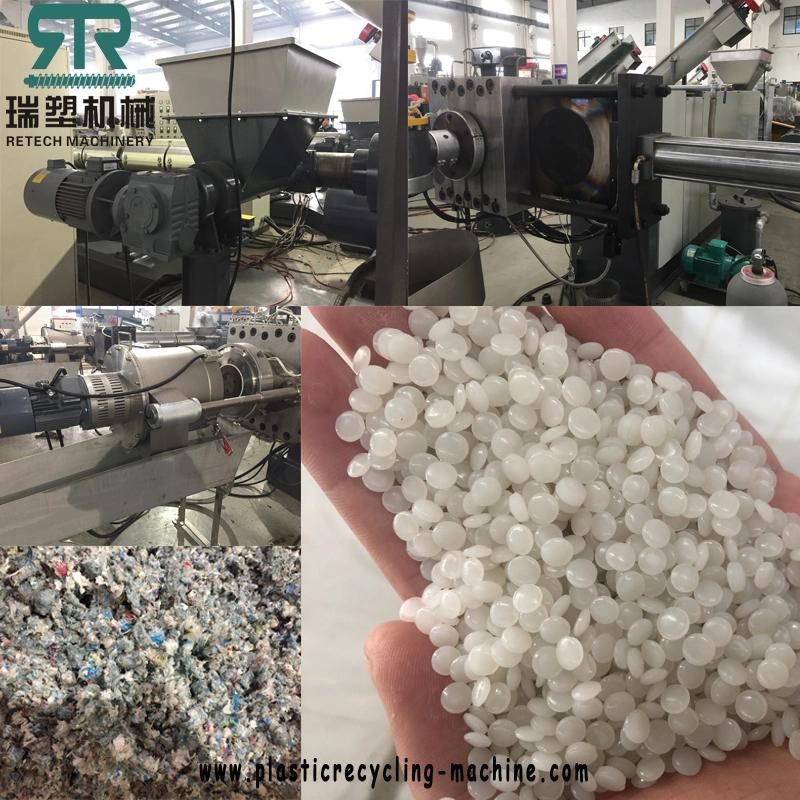

Side Force Feeder PP PE Soft Film Rigid Flakes recycling pelletizing line

1. Introduction and Application Side Force Feeder PP PE Soft Film HDPE Rigid Flakes Recycling Granulating Pelletizing Line

1 Applicable plastic materials: PE, HDPE, LDPE, PP, etc.

2 Material shapes: rigid flakes, agglomerated film, soft films

3 Note: depending on different material properties, various downstream equipments are needed.

4 Better degassing and better quality with two stages

2.Features Side Force Feeder PP PE Soft Film HDPE Rigid Flakes Recycling Granulating Pelletizing Line

1 Remove the volatile material such as air, water or chemical material by strong vacuum degassing system

2 Twice filtering, guarantee the purity of the pellets

3 Complete auxiliary equipments, guarantee the machine running for 24 hours without stopping.

4 The moisture of pellets: below 1%

3.Side Force Feeding Type Pelletizing Line

| Model | Screw Diameter(mm) | Main Motor Power(kw) | Side Force Feeder Motor Power(kw) | Capacity(kg/h) |

| TCSJ100/30 | Φ100 | 55-75 | 5.5 | 150-200 |

| TCSJ120/30 | Φ120 | 75-90 | 7.5-11 | 200-350 |

| TCSJ130/30 | Φ130 | 90-110 | 11 | 300-400 |

| TCSJ150/28 | Φ150 | 132-160 | 15 | 350-500 |

| TCSJ160/28 | Φ160 | 160-185 | 15 | 450-550 |

| TCSJ180/25 | Φ180 | 185-200 | 18.5 | 600-800 |

| TCSJ200/25 | Φ200 | 200-250 | 22 | 800-1000 |

PE film pelletizing machine/PP PE waste film woven bag pelletizer/PE PP pelletizing machine/PE film granulating line/ PE PP hard rigid flakes recycling pelletizing line

With proper extruding moulds, screws and auxiliaries machine, plastic pelletizing machine can used for granulating many kind of raw material such as PE, PP, XPS EPS and so on. We are leading of PE PP film recycling pelletizing machine in china and we can supply our customer best machine with the best price.

Feeding type for PE /PP pelletizing machine:

1. Hopper feeder (suitable for agglomerated material, hard scrap material)

2. With a separate agglomerator (suitable for film, bag etc)

3. Compactor (suitable for bundled big size film bag)

4. Reel feeder (suitable for film roller)

5. Side force feeder(suitable for film scraps, hard material scraps)

6. Vertical force feeder (suitable for film scrap and hard material scrap)

Pelletizing cutting type for PE film pelletizing machine:

1. Water ring cutting

2. Noodle string strand cutting

Extruder type for PE film pelletizing machine:

1. Single stage

2. Double (two)stage

Welcome to send inquiry for more detailed machine specification and price, I will send you competitive offer very soon!

Welcome to add me for instant talk and better service!

Thanks!

360°services:

Customer requirements →Scheme designed →confirmed by customers →order fixed →manufacturing →trial running in our factory →confirmed by customers →shipped →engineer available overseas →whole life after sales services

Package and Loading:

Contacts:

RETECH Machinery is an experienced and professional manufacturing for series plastic washing recycling machine/ plastic granulating recycling machine including ET bottle recycling machines, PE PP film recycling machines, plastic PE PP PS ABS PET PC PVC LD HD LLD BOPP granulating line, water treatment for the waste water from washing line, and auxiliary equipment for plastic recycling....

If you are interesting more details of our products, please contact with us no hesitation!