Manufacturing Plastic Profile Making Machine PVC Corner Bead Extrusion Making Machinery

Suzhou Midtech Industry Co., Ltd.- Product Type:PVC Profile

- Screw:Double-Screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

- Customized:Customized

Base Info

- Inverter:ABB

- Contactor:Schenider

- Motor:Weg

- Speed:6m,Min

- Cavities:6-10

- Tempertaure Control:Rkc

- Extruder:Sj65,25 Extruder

- Screw/Barrel:Bimetallic

- Gearbox:Guomao

- Printing Machine:3 Color Printing Machine

- Mould:6 Cavities

- Transport Package:Standard Export Packing

- Specification:Electric

- Trademark:Midtech

- Origin:China

- HS Code:84778000

- Production Capacity:10 Sets, One Year

Description

Basic Info.

Inverter ABB Contactor Schenider Motor Weg Speed 6m/Min Cavities 6-10 Tempertaure Control Rkc Extruder Sj65/25 Extruder Screw/Barrel Bimetallic Gearbox Guomao Printing Machine 3 Color Printing Machine Mould 6 Cavities Transport Package Standard Export Packing Specification Electric Trademark Midtech Origin China HS Code 84778000 Production Capacity 10 Sets/ One YearProduct Description

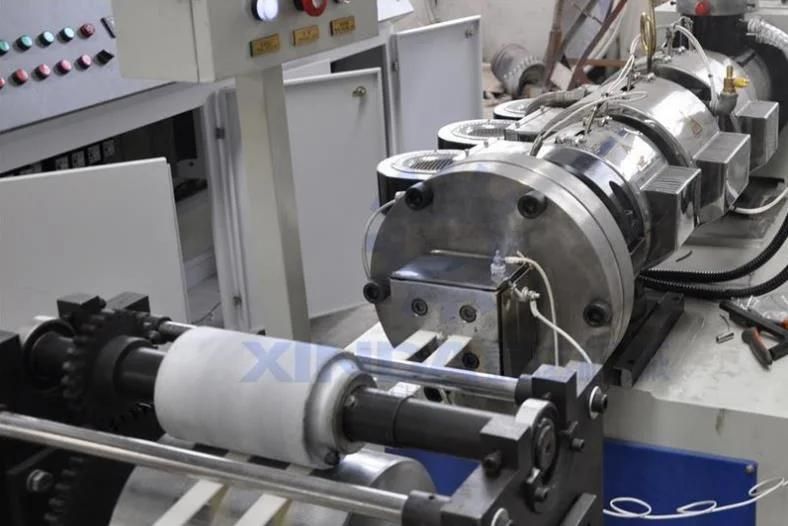

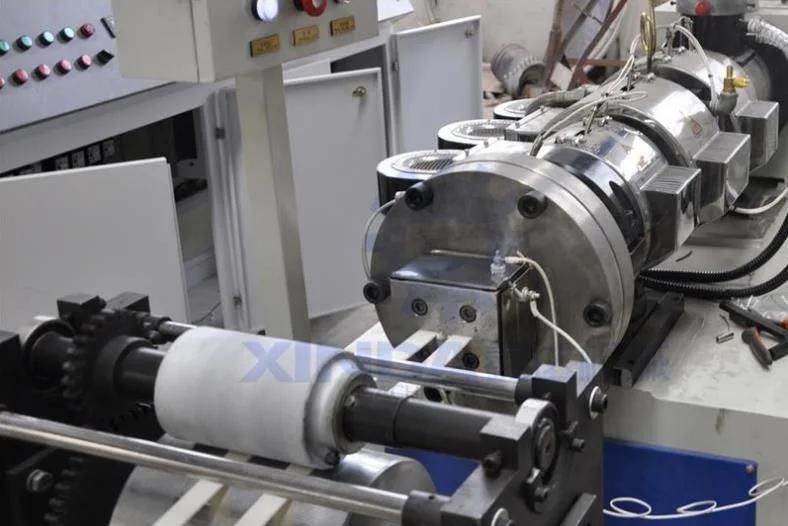

Plastic PVC corner bend/Edge banding/band sheet profile making machine

The main component of PVC edge-sealing strip is polyvinyl chloride, which is made by mixing, calendering and vacuum suction.

Products are widely used in furniture, office, kitchenware, teaching equipment, civil laboratories and so on.

Through market combination and our technology innovation, Midtech pleased to provide- High capacity (Max 6 cavities)

- Low material cost (Cheap formulation)

- High lineal speed (6-8m/min),

- Colorful surface (Hot stamp or mix color master batch)

Depend on different capacity, it have two type of extrusion: Sheet with slitting cutting and Profile extrusion line

Process Flows:

Plastic(PVC) + additives

high speed heating mixer --- PVC extruder-- Die--- Calibration table---haul off--- pneumatic cutter --- stacker

Technical Parameter

| Feeder | • To feed material into extruder; |

| Extruder | •World famous brand electrical component: Siemens,Schneider, ABB etc; • High torque gearbox with adopts NSK/SKF bearing; • Siemens/WEG original motor achieved global after service; • Bimetallic screw and barrel; • Intelligent PLC controlling system with human-friendly interface. |

| Die head | • 3Cr13/3Cr17 material • Straight extrusion sheet die |

| Calibration table | • Calibration mould • Length: 6000mm |

| Haul off | • Upper/lower caterpillar driven separately and speed control by inverter |

| Cutter | • Pneumatic cutter |

| Winder | |

| Printing machine | • Decorative pattern and different color |

And with different capacity, it will different extrusion model:

| Model | Screw diameter | Capacity | Power | Material |

| MTE45 | 45 | 20-50KG/H | 7.5-11kw | Granule |

| MTE50 | 50 | 30-70kg/h | 11-22kw | Granule |

| MTE55 | 55 | 40-80 | 15-30kw | Granule |

| MTE65 | 65 | 60-100kg/h | 22-37kw | Granule |

| YSJSZ45 | 45/100 | 50-80kg/h | 15kw | Powder |

| YSJSZ51 | 51/105 | 60-100kg/h | 18.5kw | Powder |