PVC Crust/Celuka Furniture Foam Board Extrusion Production Line Plastic Machine ...

Qingdao Suke Machinery Co., Ltd.- Product Type:PVC Board

- Board Layers:Single Plate

- Screw No.:Single-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

Base Info

- Model NO.:SJSZ80x156

- Customized:Customized

- Condition:New

- Matertial:Stainless Steel

- Power Supply:380V Three Phase

- Control System:PLC Control System

- Button:Schneider

- Inverter:ABB

- Intelligent Temperature Controller:Omron From Japan

- After Sale Service:Life Long with Professional After Sale Team

- Machine Color:as Request

- Operator:2-4 Per Line

- Extruder Type:Conical Twin Screw Extruder

- Transport Package:According to Your Requirement

- Specification:ISO9000 CE

- Trademark:SUKE

- Origin:Qingdao, China

- HS Code:847780000

- Production Capacity:40pics,Year

Description

Basic Info.

Model NO. SJSZ80x156 Customized Customized Condition New Matertial Stainless Steel Power Supply 380V Three Phase Control System PLC Control System Button Schneider Inverter ABB Intelligent Temperature Controller Omron From Japan After Sale Service Life Long with Professional After Sale Team Machine Color as Request Operator 2-4 Per Line Extruder Type Conical Twin Screw Extruder Transport Package According to Your Requirement Specification ISO9000 CE Trademark SUKE Origin Qingdao, China HS Code 847780000 Production Capacity 40pics/YearProduct Description

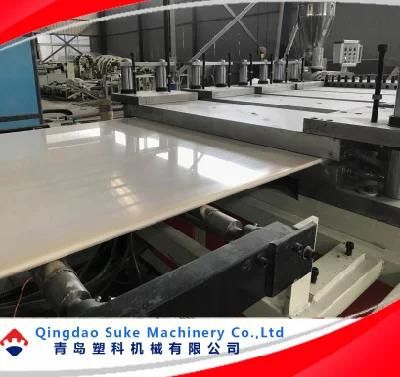

PVC Crust/Celuka Furniture Foam Board Extrusion Production LIne Plastic Machine Manufacturer

MACHINE INTRODUCTION:

Certificate: CE, ISO9001:2008, SGS,

Brand Name: SUKE

Output of PVC Board: 600kg/h

Dimension of PVC Foam Board:1220*2440*(3-30)mm

Plastic Processed: PVC and WPC

Application of Finished Board: Formwork, Furniture board, cabinet board, building template, advertisement board, wall panels, floor, roof, car and boat board etc.

Screw Design: Double-screw

Model Number: SYSJ80/156

Density of finished board: 0.37-0.85

Voltage: 380-440V

Main Motor Power: 90kw

PRODUCT DETAILS"

| Width of Sheet | 400-2500(mm) |

| Thickness of Sheet | 0.2-50(mm) |

| Max.output | 30-600(kg/h) |

| Max.line speed | 25(m/min) |

PRODUCTION PROCESS:

Raw materials--- Mixing --- Feeding --- Extruding ---Molding --- Calibrating --- Haul-off --- Cutting--- Stacking--- Printing or Hot stamping --- Package.

MACHINE FEATURES:

1. PVC Foam Board Machine adopts Celuka foam technology, which can produce a kind of PVC foam boards with superior quality. These processes result in a "skinning" or outer layer of foam board, thus has smooth and shining surface with characteristics of lightweight, scratch-resistant, durable, water and weather resistant, anti-corrosion, impervious to salts, insects and many chemicals including some acids.

2. PVC foam board can be100% recycled and reused. Besides, PVC foam board can be worked like wood with the tools for wood. It's suitable for sawing, cutting, nailing, screwing, planning and sticking. It's the perfect substitute for wood plates and steel plate.

3. The foam board is mostly used in transportation, advertisement, construction and furniture industry, ect.

4. The board thickness is from 3mm to 35mm, width is from 915mm to 1220mm.

EQUIPMENT LIST:

1. Double Screw Extruder 1 unit

2. Mould 1 set

3. Shaping Machine 1 unit

4. Haul-off Machine 1 unit

5. Cutting Machine 1 unit

6. Stacker 1 unit

Optional Auxiliary Machine;

1. Crusher 1 unit

2. Mixer 1 unit

3. Pulverizer 1 unit

4. Air Compressor 1 unit

TRADE TERMS:

1. Payment Term: 30% for prepayment by T/T, 70% for balanced payment by T/T, or irrevocable L/C at sight.

2. Delivery Time: 40 days after receipt of prepayment.

3. Packing Method: Packing film or wooden case

4. Guaranteed Time: 12 months