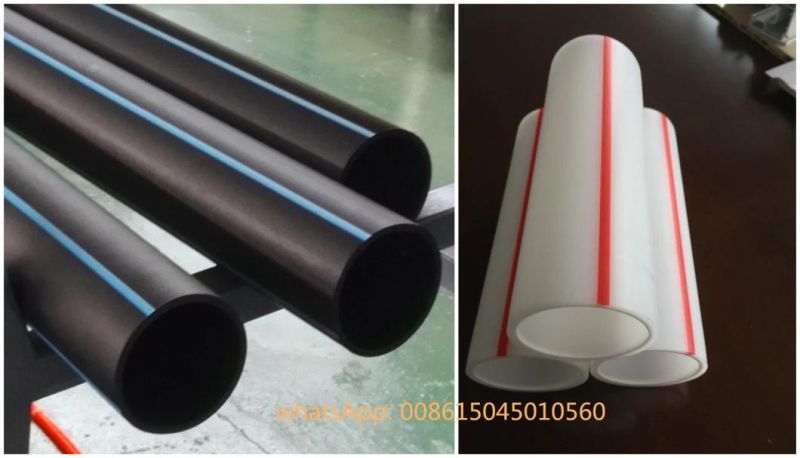

PE PP Plastic Water Gas Supply Pipe Production Extrusion Line

Qingdao Tongsan Plastic Machinery Co., Ltd.- Product Type:PE Pipe

- Screw No.:Single-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE

- Customized:Customized

Base Info

- Condition:New

- Suitable Material:PE PP PPR

- Extruder Size:Sj65,33 Extruder

- Machine Color:Customized

- Capacity:150kg,Hour

- Pipe Diameter:20-110mm

- Inverter:ABB Brand

- Temperature Control:Omron Brand

- Contractor:Siemens Brand

- PLC System:Siemens Brand

- Transport Package:Film Wrapping, Wooden Case, Strong Pallet

- Specification:20-110mm

- Trademark:Tongsan

- Origin:China

- HS Code:84772090

Description

Basic Info.

Condition New Suitable Material PE PP PPR Extruder Size Sj65/33 Extruder Machine Color Customized Capacity 150kg/Hour Pipe Diameter 20-110mm Inverter ABB Brand Temperature Control Omron Brand Contractor Siemens Brand PLC System Siemens Brand Transport Package Film Wrapping, Wooden Case, Strong Pallet Specification 20-110mm Trademark Tongsan Origin China HS Code 84772090Product Description

PE PP PPR Water/ Gas pipe Extrusion LineThe production line adopts unique mold and sizing sleeve design, which can produce PE/HDPE solid pipe continuously and stably. PE/HDPE pipe has the features of good low-temperature impact resistance, good resistance to stress cracking, corrosion resisitance, non-toxicity flexibility etc.Widely used in water supply, water drainage, gas transmission, threading and other fields.

The main machine adopts screws specially used for polylefi. It processes features of high production, good plasticization and stable extruding. It is equipped with autimatic wacuum material feeder and automatic constant temperature drying hopper.

Die heads of helical type and basket type are perfect for polyolefin, and can help to produce sound melting pressure, and improve the plasticization capacity. Meanwhile, stable material-flow and pressure grade can be guaranteed.

Advanced vacuum calibrating method improves the cleanliness and hardness of surace. Reasonable high-speed sprinkling cooling water tank guarantees the pipe quality and high speed stable extruding.

Caterpilar of the hauling machine adopts anti-abrasion alloy material, which realizes stable traction, wide frequency adjustment range and long lifespan.

New generation auto cutting blade realizes smooth cutting surface, high precision and low noise.